A V-shaped metal rubber spring automatic mold opening and closing mold and automatic mold opening and closing method

An automatic opening and closing, metal rubber technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of high labor intensity, low production efficiency, and easy damage of products, so as to reduce the labor intensity of operation and improve production efficiency , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

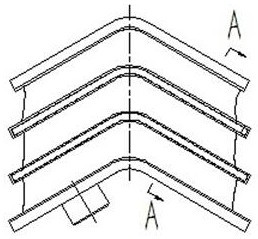

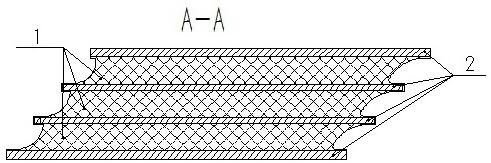

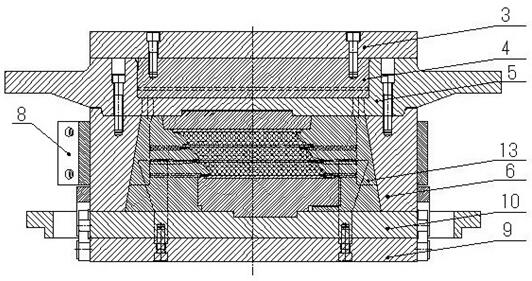

[0034] This embodiment provides a V-shaped metal rubber spring automatic mold opening and closing mold, including an upper mold assembly and a lower mold assembly; such as image 3 As shown, the upper mold assembly includes a top plate 3, a plastic injection plug 4, a plastic injection cylinder 5, a middle mold 6, an upper insert 7 and a middle mold heating ring 8; The plug 4 extends into the glue injection cylinder 5, the glue injection cylinder 5 and the middle mold 6 are spliced and positioned by the frustum and fixed by bolts, and the upper insert 7 is fixed with the glue injection cylinder 5 by screws;

[0035] The top plate 3 is fastened under the heating plate on the vulcanizing machine, and the glue injection cylinder 5 is connected with the hanging formwork on the vulcanizing machine through bolts;

[0036] like image 3 and Figure 4 As shown, the lower die assembly includes a bottom die 9, a support plate 10, two side inserts 11, a lower insert 12 and a flap die...

Embodiment 2

[0046] The present embodiment provides an automatic mold opening and closing method for automatically opening and closing a mold for a V-shaped metal rubber spring, using the V-shaped metal rubber spring described in Embodiment 1 to automatically open and close the mold, and the specific steps are:

[0047] S1. After the vulcanization of the product is completed, the lower heating plate of the vulcanizer drives the lower die assembly to move downward, and the lower insert 12 pulls the segment mold combination to move down to realize the combination of the middle die 6 and the segment die Open;

[0048] S2. Start the vulcanizing machine to move down the hanging mold frame, and the glue injection cylinder 5 and the middle mold 6 move downward, so that the glue injection cylinder 5 and the glue injection plug 4 are opened;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com