Pumpless liquid cooling system

a liquid cooling system and pumpless technology, applied in indirect heat exchangers, laminated elements, light and heating apparatuses, etc., can solve the problems of large volume of liquid cooling systems, inability to meet the needs of traditional air cooling, and occupying more space in electronic systems,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

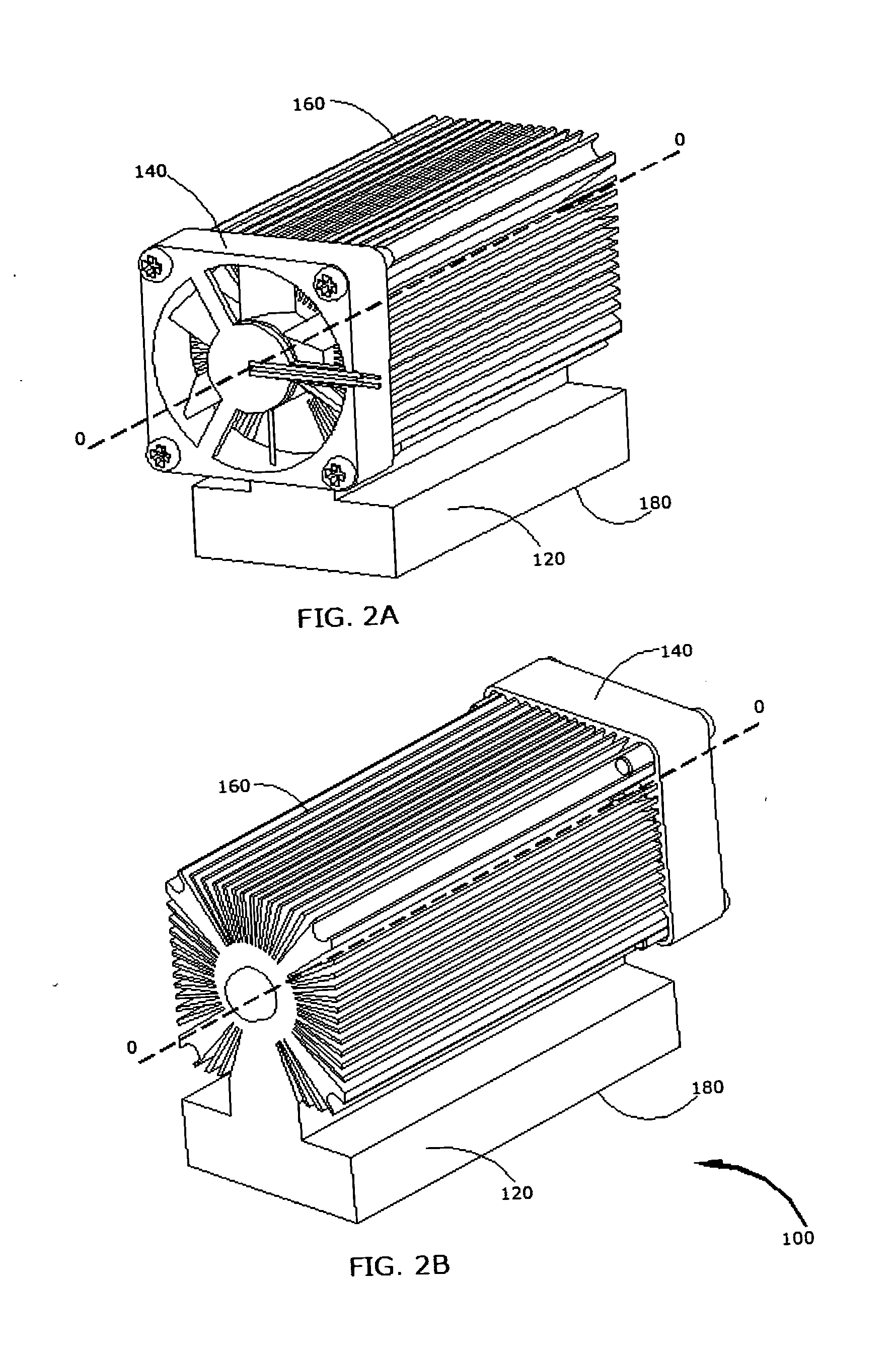

[0025]Referring initially to FIGS. 1A and 1B, illustrated are examples of prior art integrated liquid cooling systems 800, 900. The prior art integrated liquid cooling system 800 illustrated in FIG. 1A has a heat absorbing unit 4 containing coolant therein and a heat dissipating unit 2 having a liquid circulating module in communicating with heat absorbing unit 4 via two pipes 100 and 200. The heat generating component 6 is in contact with heat absorbing unit 4. Heat dissipating unit 2 having fan and a plurality of fins (not shown here) to reject heat absorbed by heat absorbing unit 4 and carried by the coolant circulated by a pump (not shown here). Apparently this integrated liquid cooling system has the disadvantages of: 1) having pipes or tubes and fitting for the connections; 2) lack of compact solid construction since the heat absorbing unit and the heat dissipating unit are separated and connected with tubes; 3) having a pump with higher cost and acoustic noise.

[0026]FIG. 1B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com