Polymeric hollow fiber heat exchange systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

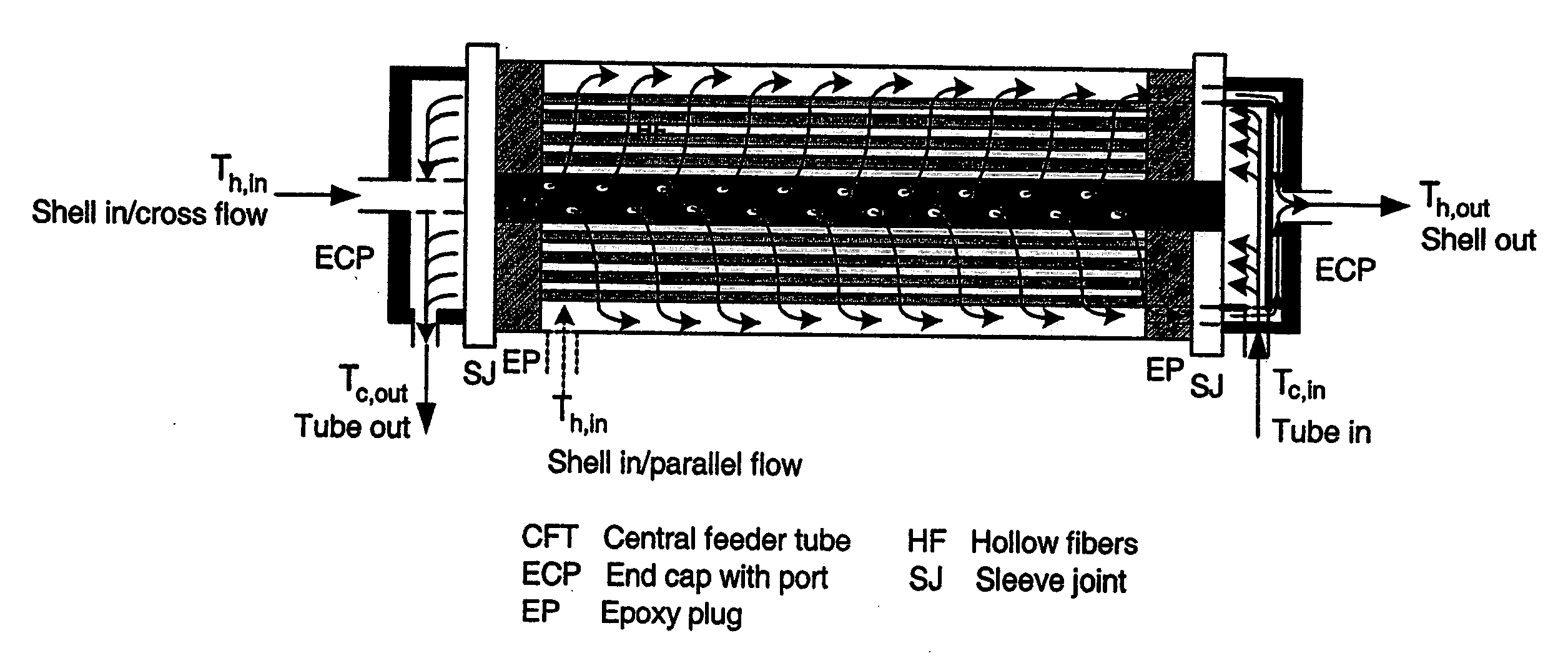

[0046] As noted above, the present disclosure provides advantageous heat exchange systems that include one or more polymeric solid hollow fibers and, more particularly, asymmetric porous hollow fiber heat exchange systems that provide enhanced heat transfer in a variety of applications, e.g., desalination applications, solar heating applications, applications in the chemical industry, applications in the biomedical industry and / or applications in the biotechnology industry. Exemplary embodiments of the disclosed heat exchange systems are characterized by hollow fibers that include a microporous wall and a dense skin formed thereon, thereby preventing liquid transmission and / or contamination through the wall of the hollow fiber while simultaneously enhancing heat transfer based on the presence of liquid molecules within the porous substructure of the hollow fiber. The disclosed heat exchange systems advantageously provide improved processing performance and reduced cost for industri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com