Process for preparation of hypoglycemic foods and formulations thereof

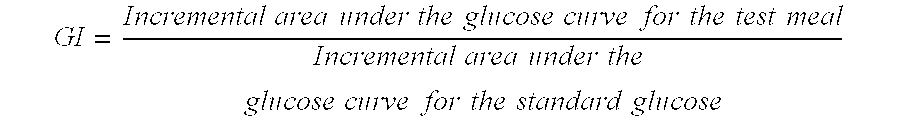

a technology of hypoglycemia and food, applied in the field of preparation of hypoglycemia foods and formulations thereof, can solve the problems of not providing authentic information about the nature and processing of ingredients, the blood glucose level is too high or low, and the proprietary diabetic foods are often not in the range normally recommended for diabetics, so as to improve the glucose and insulin variables, and the index of supplemental chromium is elevated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0079] Fifty kg wheat was sprayed with 1.5 L potable water, tempered for 10 min and scoured to 2.5% degree of decortication in a rice huller. The scoured wheat was toasted in a grain roaster at 70° C. till the grains changed to golden brown color. Two kg bengal gram dhal, 1.5 kg black gram dhal, 1.5 kg green gram dhal, 6 kg dehusked soy dhal and 3 kg fenugreek seeds, 1 kg pepper, 1 kg cumin seeds and 0.2 kg cinnamon, each toasted separately in a grain roaster by contact heat at about 80° C. till the development of characteristic desirable aroma from each of the ingredients. Subsequently, out of these toasted material, 30 kg wheat, 1.5 kg bengal gram dhal, 1 kg black gram dhal, 1 kg green gram dhal, 5 kg soy dhal, 2.5 kg fenugreek seeds, 0.75 kg pepper, 0.5 kg cumin seeds and 0.15 kg cinnamon were mixed well, and to that 1 kg dry Garcinia combogia rinds was added and the blend was pulverized in a plate mill to the meal of the particle less than 350 micron size.

[0080] To the pulveriz...

example 2

[0082] Fifty kg decorticated finger millet prepared following the process developed by CFTRI, Mysore (Malleshi, N. G., A process for preparation of decorticated finger millet. Indian Patent Application No. 69 / DEU2002, 2002), was toasted at 50° C. in a gram roaster. Two kg bengal gram dhal, 1.5 kg black gram dhal, 1.5 kg green gram dhal, 6 kg dehusked soy dhal and 3 kg fenugreek seeds, 1 kg pepper, 1 kg cumin seeds and 0.2 kg cinnamon, each toasted separately in a grain roaster by contact heat at about 80° C. till the characteristic desirable aroma from each of the ingredients developed.

[0083] Subsequently, out of these toasted material, 30 kg wheat, 1.5 kg bengal gram dhal, 1 kg black gram dhal, 1 kg green gram dhal, 5 kg soy dhal, 2.5 kg fenugreek seeds, 0.75 kg pepper, 0.5 kg cumin seeds and 0.15 kg cinnamon were mixed well, and to that 1 kg dry Garcinia combogia rinds was added and the blend was pulverized in a plate mill to the meal of the particle size of less than 350 micron....

example 3

[0085] Fifty kg each of wheat and millet based ready-to-cook formulations were prepared, as illustrated in examples 1 and 2, and the same were sprayed separately with a pre-determined amount of water to raise the moisture content to 18.0%, mixed well in a tumble mixer, equilibrated in closed container for about 24 hr and extrusion cooked in a single-screw extruder at 200 rpm and 140° C. barrel temperature at the feed rate of 100 kg / hr. The extrudates were cut at the exit point of the extruder mechanically to size similar to cheese roll and dried to 3% moisture level in a mechanical dryer. The expansion ratio, color, appearance, hardness and organoleptic qualities of the extruded material were assessed. The products with crisp texture and light brown color were readily accepted as ready-to-eat (RTE) food supplements, food adjuncts, snacks by diabetics and healthy population.

[0086] The color of the RTC and the RTE foods was measured in Hunterlab color measuring system where as the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com