Methods of separating fat from non-soy plant materials and compositions produced therefrom

a technology of non-soy plant materials and compositions, applied in the field of oileeds, can solve the problems of inability to produce certified organic food products, inability to use solvents, and relatively inefficient oil recovery from extruder press methods, and achieve the effect of reducing fa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

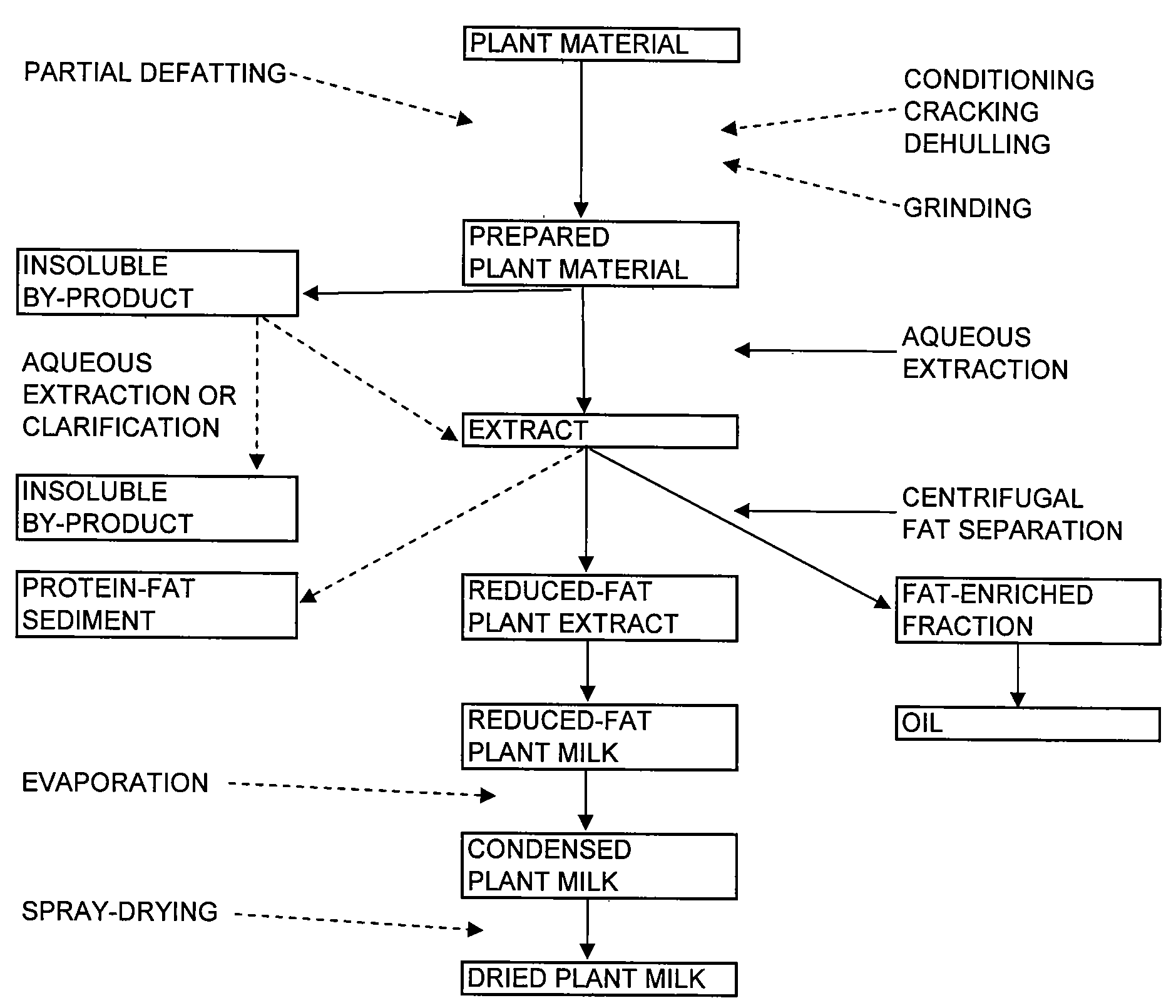

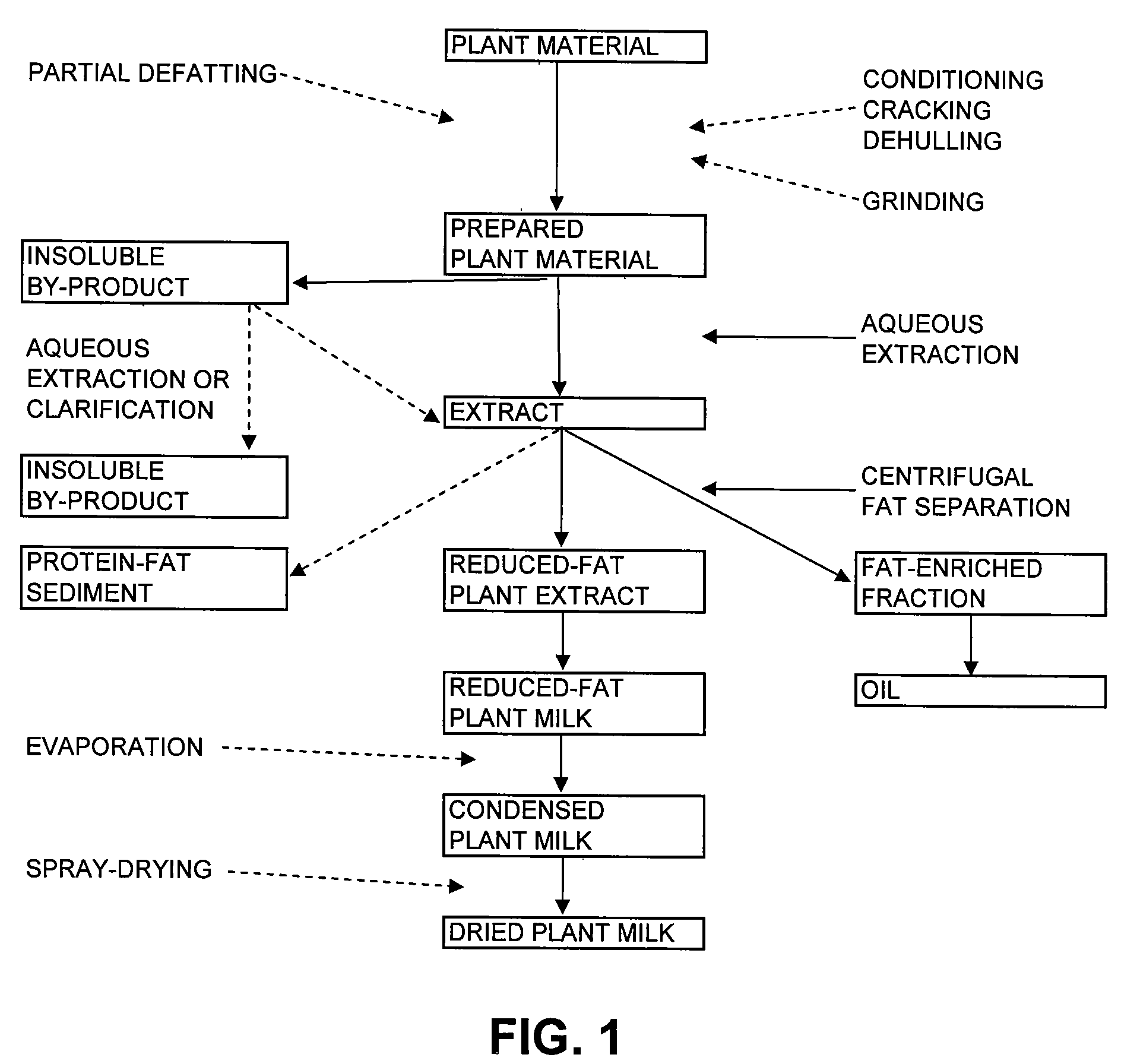

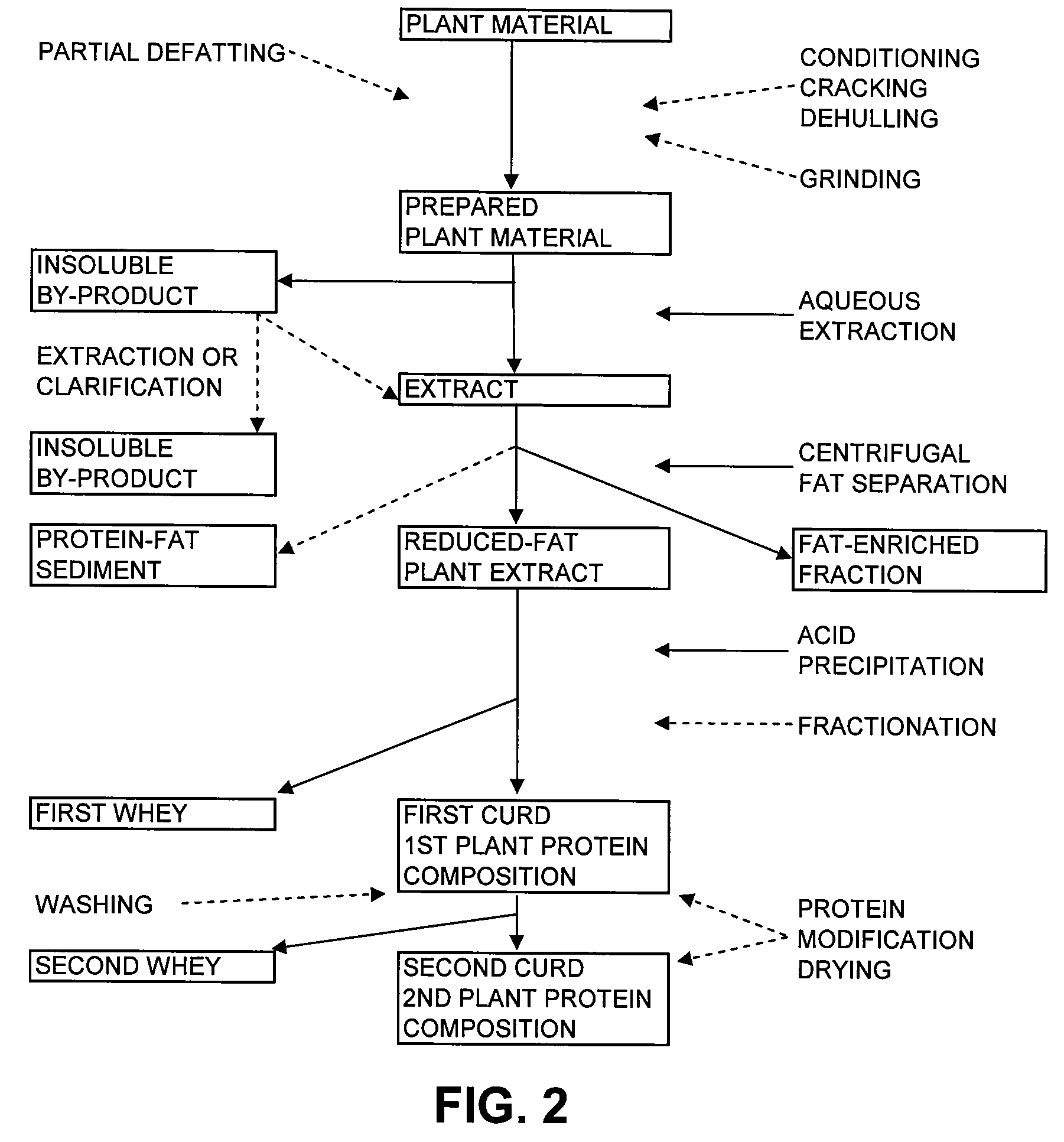

Method used

Image

Examples

example 1

Preparation of Reduced-Fat Canola Protein Compositions and Canola Cream from Canola Seeds.

[0052]Organically certified canola seeds were obtained from Montana Specialty Mills, Great Falls, Mont. and were milled to 400 mesh flour using a grinding mill (model DNWA Buhler, Minneapolis, Minn.). The full fat canola flour contained 5.2% moisture, 24.2% dry basis Kjeldahl protein, and 49.0% dry basis acid hydrolyzed fat for a protein to fat ratio of 0.49 to 1.

[0053]In this and all subsequent examples, the dry basis protein and fat ratios were measured by standard methods. The protein content of the soy materials was determined using the Kjeldahl method (AOAC 18th Ed. Method 991.2.2, Total Nitrogen in Milk, 1994, which is incorporated herein by reference in its entirety). Briefly, samples were digested using acid, catalyst and heat. The digested sample was made alkaline with the addition of sodium hydroxide. Steam was then used to distill the sample, releasing ammonia. The ammonia was collec...

example 2

Preparation of Reduced Fat Protein Products and Sunflower Cream from Raw Sunflower Seeds.

[0058]Raw sunflower kernels (SL80) were obtained from Dakota Gourmet (SunOpta, Wahpeton, N. Dak.). The raw sunflower kernels were ground with a grinding mill (All-Grain-Company model A-22, Brigham City, Utah) to produce 60 mesh sunflower flour. The sunflower flour had proximate analysis of 4.7% moisture, 27.6% dry basis Kjeldahl protein, 54.5% dry basis acid hydrolyzed fat and a 0.50 to 1 protein to fat ratio.

[0059]Twenty pounds of sunflower flour was extracted with 200 pounds of water at 140° F. in a 50 gallon agitated tank. The pH of the extraction slurry was adjusted to 7.1 by addition of 0.033 pounds of calcium hydroxide and held for a mean time of 0.75 hour. The extract was separated from the insoluble by-product by centrifuging at 4390 rpm in a Sharples P-660 decanting centrifuge (Alfa Laval Separation Inc., Warminster, Pa.) at an extract flow rate of 5 pounds per minute. Twenty-two pounds...

example 3

Preparation of Reduced-Fat Hemp Protein Compositions and Hemp Cream from Milled Hemp Seeds.

[0062]Milled hemp seeds were obtained from Manitoba Harvest, Winnipeg, Manitoba, Canada and the milled hemp seeds contained 5.8% moisture, 33.4% dry basis Kjeldahl protein, 45.1% dry basis acid hydrolyzed fat and a 0.74 to 1 protein to fat ratio.

[0063]Fifty pounds of the hemp seed was mixed with 320 pounds of water at 125° F. in a 50 gallon agitated tank. The hemp slurry was continuously recirculated from the tank to a colloid mill and back into the tank at a rate of 5 gallons per minute for 30 minutes to wet mill the seeds. One hundred sixty pounds of additional water was added to the slurry, and the pH of the extraction slurry was adjusted to 7.5 with the addition of a 10% solution of sodium hydroxide (50% solution, Fisher Scientific, Barnstead International, Dubuque, Iowa). The diluted slurry was held for a mean time of 20 minutes. The extract was separated from the insoluble by-product usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com