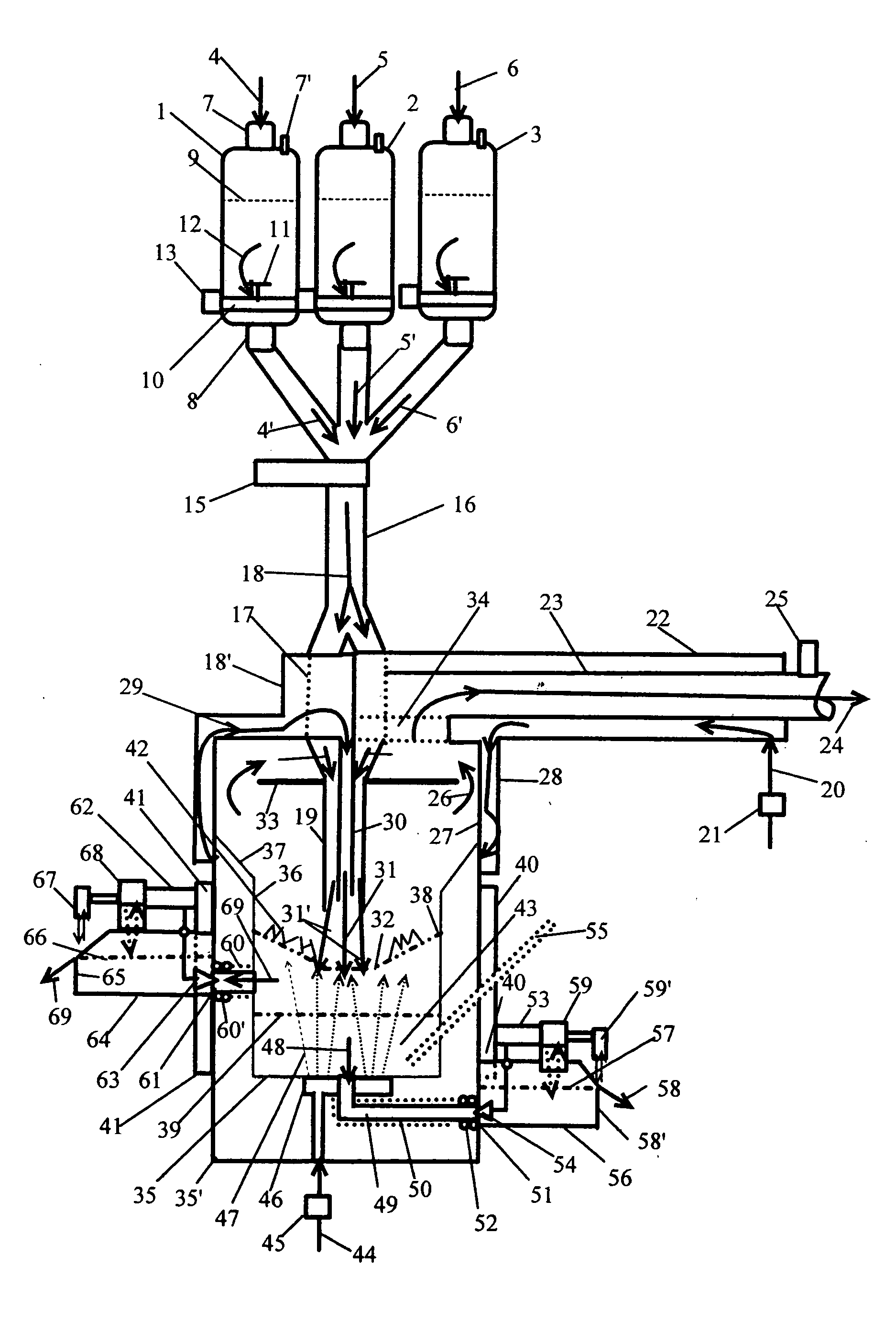

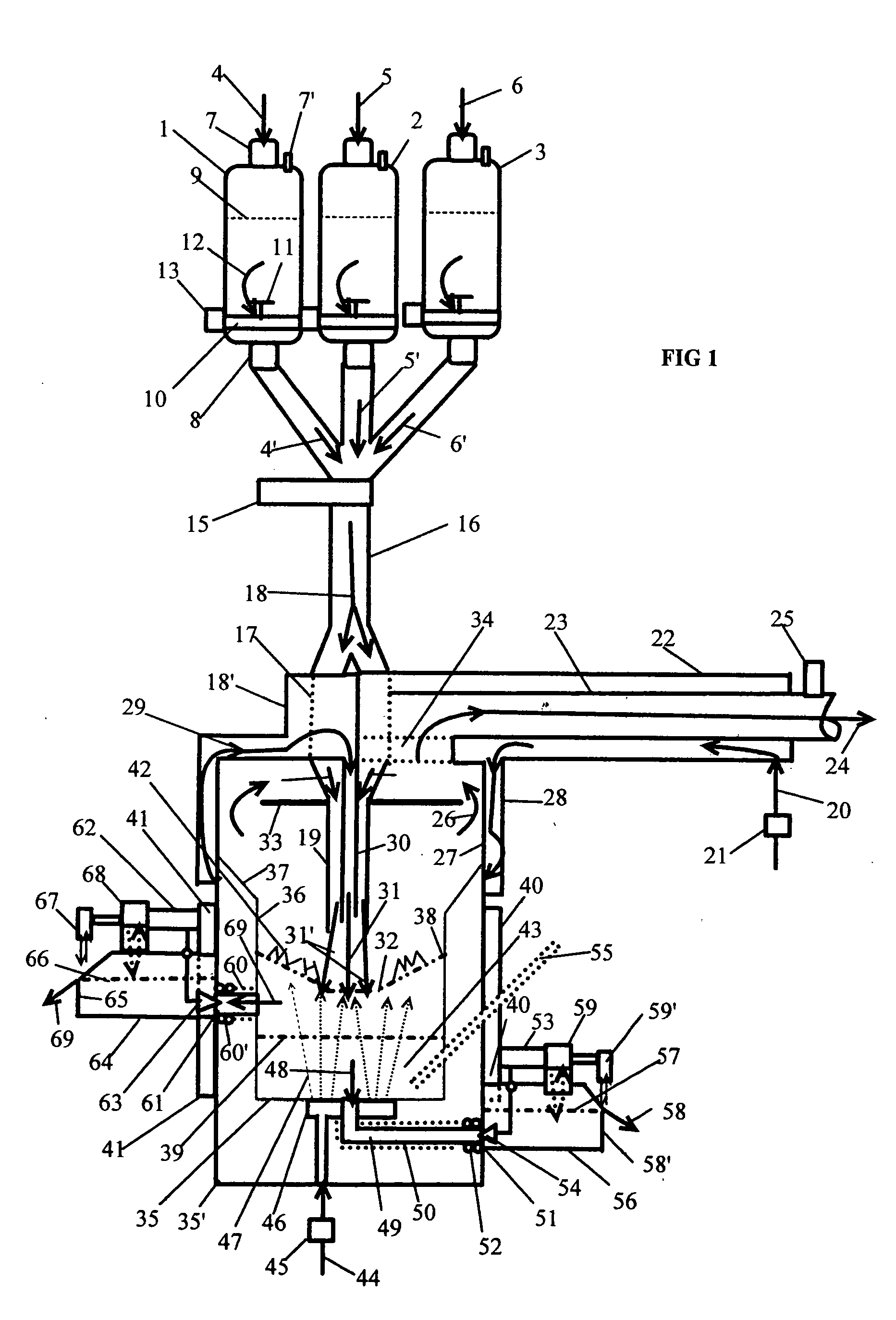

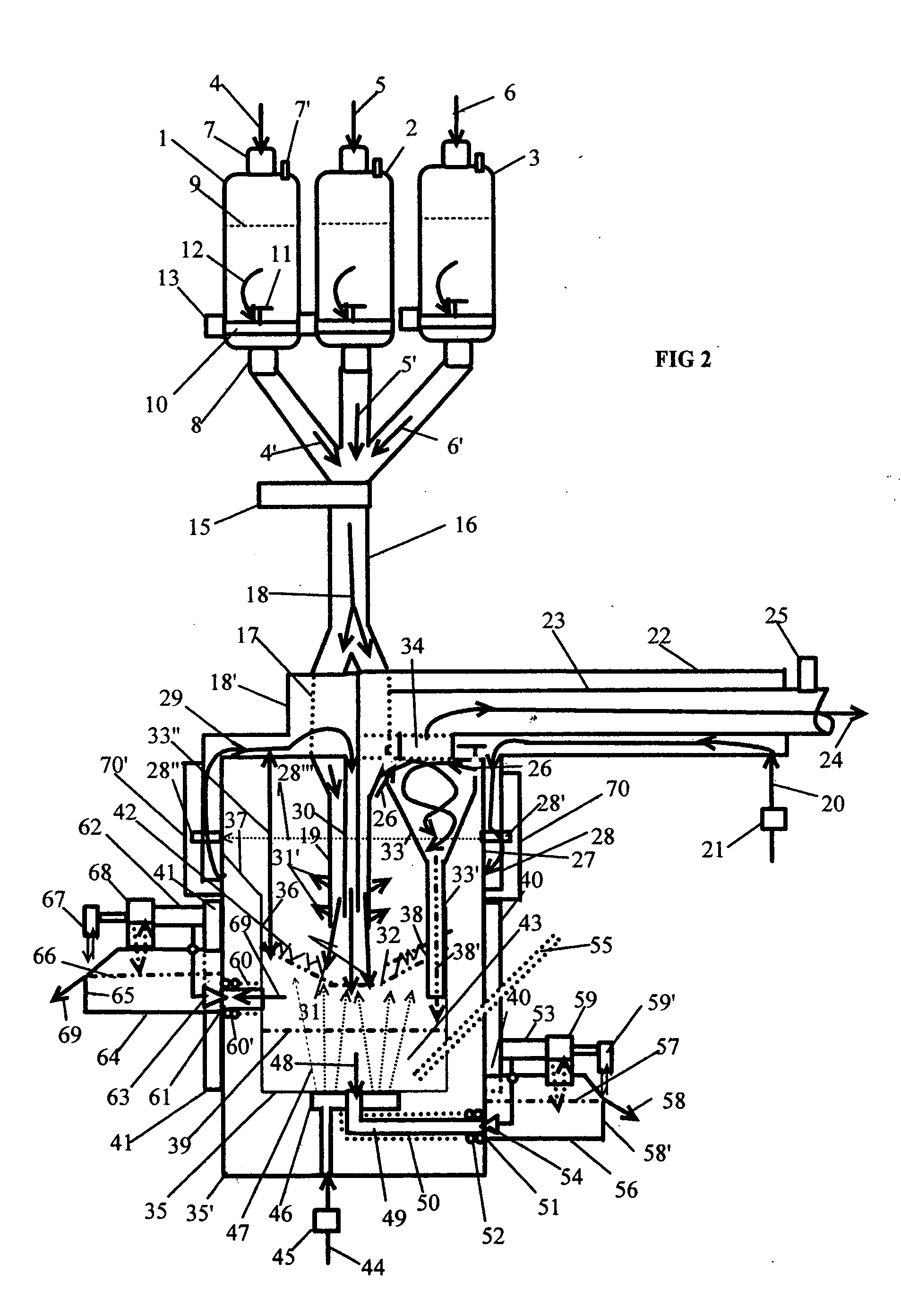

[0005] A direct and continuous controlled

smelting and low-grade steel making process or

coal or carbon gasification which involves blasting a mixture of pulverized ore (but not if just a gasifier),

coal, and a flux mixture(s) through a concentric

water cooled downward lance close into a molten

slag, with ore mix flowing between the outer cooled shell and inner core

air blast tube which expels air /

oxygen mixture at

high velocity onto the top of the molten

slag and steel

layers, and to make steel with air / oxygen blast under the molten layer from the base of the crucible distributed evenly through a fine bubbling diffuser mounted within the crucible floor so as to reduce carbon in the molten iron, means to separately meter ore mix ingredients from lock hoppers with bubble-tight valves to prevent gas from flowing back though the hoppers, and with in-line mixer before entering the concentric lance, and with CO2 / CO and temperature exit gas measurement instrument with exit gas concentric pipes allowing heating of inlet air / oxygen blast, including circulating such air / oxygen within the top

metal plenum of the furnace with inner shell made of high temperature steel alloys enabling achievement of 1200 F air / oxygen blast, and it has slag and low-grade steel outlet trough with above

laser spectrometer measurements to determine

chemical composition of both flows, and crucible vertical scanning nuclear gage of

molten steel, slag and fresh mix

layers to determine their vertical profile density and relative depths and placements, all this

instrumentation so as to combine and with suitable

computer control and optimizing algorithms and

software to properly control preheated ore mix feed rate and composition, levels of molten iron, air / oxygen blast rates, and to manipulate molten levels using either an actuated tap hole plug controller or

refrigerant to freeze a portion of the tap hole exit area or

eddy current inducing forces to slow down steel exit flow so as to provide reliable

backup methods of slag and steel flows so as to accurately maintain molten steel and slag

level set points within the crucible, all to produce a quality low-grade steel output with proper carbon,

sulfur and

potassium contents to the maximum practical extent so as to optimize steel making within one vessel in terms of quality and production requirements and to maximize the overall

cost effectiveness of process of

smelting and steel-making or gasification.

[0009] From the in-line mixer, a vertical

pipe with an enlarged section where the

water cooled lance section begins and where the hot air / oxygen enters through the outer cooled enlarged shell into the center

air blast tube, whereby such cooled lance enlargement is sufficient for all feed materials to flow at maximum rates easily passing by the narrow vertical rectangular tube penetrating into the lance

outer core on one side to feed the center circular round tube of the lance with

hot blast air / oxygen.

[0011] The upper shell of the furnace with insulated outer layer and high temperature steel

alloy inner layer allow the inner layer to finish heating the pre-heated air / oxygen blast to 1200 F, designed with sufficient inner surface area of the exposed upper furnace to achieve these final blast temperatures at full load steel flow given that such allow inner steel

alloy surfaces may be coated with

ceramic or other high temperature material to additionally protect the inner steel shell from

corrosion and provide sufficient insulating layer to prevent excessive temperature from melting or excessively lowering the strength of this steel

alloy. However, in any event, this upper furnace steel section would be supported above by a frame (not shown) surrounding the furnace on its sides as necessary.

[0014] Also to further assist in steel or molten flow control, the outer steel tap hole

ceramic pipe can be wrapped with

refrigeration coils through which

refrigerant at various temperatures and flow rates can be used to solidify steel to form smaller or larger openings tap hole openings to control the flow of molten steel out. Or, further molten steel and slag flow control reliability is achieved with an outer tap hole tapered plug usually used to control such molten steel flows with suitable

actuator, and readily available in the art. Or, the bottom hole can be arranged to use a tapered

plug valve for flow control.

[0015] These flows of slag and steel into a trough of sufficient volume and weir dam sufficiently higher than the tap hole to cover the tap hole such that the velocity of the flow does not overly agitate flow over the weir for weir vertical

level measurement purposes. A

radar or sound type

level measurement instrument locate above the weir can accurately determine the flow height in the weir notch to measure the volume of slag or steel flowing over the weirs.

[0028] Thus, it can be seen that this invention teaches a very advanced method of continuous steel making and / or gasification and uses the most modern combination of instruments and sensors to accomplish this, and it teaches a unique arrangement of equipment and process to avoid the need for

coke and expensive

recuperator to preheat air / oxygen blast to proper temperatures, and finally, optimization algorithms are suggested such that those skilled in the

computer programming arts in combination with steel process engineer experts in acid or basic steel making processes could enable such

software to take

advantage of with the instrument signals provide to

gain precise and accurate control over the process including ingredient mix ratios and all material flows to optimize steel outflow rates with quality for maximum

economic advantage with a minimum of labor input and

capital cost.

Login to View More

Login to View More