Deformable mirror method including bimorph flexures

a deformation mirror and bimorph technology, applied in the field of long stroke mems deformation mirror arrays, can solve the problems of limited stroke of available dms, widespread adoption of ao, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

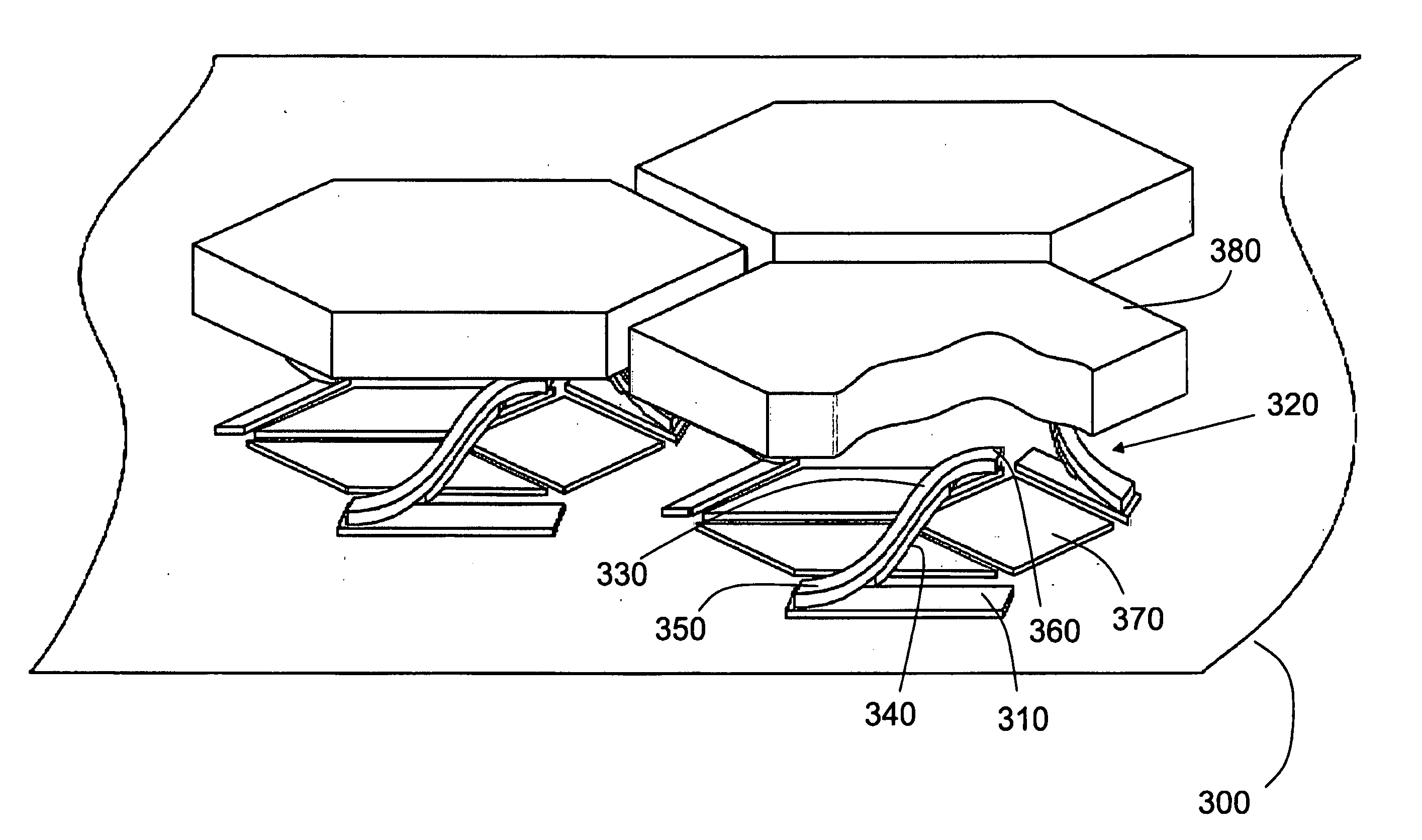

first embodiment

[0052] The following is a general overview of the process of the current invention for fabricating the DM. The process involves separately fabricating the MEMS structure and the addressing and sensing circuits on two separate wafers, then assembling them together as shown in FIGS. 4A and 4B. FIG. 4A is a process flow diagram and FIG. 4B illustrates the corresponding structure at each step. As shown at step 400, each mirror segment 380 is fabricated by reactive ion etching (RIE) the top single crystal silicon “device” region of a bonded silicon-on-insulator wafer (BSOI). At step 405, the wafer is then coated with a sacrificial layer to fill the trenches left by the previous etch, provide a temporary support for various mechanical structures of the DM, and optionally to act as a dopant source for undoped polysilicon regions. This sacrificial layer might typically be phosphorus-doped silicate glass deposited by low pressure chemical vapor deposition (LPCVD). Alternatively, in cases whe...

third embodiment

[0070] the DM comprises a substrate 900, which may be a silicon wafer. On top of the substrate 900 are formed a number of control electrodes 960 that are electrically isolated from one another and electrically connected to conductive traces (not shown in FIG. 9) that may either be embedded in the substrate 900 or attached to the surface of the substrate 900. These traces electrically connect the control electrodes 960 directly to bond pads (not shown in FIG. 9) that may be disposed around the perimeter of the DM chip. The control electrodes 960 are arranged in groups of three and are rhombic in shape, so that the footprint of each group is essentially hexagonal.

[0071] Disposed around each group of three control electrodes 960, are three conductive ground pads 910, fabricated from the same material as the control electrodes 960. The ground pads 910 are electrically isolated from the control electrodes 960 and electrically connected to a ground plane embedded in the substrate 900. Att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com