Automatic clamping platen device

An automatic clamping and pressing plate technology, applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of complex structure, high manufacturing cost, few clamping points, etc., and achieve simple structure and low manufacturing cost. , the effect of short clamping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

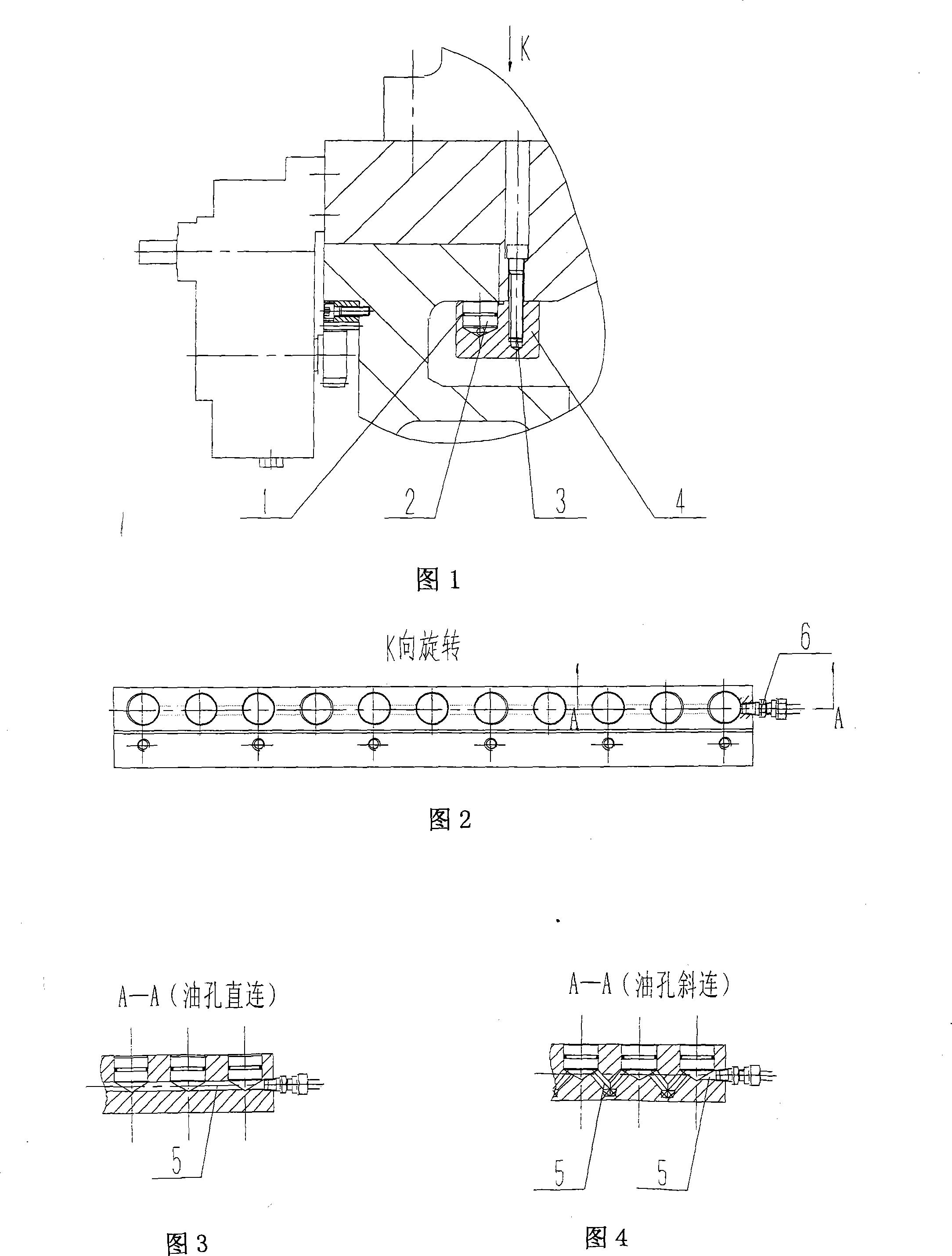

[0025] As shown in Figures 1, 2, 3, and 4, the present invention includes a pressing plate 4 fastened on the moving saddle by screws 3, each pressing plate body round hole distributed on the pressing plate 4 and the clamp installed in the pressing plate body round hole Press piston 2 to form each one-way oil cylinder. The clamping piston 2 is sealed and connected with the circular holes of the pressing plate body distributed on the pressing plate 4 through the sealing ring 1 . The one-way oil cylinders are connected to each other through the oil passages 5 in the pressure plate body, and the oil passages 5 connected to each one-way oil cylinders are connected by oblique holes or straight holes between each one-way oil cylinders. A pipe joint 6 is installed at the end of the pressure plate 4, and the pipe joint 6 connects the external oil circuit with the oil channel 5 in the pressure plate 4 body. The hydraulic oil is controlled by electricity, enters the pressure plate body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com