Fiber-cement/gypsum laminate

a fiber cement and gypsum technology, applied in the field of single-piece laminate composite building materials of fibercement and gypsum, can solve the problems of poor abuse resistance of gypsum compared to other wallboard materials, easy damage to the paper surface of gypsum wallboard, and typical wall abuse, etc., to achieve good abuse resistance and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention illustrated below describe a single piece laminate composite wallboard system. It will be appreciated, however, that the present invention is not limited to wallboards, but can be utilized for any application where an abuse resistant, impact resistant and fire resistant building material is desired.

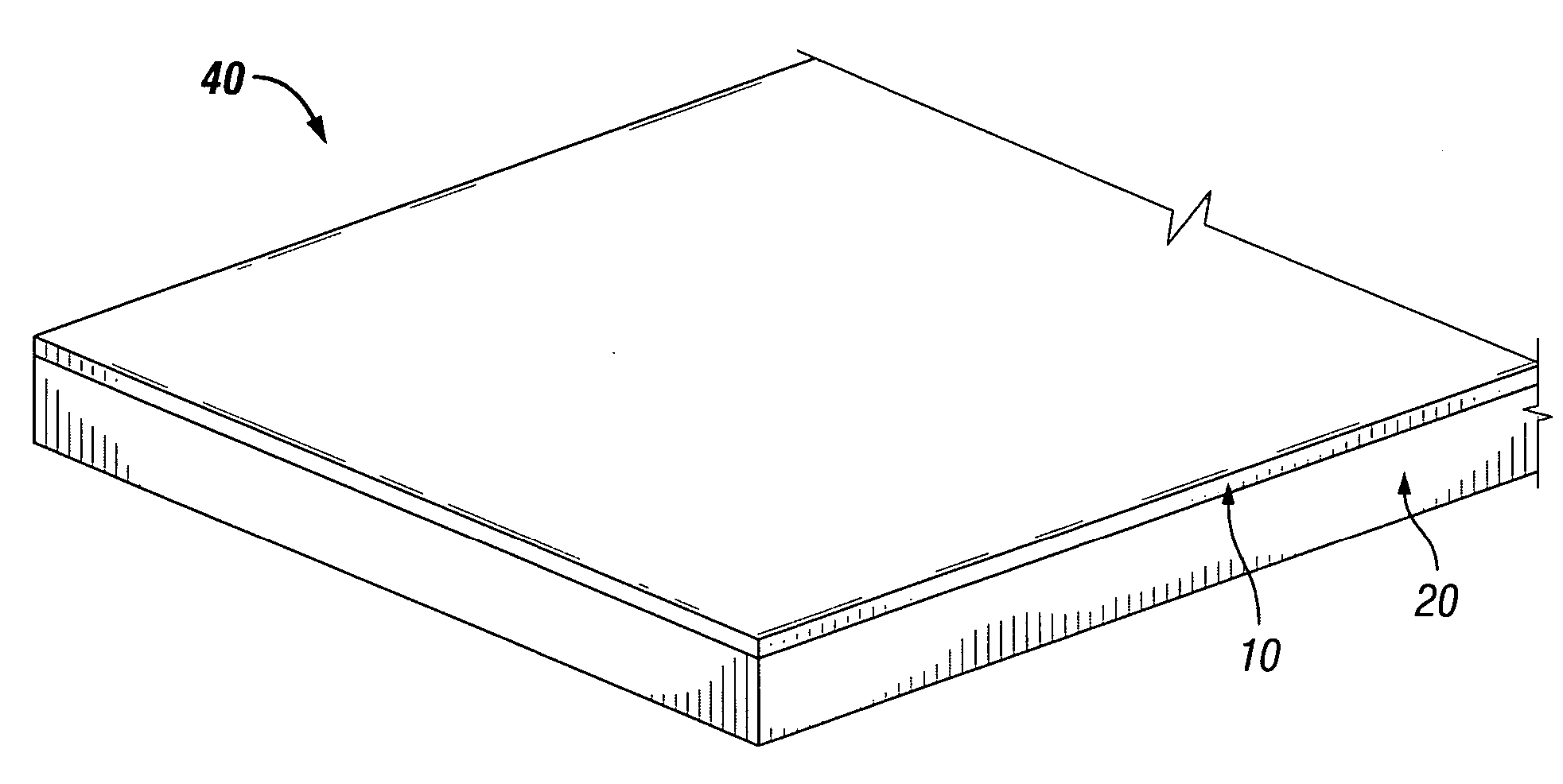

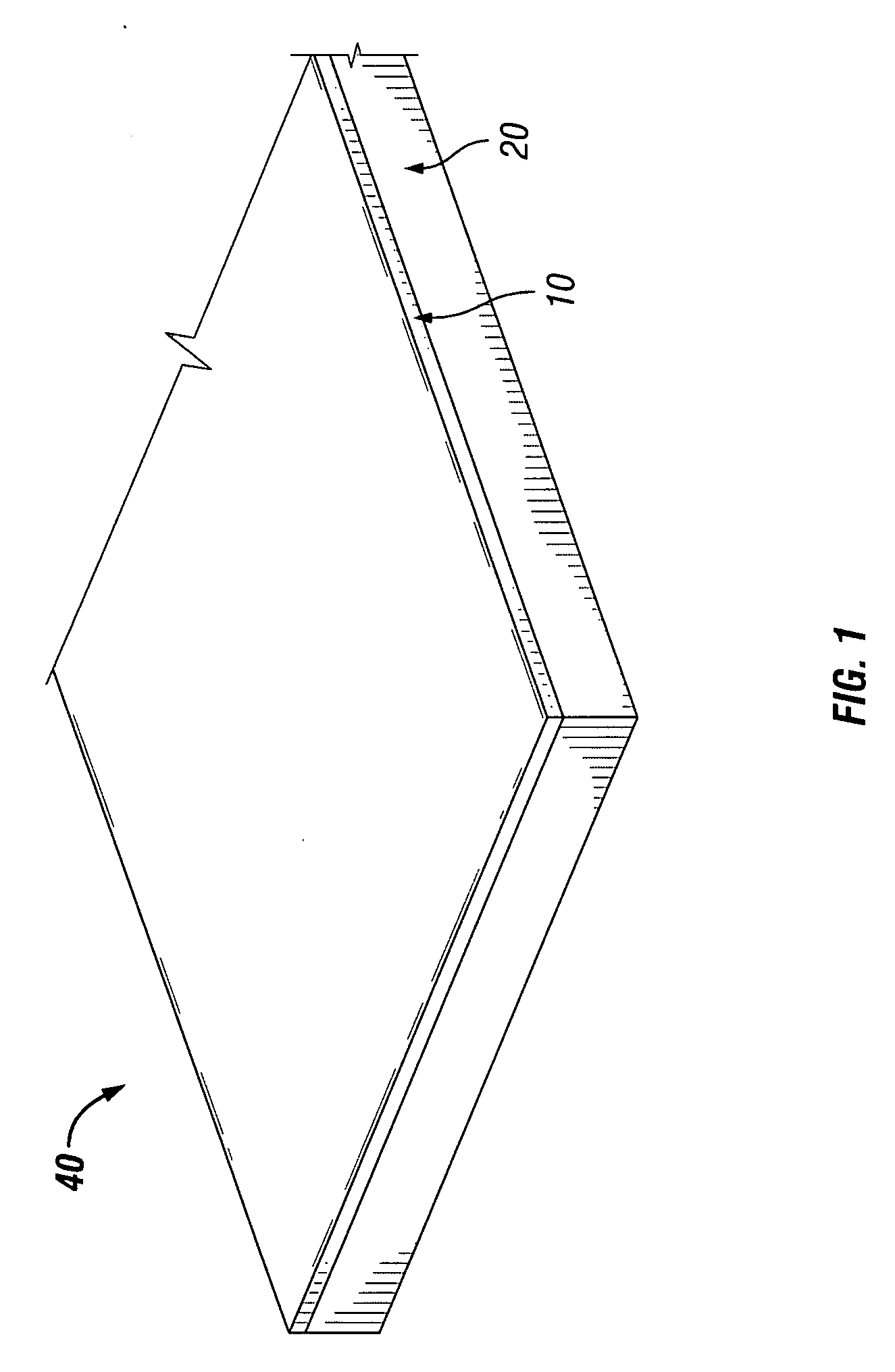

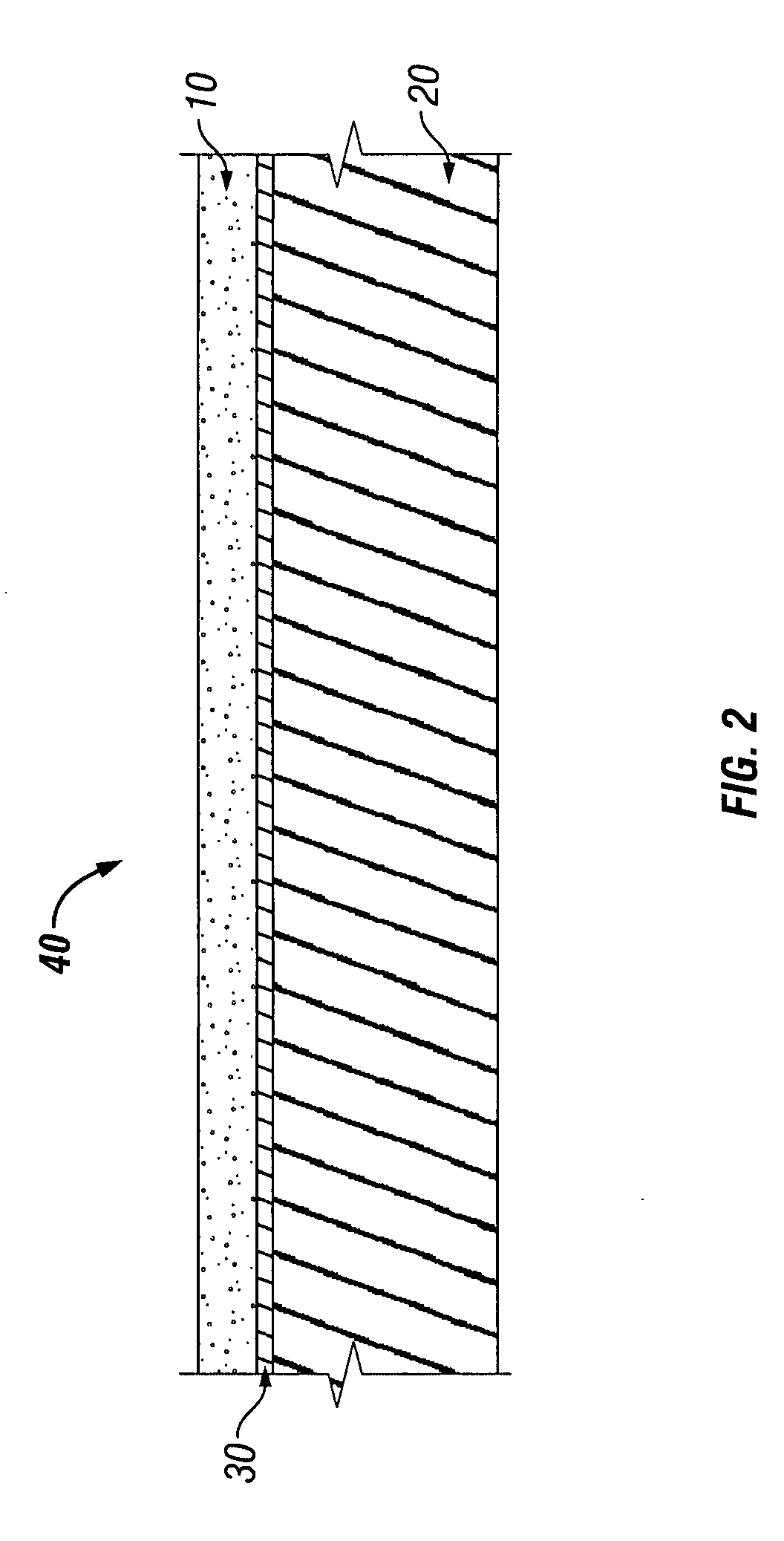

[0016] As seen in FIG. 1, a preferred building material 40 is comprised of a fiber-cement layer 10 laminated to gypsum layer 20, creating a single piece laminate composite. FIG. 2 illustrates that the fiber cement layer 10 may be laminated to the gypsum layer 20 using an adhesive 30, the thickness of which is exaggerated in FIG. 2 for illustration purposes, as described in further detail below. It will be appreciated that the fiber-cement and gypsum components can take any form necessary, including, but not limited to, panels, sheets, skins, boards, or the like. In one preferred embodiment, the thickness of a fiber-cement sheet 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com