Electrode foil for electrolytic capacitor and method for manufacturing the same

a technology of electrolytic capacitors and electrolytic foils, which is applied in the direction of electrolytic capacitors, superimposed coating processes, coatings, etc., can solve the problems of difficult to uniformly mix dielectric fine particles into the electrolytic solution, and inability to increase electrostatic capacitance, etc., to achieve less defective dielectrics and high electrostatic capacitan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

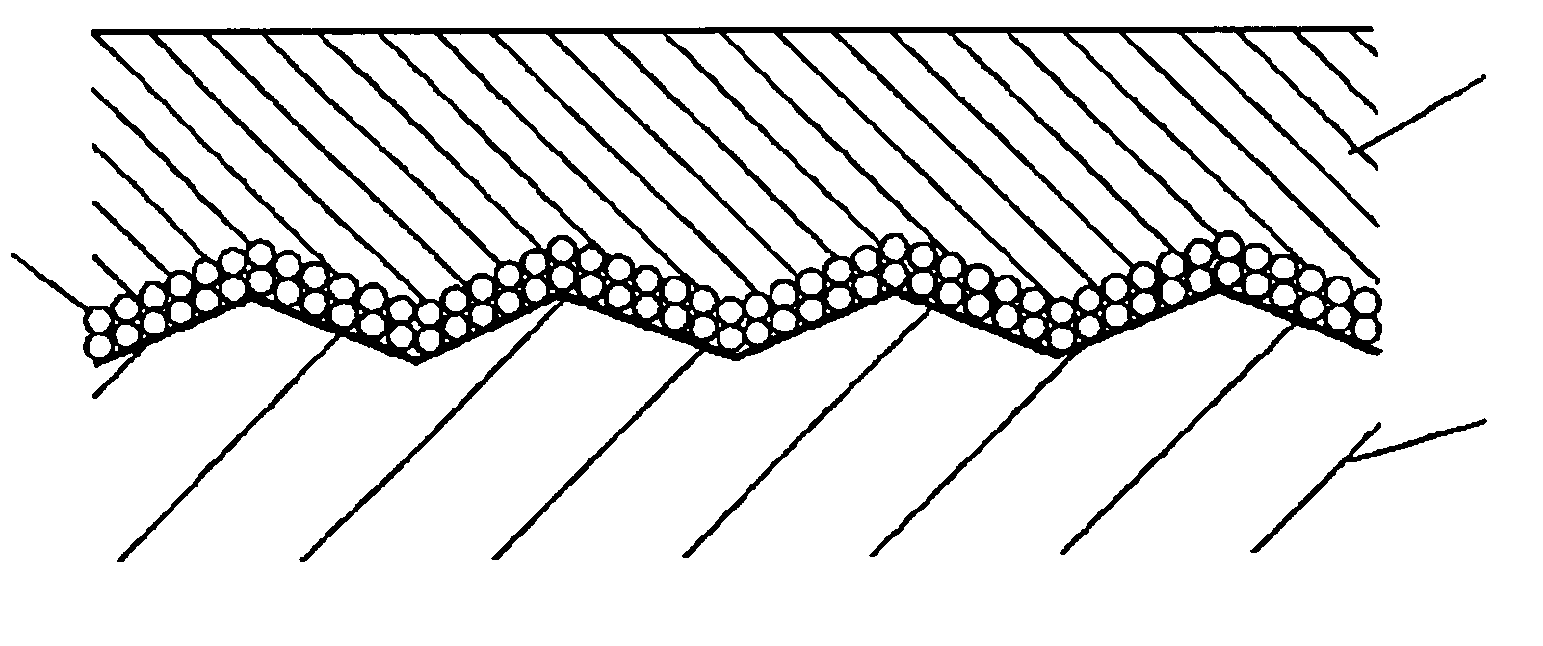

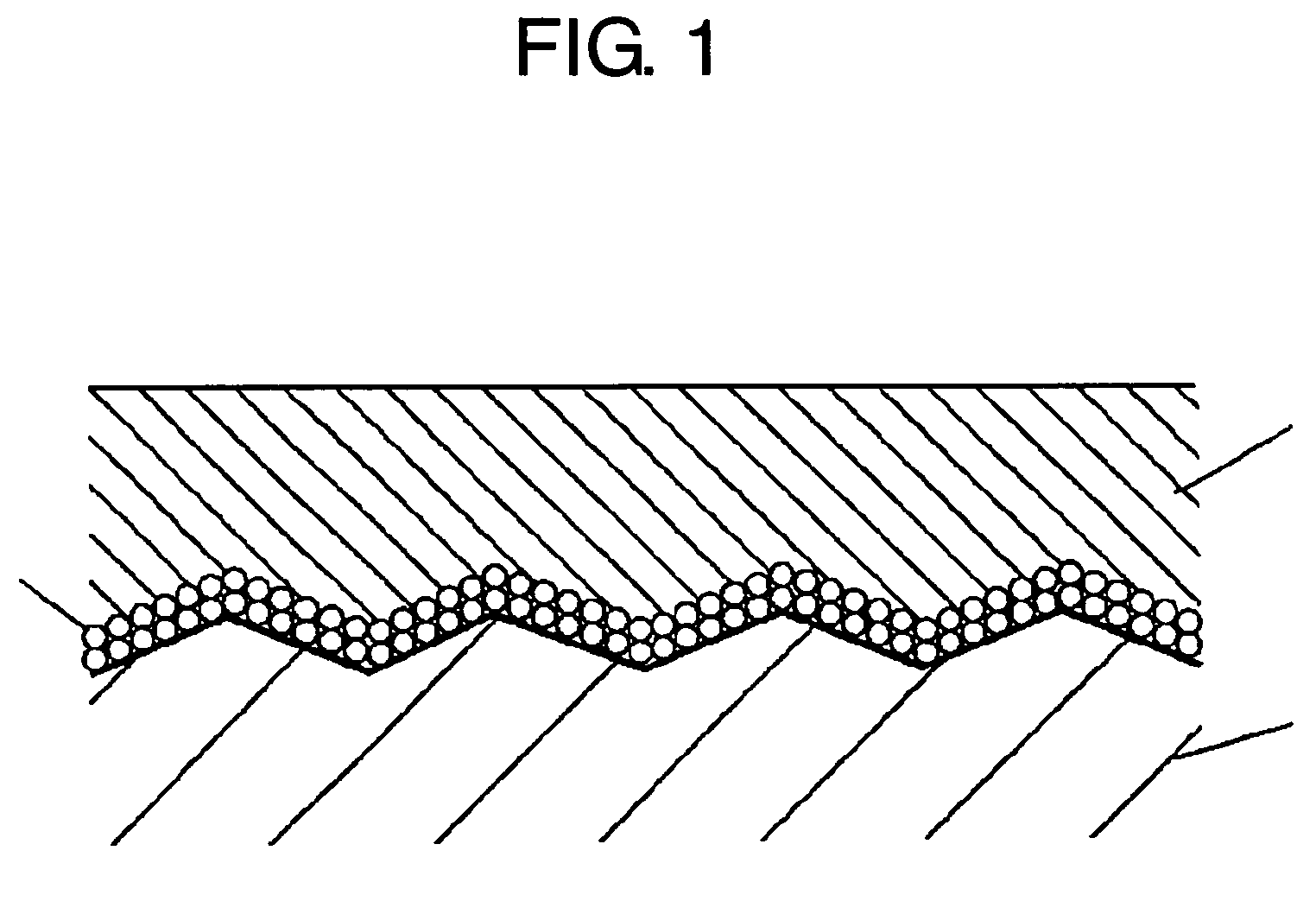

[0037] Firstly, pretreatment is carried out by dipping an aluminum foil having a thickness of 100 μm and a purity of 99.98% into an aqueous solution having a phosphoric acid concentration of 1.0 wt % at 90° C. for 60 seconds.

[0038] Then, this aluminum foil is subjected to etching treatment so as to roughen the surface rough.

[0039] The etching treatment was carried out by dipping the aluminum foil into an etching bath filled with electrolytic solution (aluminum concentration in the electrolytic solution was adjusted to 0.1 wt %) at 30° C. which included hydrochloric acid: 5 wt %, aluminum chloride: 2 wt %, sulfuric acid: 0.1 wt %, phosphoric acid: 0.5 wt %, and nitric acid: 0.2 wt %, and then applying alternating voltage (frequency of 35 Hz, for 100 seconds) to a pair of electrode plates.

[0040] After this etching treatment, the aluminum foil was dipped into 10% sulfuric acid aqueous solution to carry out dechlorination, dipped into an aqueous ammonia solution at pH 8 (temperature:...

example 2

[0043] An electrode foil for an electrolytic capacitor was produced in the same manner as Example 1 except that hydrogen ion concentration when the boehmite film was formed was adjusted to pH 9.0.

example 3

[0044] An electrode foil for an electrolytic capacitor was produced in the same manner as Example 1 except that hydrogen ion concentration when the boehmite film was formed was adjusted to pH 10.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com