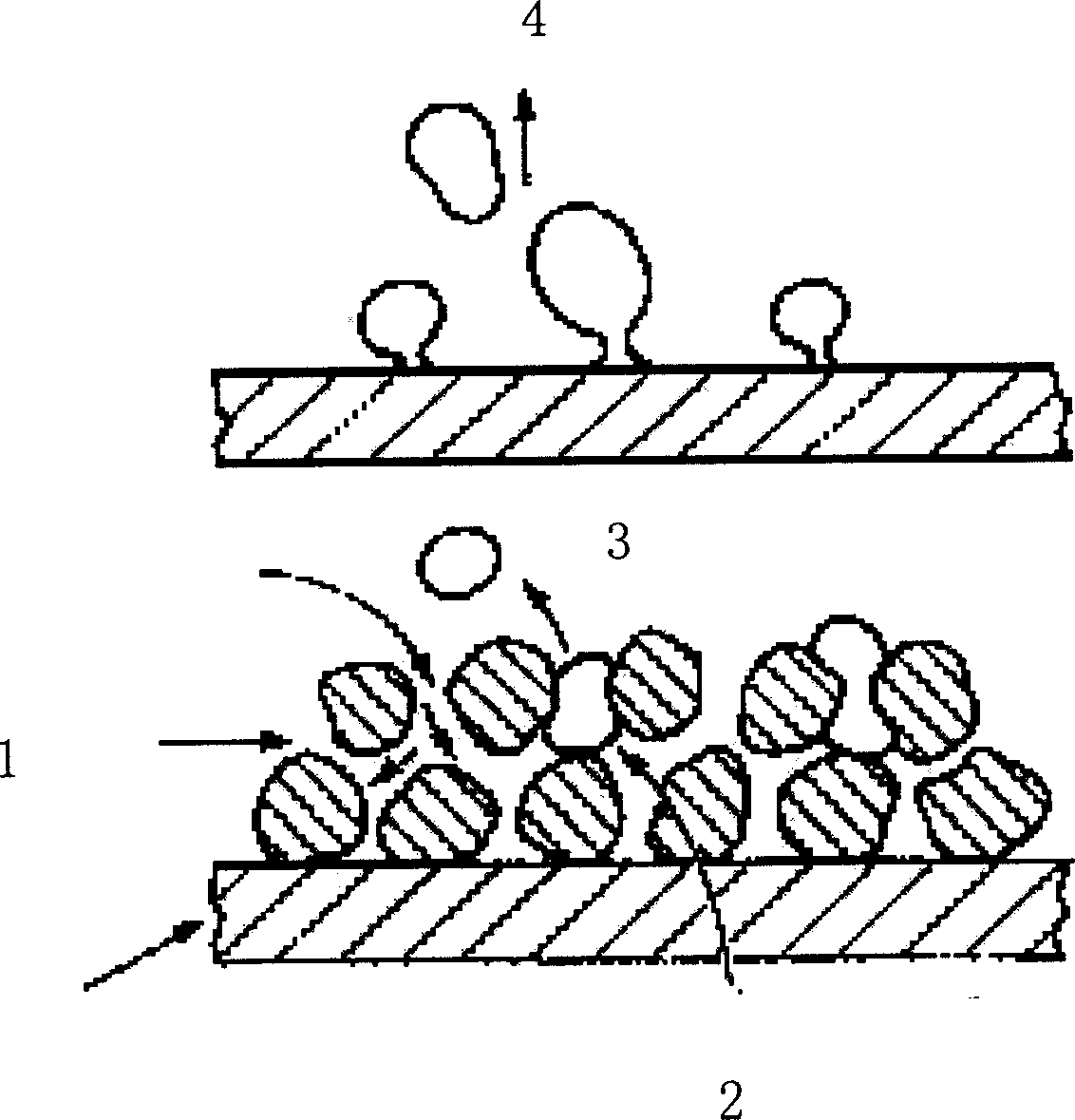

Column plate with porous surface

A technology of trays and porous layers, which is applied in the field of tray tower equipment, can solve problems such as porous surface compounding, and achieve the effects of uniform foam height, improved heat transfer, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Carbon steel is used as the material to process the sieve tray with a diameter of 100mm, the diameter of the sieve hole is 4mm, the opening rate is 10%, the width of the downcomer is 20mm, and the aluminum porous surface is processed on the surface of the carbon steel tray by spraying method. The layer thickness is 0.6 mm, the pore size is 100 microns, and the porosity is 30%.

[0034] In a depropanization rectification column with a diameter of 100 mm, the mass transfer performance of the sieve tray column of the present invention and a common sieve tray column was tested.

[0035] Adopt carbon three distillates raw material (molar composition is: propyne, propadiene: 2.57; Propylene: 70.36; Propane: 2.66; Butadiene: 11.92; Butene: 8.73; Butane: 0.25; Hexa-C8; 0.19; Benzene: 0.69; Toluene: 0.03) is raw material, test under the same plate number, opening ratio 10%, aperture 4mm, operating pressure, reflux ratio, test result is shown in Table 1.

[0036] project ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com