Contact for a semiconductor light emitting device

a light-emitting device and semiconductor technology, applied in the field of ##light-emitting diodes, can solve the problems the use of thick semiconductor layers has several disadvantages, etc., and achieves the effect of reducing reducing the contact resistance, and improving the reflectivity of the conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Depending on the context, as used herein, “AlGaInP” may refer in particular to a quaternary alloy of aluminum, indium, gallium, and phosphorus, or in general to any binary, ternary, or quaternary alloy of aluminum, indium, gallium, and phosphorus. Depending on the context, as used herein, “contact” may refer in particular to a metal electrode, or in general to the combination of a semiconductor contact layer, a metal electrode, and any structures disposed between the semiconductor contact layer and the metal electrode.

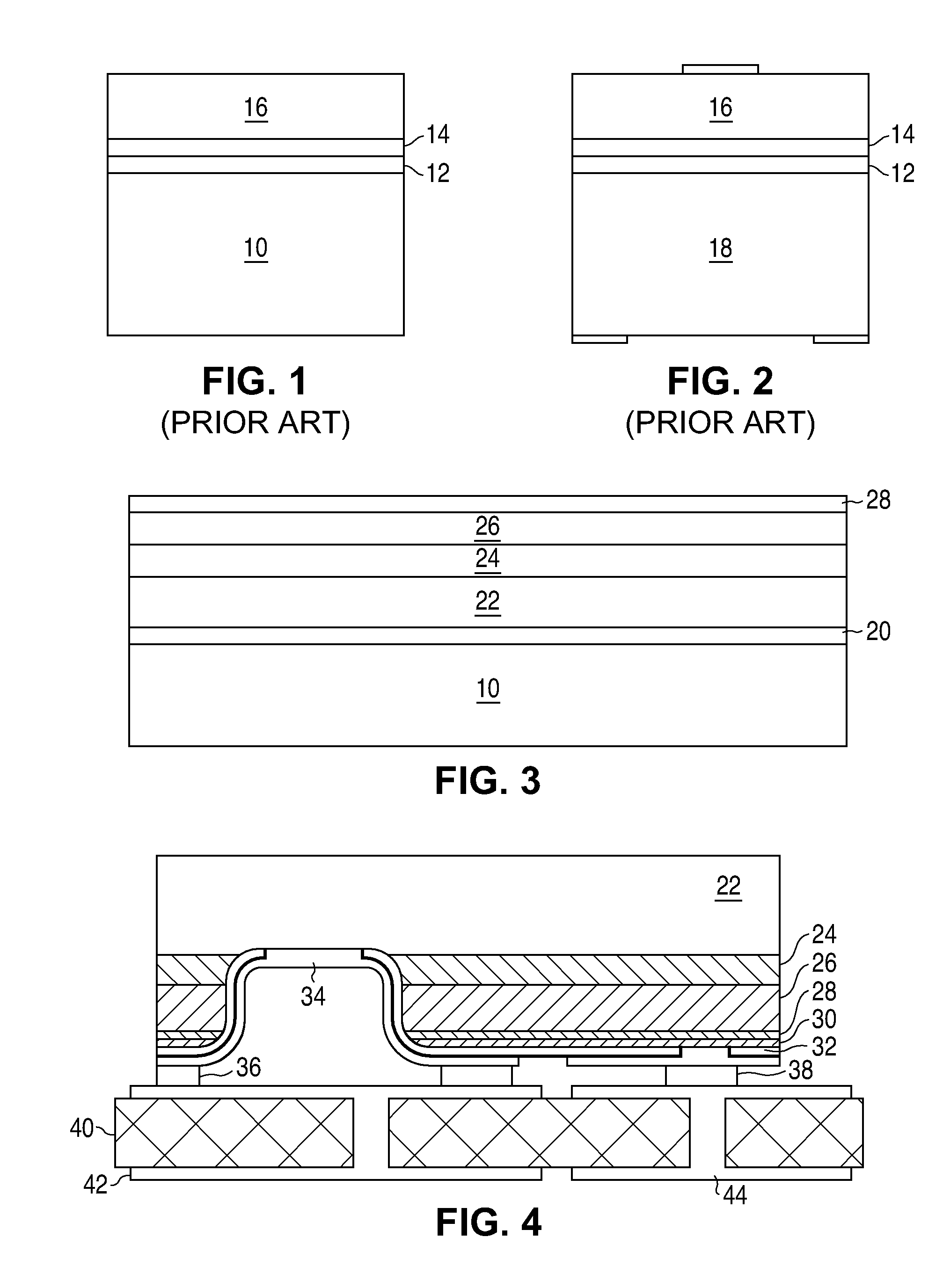

[0015]As described above, AlGaInP devices have conventionally included thick layers, particularly on the p-side of the light emitting region, for current spreading, due to the low mobility of holes in p-type AlGaInP material. Thinner p-type layers have generally not been used due to the difficulty of achieving high hole concentrations in AlGaInP.

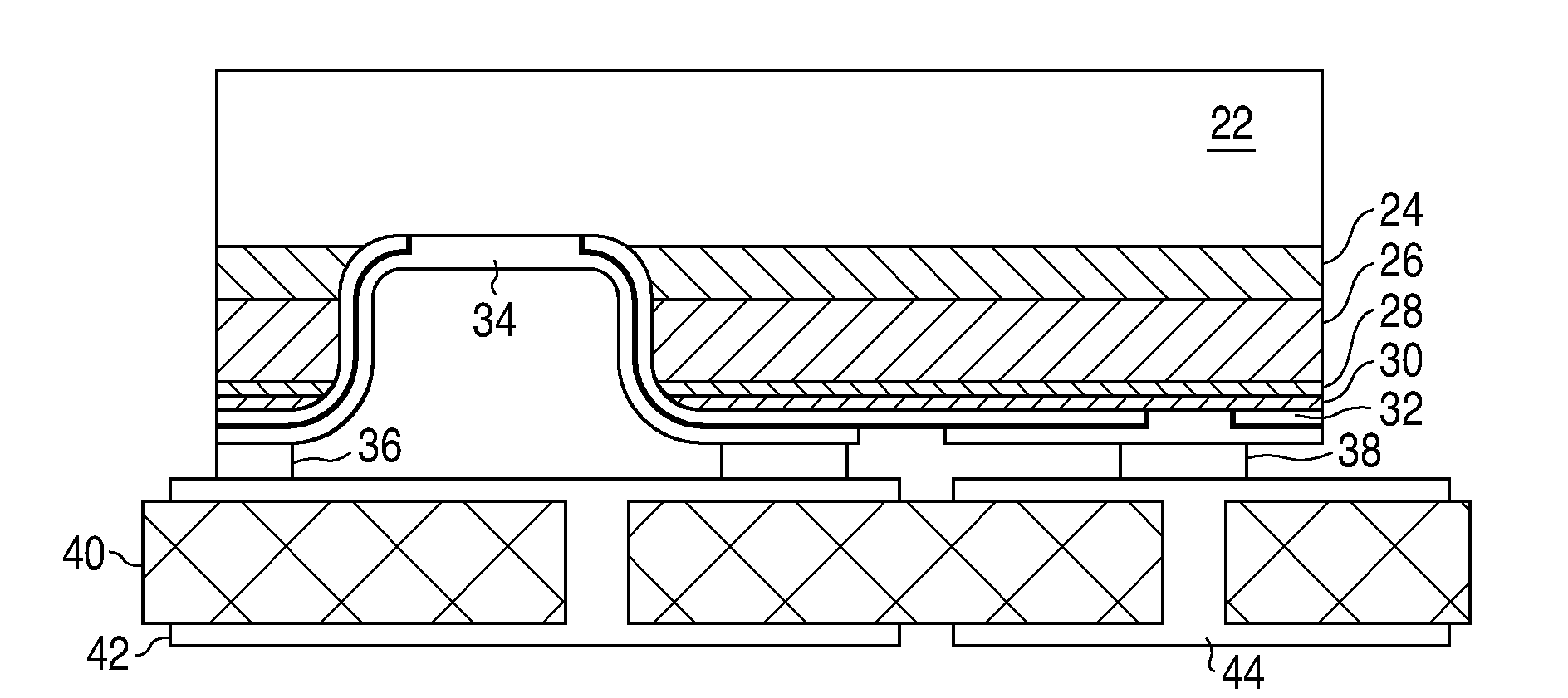

[0016]In accordance with embodiments of the invention, an AlGaInP light emitting device includes a highly doped, thin p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com