Exhaust gas purification system and method for purifying exhaust gas

a technology of exhaust gas and purification system, which is applied in the direction of machines/engines, electrochemical generators, separation processes, etc., can solve the problems of reducing the energy efficiency of the system having the internal combustion engine, and combusting fuel and emitted exhaust gases, so as to achieve the effect of not reducing the energy efficiency or increasing the size of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

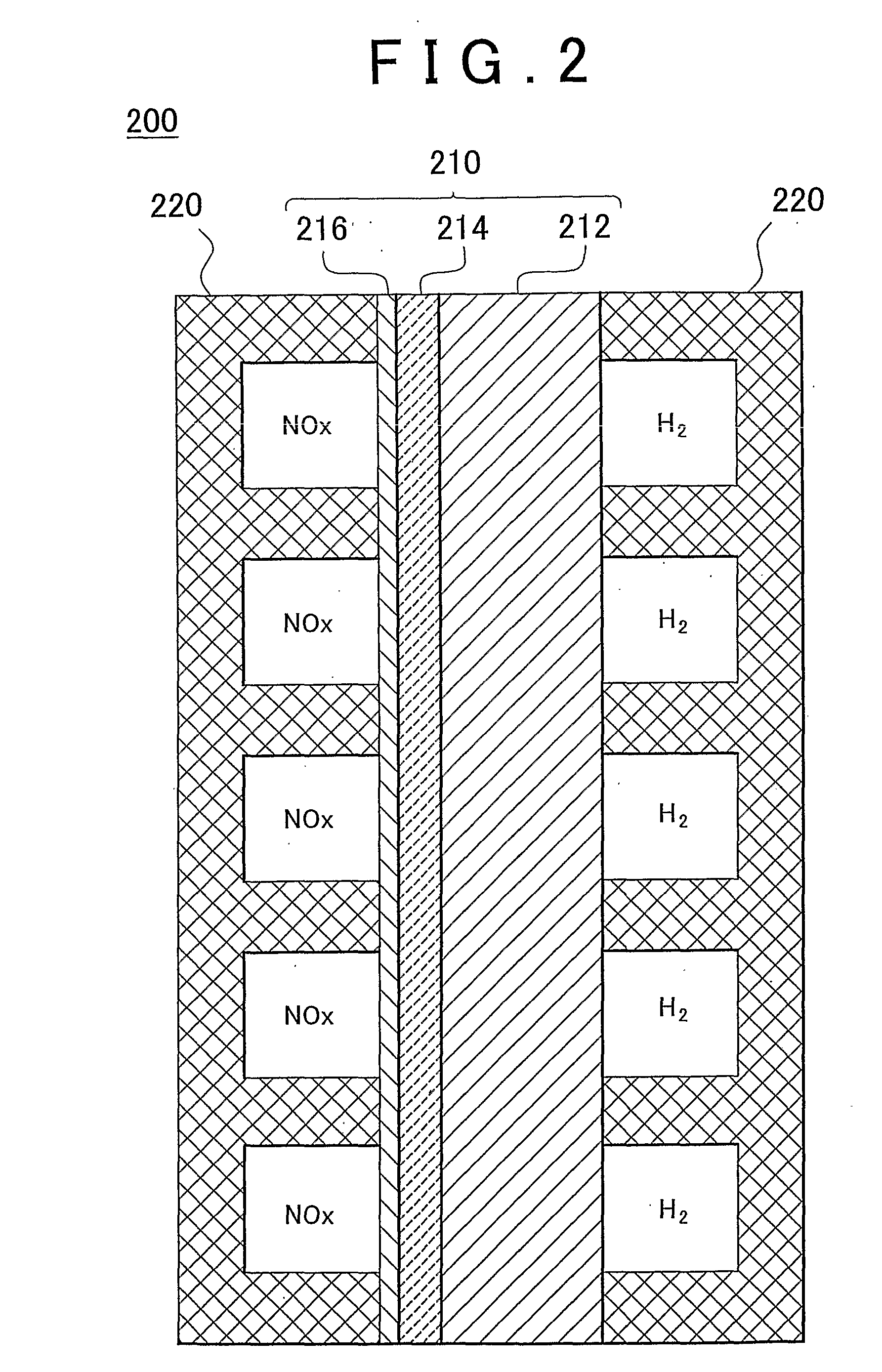

[0019]In the following description and the accompanying drawings, the present invention will be described in the order of an exhaust gas purifying system, a fuel cell, and variations, in more detail in terms of example embodiments.

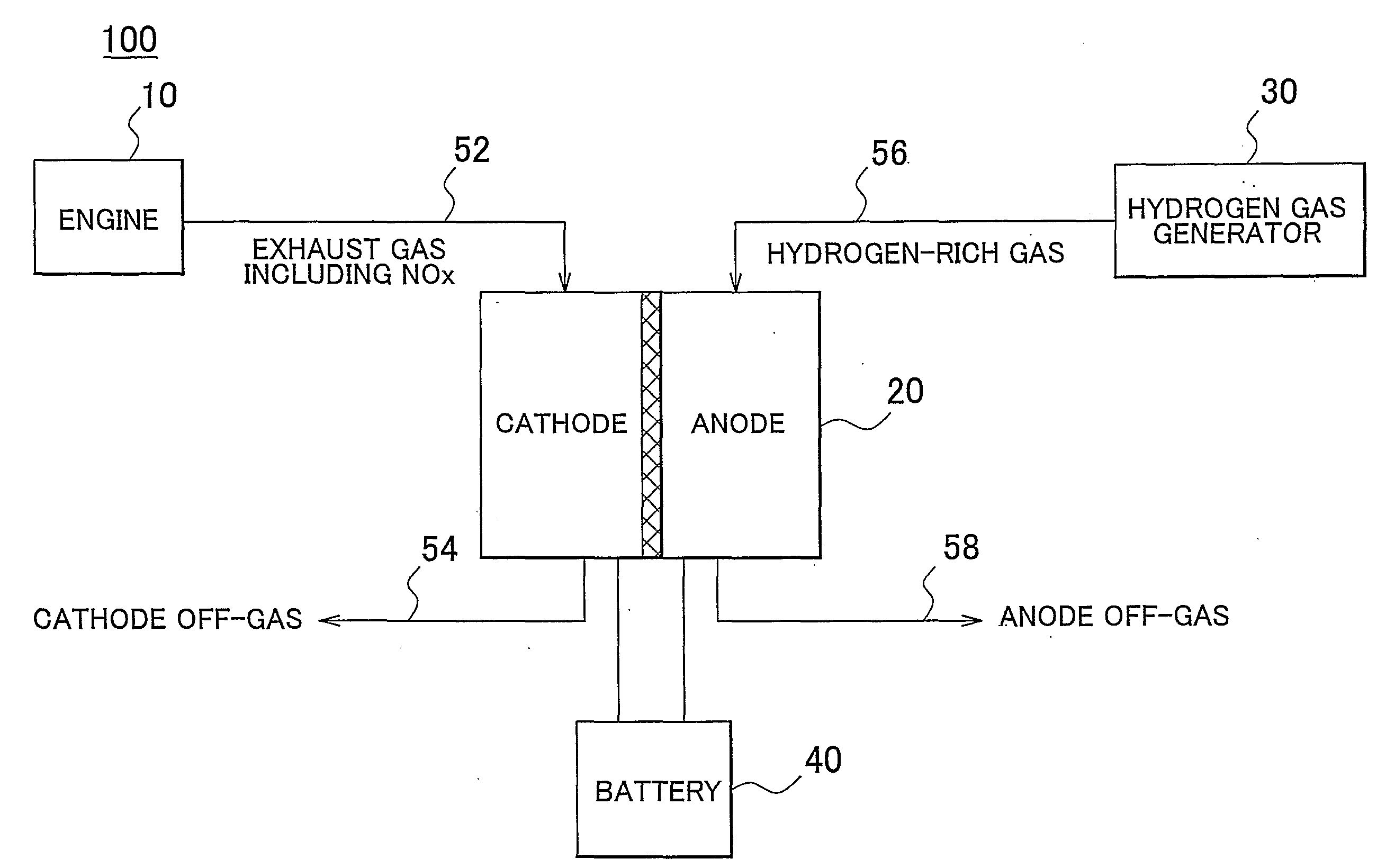

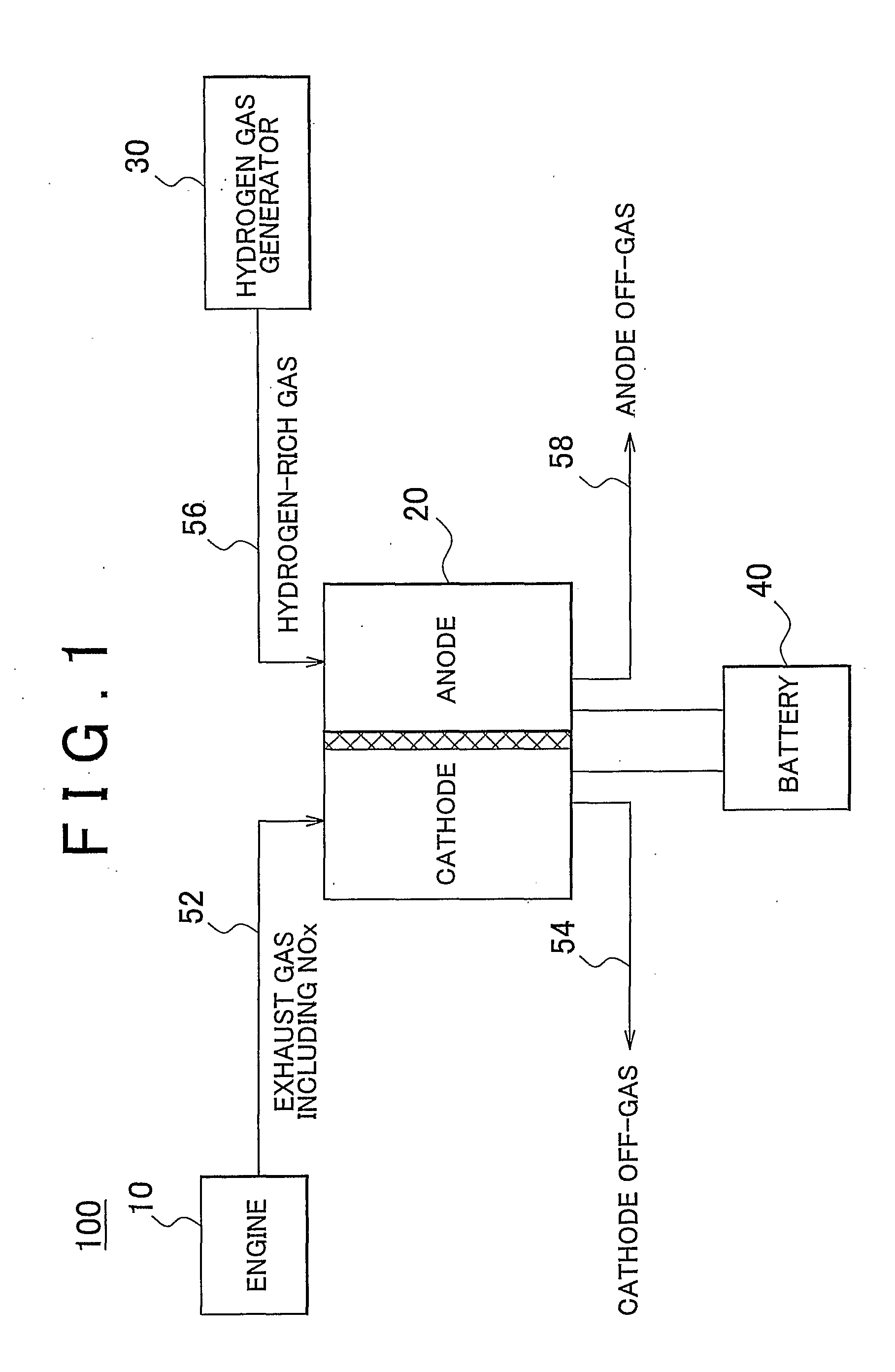

[0020]FIG. 1 is a diagram showing a schematic view of the exhaust gas purifying system 100 according to one example embodiment of the present invention. The exhaust gas purifying system 100 is installed in a vehicle that uses an internal combustion engine as a driving power source.

[0021]As shown in FIG. 1, the exhaust gas purifying system 100 has an engine 10, a fuel cell 20, a hydrogen gas generator 30, and a battery 40.

[0022]The engine 10 combusts gasoline supplied from a gasoline tank (not shown), and emits exhaust gas. The temperature of the exhaust gas is approximately 400° C. The exhaust gas contains nitrogen oxides (NOx). These nitrogen oxides, as described below, are decomposed electrochemically by the fuel cell 20.

[0023]The hydrogen gas generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com