Surface treatment method of titanium material for electrodes

a surface treatment method and electrode technology, applied in heat treatment equipment, furnaces, manufacturing tools, etc., can solve problems such as oxygen deficiency type titanium oxide layers, and achieve excellent electrical conductivity, corrosion resistance, and hydrogen absorption resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0053]Below, Examples whereby the advantages of the present invention have been confirmed will be described by comparison with Comparative Examples not satisfying the requirements of the present invention.

first example

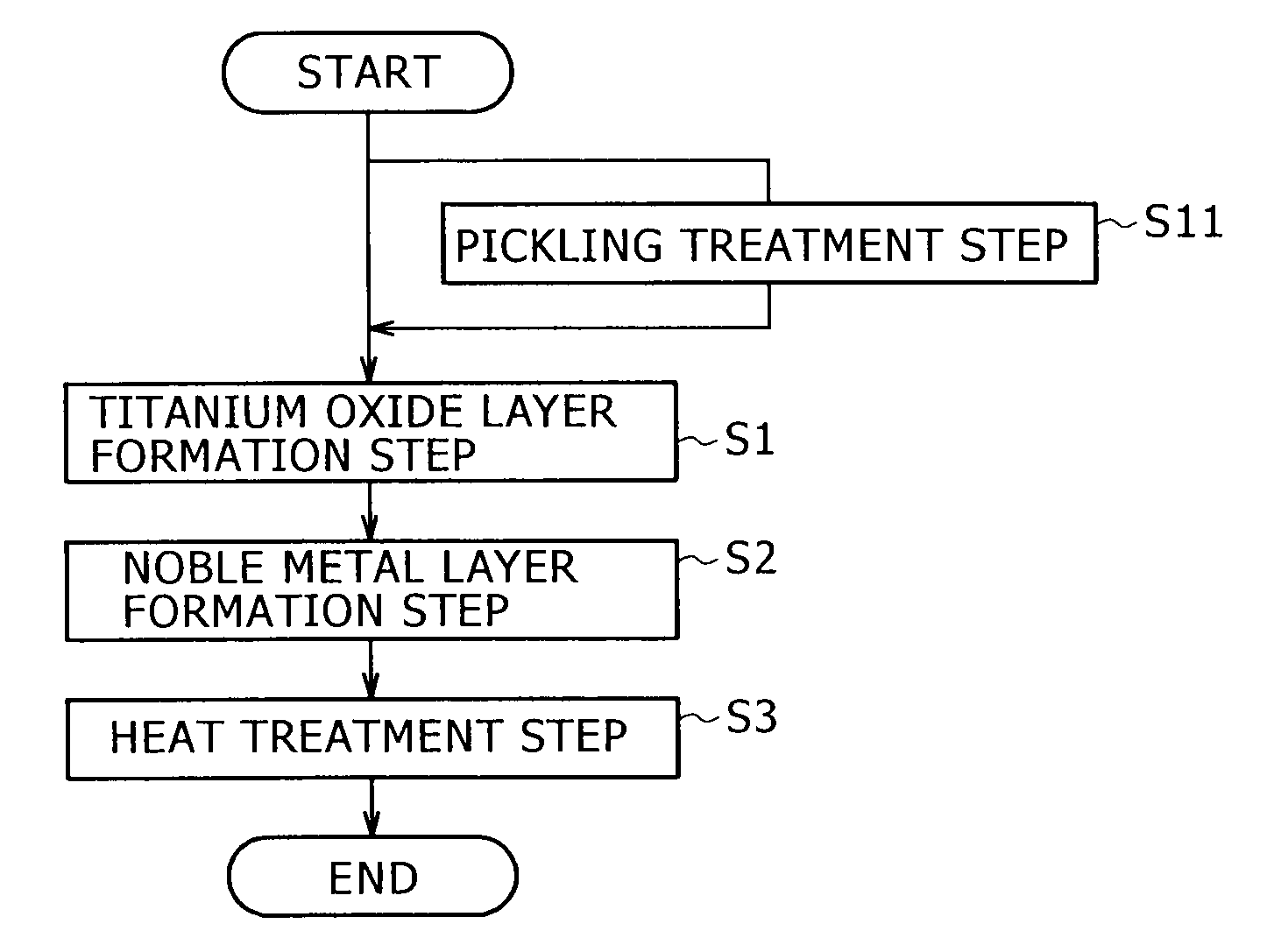

[0054]In First Example, the surface treatment method by a heat treatment in an air atmosphere as the titanium oxide layer formation step S1 was evaluated.

(Surface Treatment of Test Plate)

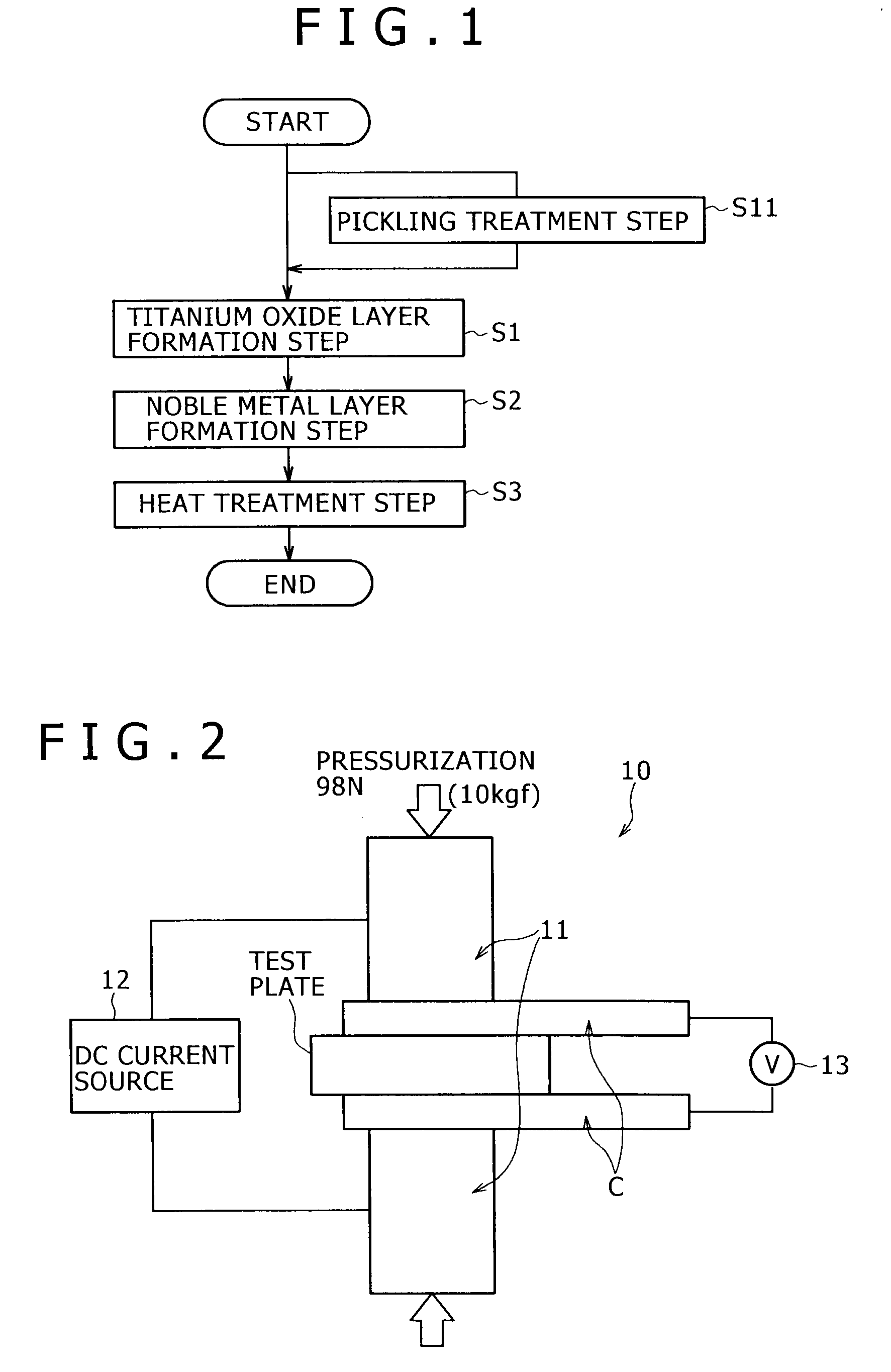

[0055]The test plate used was treated in the following manner. First, a titanium material (2 cm in width×5 cm in length×0.2 mm in thickness) formed of class 1 pure titanium specified according to JIS H 4600 was, as the pickling treatment step S11, subjected to ultrasonic cleaning in acetone. Then, the titanium material was subjected to a pickling treatment in a mixed aqueous solution of 1 mass % hydrofluoric acid and 5 mass % nitric acid, and cleaned with pure water, and dried. Then, as the titanium oxide layer formation step S1, a heat treatment in an air atmosphere was carried out under the heat treatment conditions (temperature and time) shown in Table 1. The thickness of the titanium oxide layer formed on the heat treated test plate surface was measured by observation under a transmission electr...

second example

[0071]In Second Example, evaluation of the surface treatment method by an anodic oxidation treatment as the titanium oxide layer formation layer S1 was carried out.

(Surface Treatment of Test Plate)

[0072]Each used test plate was treated in the following manner. First, a titanium material (2 cm in width×5 cm in length×1 mm in thickness) formed of class 1 pure titanium specified according to JIS H 4600 was, as the pickling treatment step S11, subjected to ultrasonic cleaning in acetone. Then, the titanium material was subjected to a first pickling treatment in a 4 mass % hydrofluoric acid aqueous solution. Then, the titanium material was subjected to a second pickling treatment in a mixed aqueous solution of 0.5 mass % hydrofluoric acid and 5 mass % hydrogen peroxide, and then cleaned with pure water, and dried. Then, as the titanium oxide layer formation step S1, an anodic oxidation treatment was carried out at the voltage and for the holding time shown in Table 2 in a room-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com