Absorber plate core for flat plate solar thermal collector and solar thermal collector

A solar collector and heat absorbing panel core technology is applied to solar collectors, solar thermal energy, solar collectors using working fluid, etc. to achieve the effects of low processing cost, high thermal efficiency, and enhanced heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 Shown, process a kind of solar heat collector heat-absorbing plate core that the present invention provides.

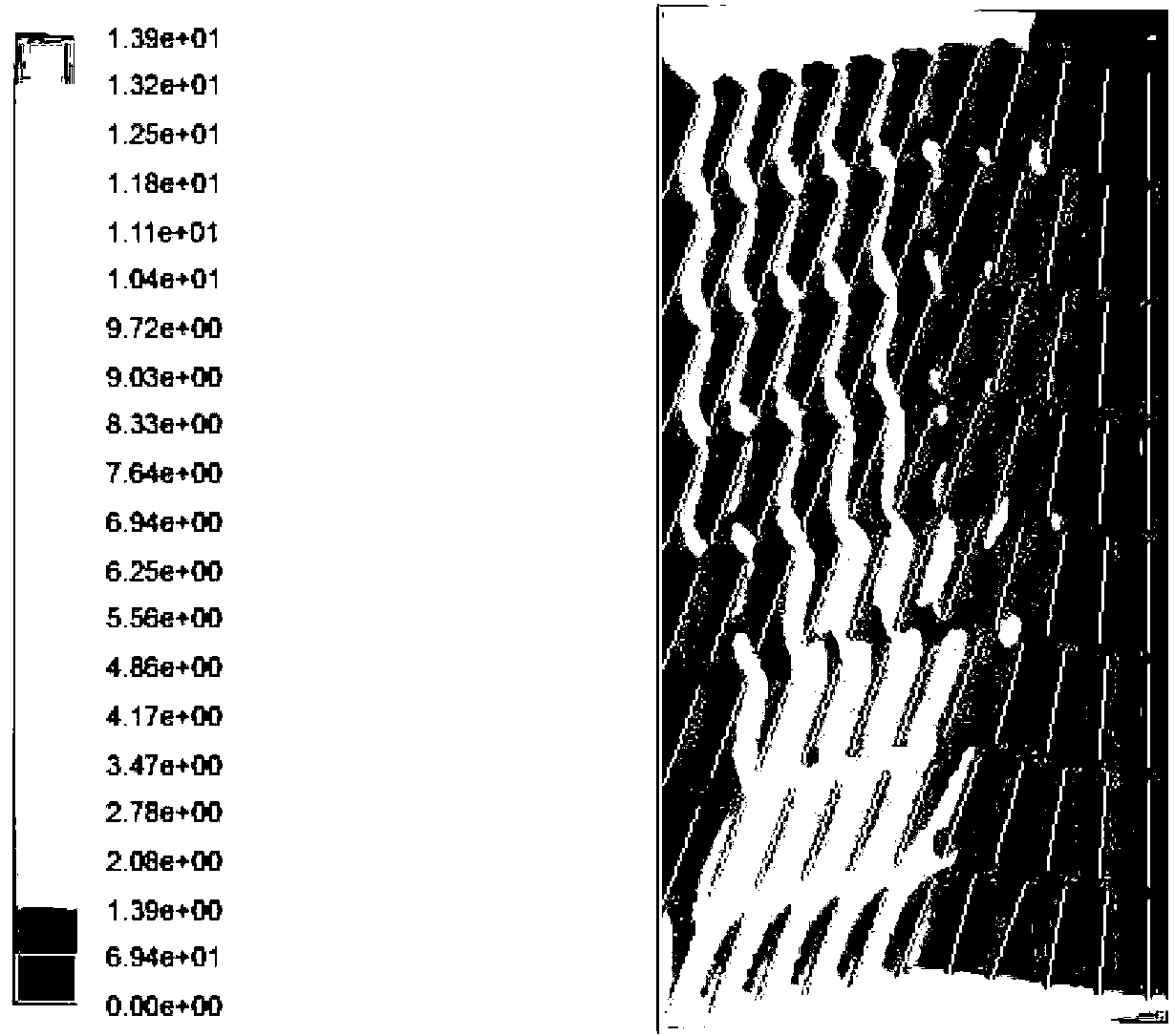

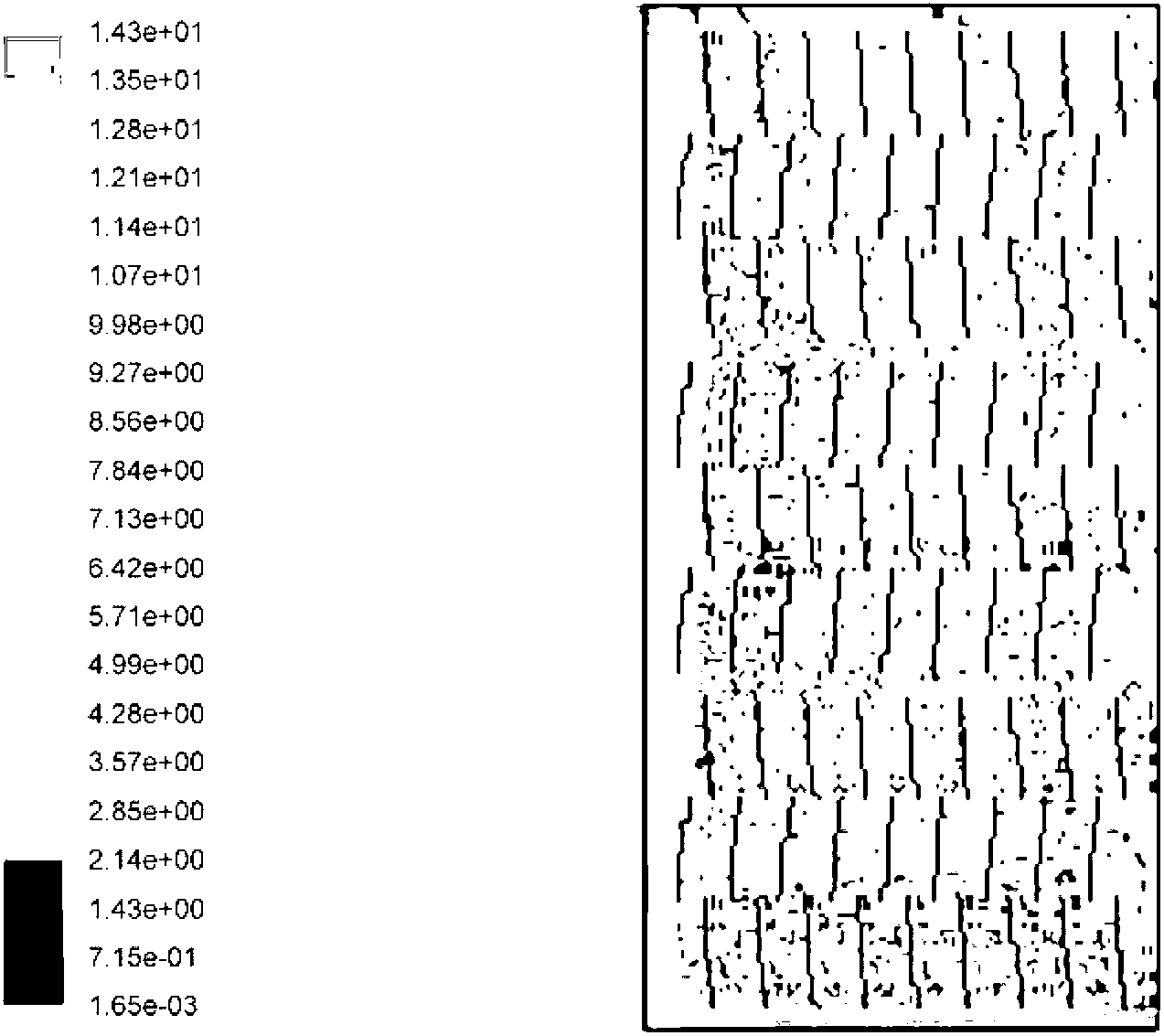

[0032] figure 1 is the schematic diagram of the appearance of the heat-absorbing plate core; figure 2 is a schematic diagram of the longitudinal section of the heat-absorbing plate core. Heat-absorbing core 1 core cavity 11 has a size of 2000mm×1000mm, and the two sides are inlet frame 112 and outlet frame 113 respectively. A total of 8 rows and 11 rows of flow-around fins 12 are arranged on the inner surface of the first side wall 111 of the core cavity 11 . The first row of flow-around fins 12 is parallel to the inlet frame 112 with a distance of 50 mm.

[0033] image 3 is the schematic diagram of the cross-section of the heat-absorbing plate core. The flow-around fins 12 each have a length of 100 mm to 200 mm, a thickness of 0.02 to 2 mm, and a height of 0.6 times the height of the inner cavity of the core cavity 11 .

[0034] In ea...

Embodiment 2

[0038]Process a kind of solar heat collector heat-absorbing plate core that the present invention provides, and it is no longer repeated with embodiment one, and its difference is:

[0039] In each row of flow-around fins 12, the rotation angles α of the second to fifth pieces of flow-around fins 12 increase progressively, which are 2°, 3°, 4°, and 5° respectively.

Embodiment 3

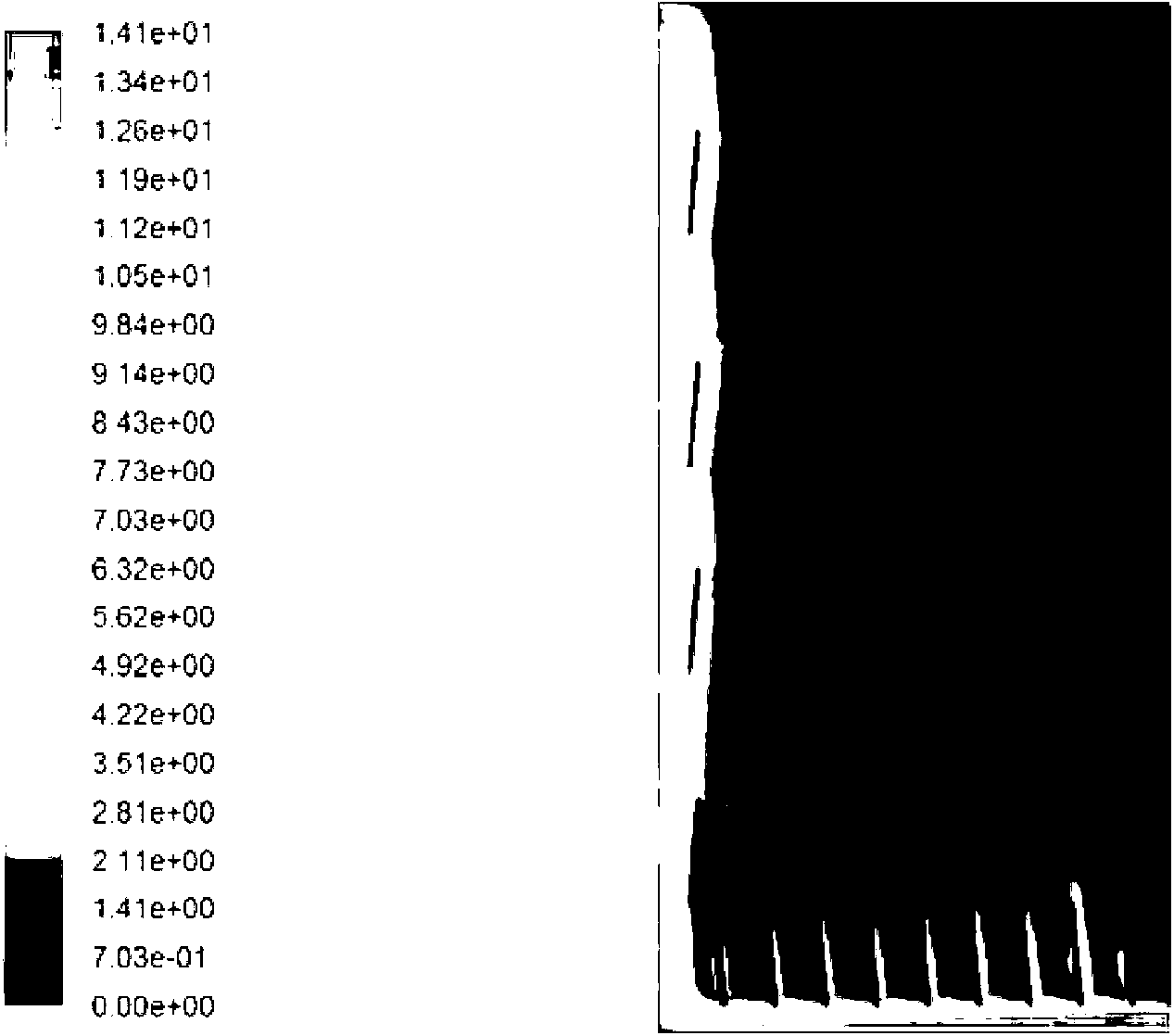

[0046] Such as Figure 6 , Figure 7 As shown, a solar collector is processed.

[0047] Figure 6 is a schematic diagram of the appearance of the solar collector; Figure 7 yes Figure 6 A-A cut-away diagram. The solar heat collector is a flat plate heat collector, the second side wall 115 of the heat-absorbing plate core 1 is opposite to the first side wall 111, and the second side wall 115 of the heat-absorbing plate core 1 is placed in the shell 5 upwards, and the shell 5 is open ; The outer surface of the second side wall 115 is coated with a selective coating to form the heat collecting plate 2; the glass cover plate 3 is covered on the shell 5 and sealed; the transparent cover plate 3 is adjacent to the heat collecting plate 2, and there is a heat insulating layer in between 4. The heat-absorbing plate core 1 is also connected with necessary pipelines; the collector inlet 6 passes through the shell 5 and opens at the lower part of the inlet frame 112, and the heat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com