Stainless steel for use under circumstance where organic acid and saline are present

a technology of organic acid and saline, which is applied in the field of stainless steel, can solve the problems of accelerating the corrosion of stainless steel by organic acid, and achieve the effect of improving the corrosion resistance of organic acid and a large amount of common sal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

As the first step, the inventors of the present invention investigated the difference between the environment in the manufacturing process of soy sauce which has a fermentation process and organic acid such as amino acid or lactic acid generate during said fermentation process and the environment in which such organic acids are not existing. In the experiments, commercial SUS316L of 2 mm in thickness was used as the specimen and two pieces which were cut to 20 mm×25 mm×2 mm and 60 mm×20 mm×2 mm were piled up and spot resistance welding was done at 4 points, thus the test piece with crevice for corrosion test was prepared. Although the ordinary soy sauce contains various kinds of organic acid, for the purpose to simplify the system, 4 kinds of test solution mentioned below were prepared. Namely, glutamic acid and asparagic acid, which are a kind of amino acid and are the typical organic acid generates at the fermentation process and lactic acid, citric acid and acetic acid which are...

experiment 2

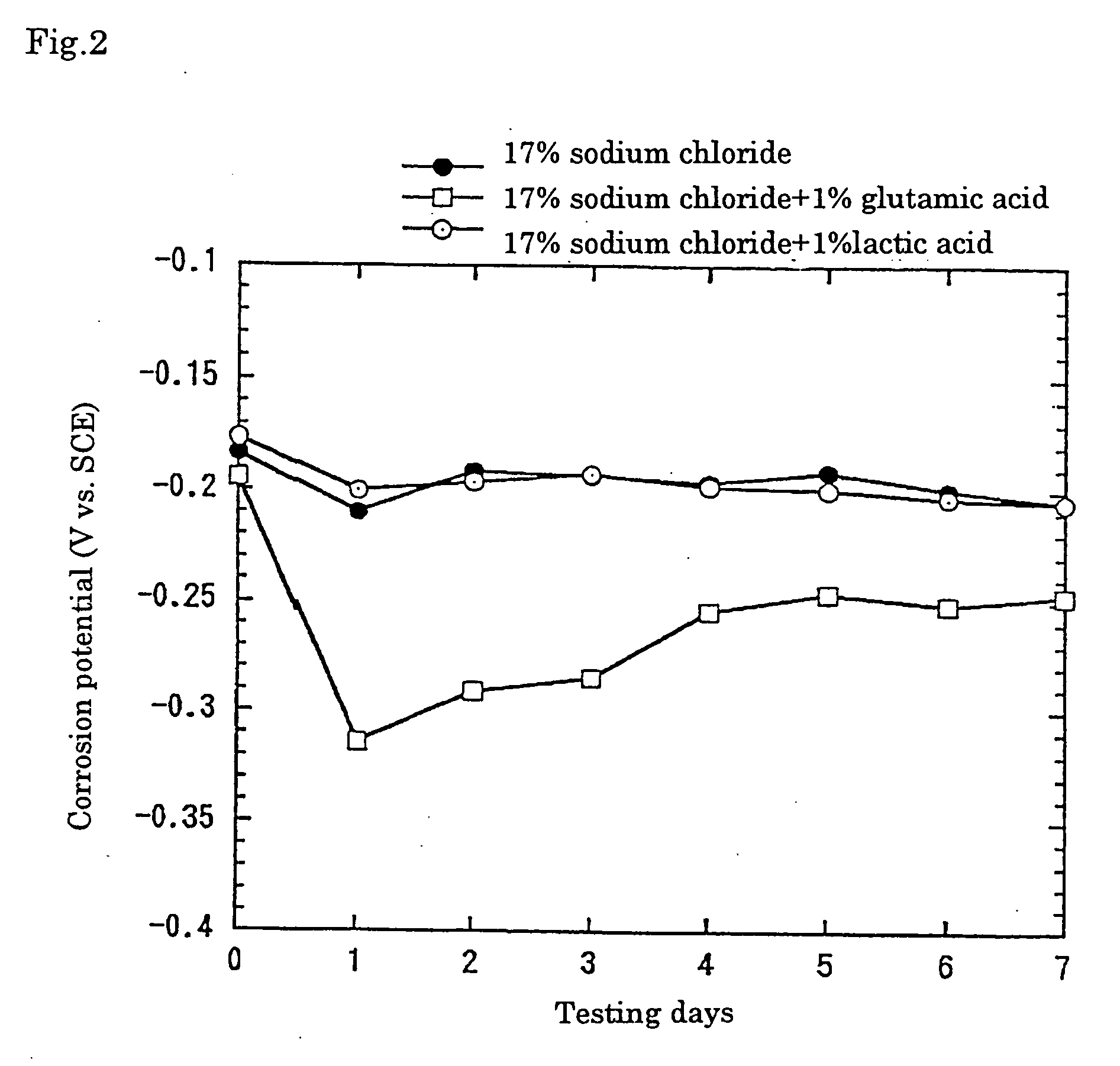

For the purpose to investigate the mechanism of the enhancement of corrosion by organic acid, the inventors of the present invention carried out the surface analysis of the SUS316L test piece which was dipped into high concentrated sodium chloride solution containing organic acid for long time and electrochemical measurement in said solution. Specifically, following 3 kinds of test solution were prepared and maintained at 35° C. 2-{circle over (1)}: 17% sodium chloride 2-{circle over (2)}: 17% sodium chloride+1% glutamic acid 2-{circle over (3)}: 17% sodium chloride+1% lactic acid

SUS316L flat plate test pieces polished with #400 emery grinding paper under wet condition were dipped into the above mentioned test solutions for 1 week, and the structural feature of the surface passive film was analyzed by Auger electron spectroscopic analyzer (hereinafter shortened to AES). And the surfaces of same test pieces were observed by a scanning electron microscope (hereinafter shortened ...

experiment 3

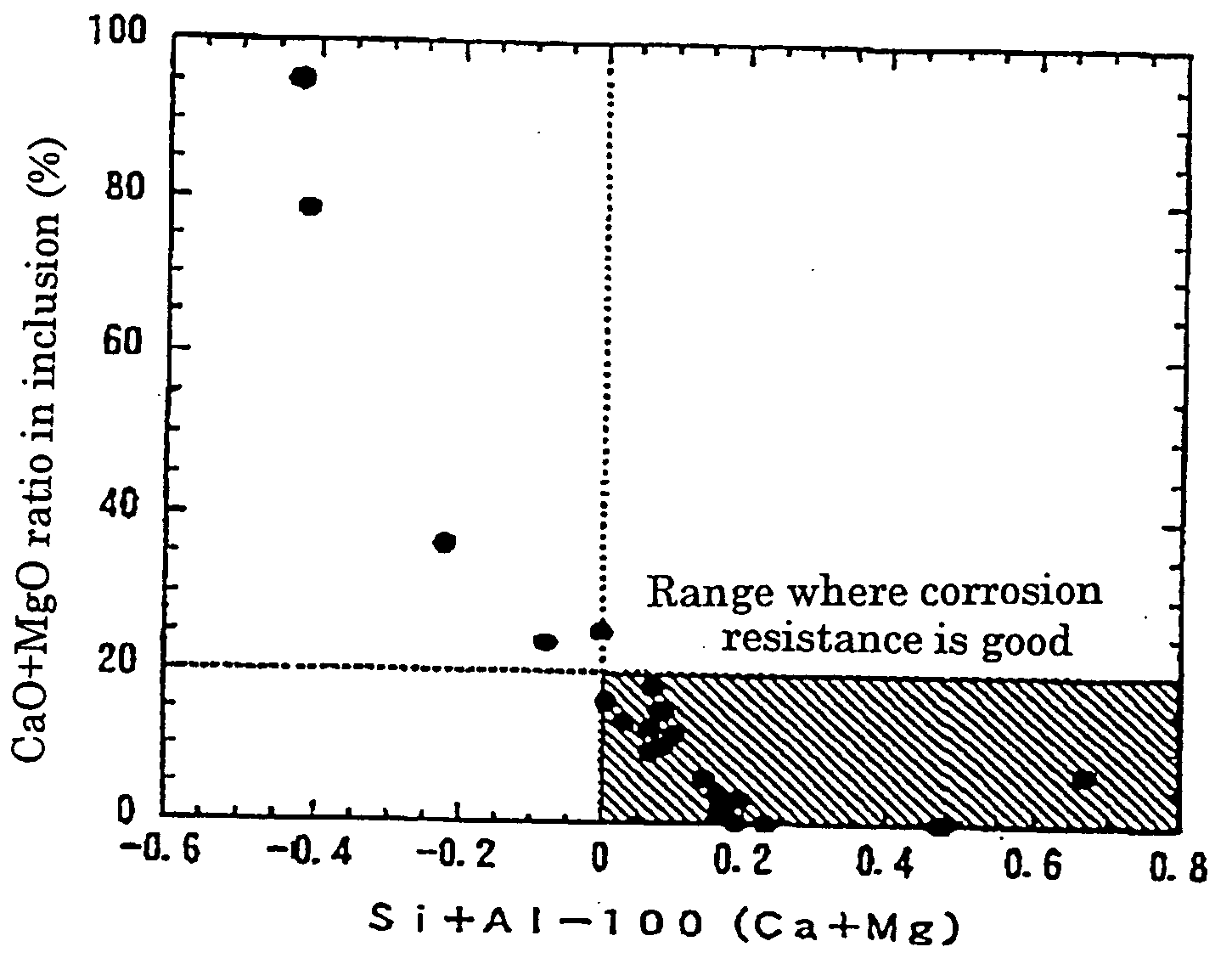

The peculiarity of the environment of soy sauce manufacturing plant containing common salt in high concentration in which organic acid exists, the deterioration of the surface passive film by organic acid and the mechanism to enhance the corrosion by selective dissolution of the inclusions mainly composed of CaO or MgO are recited above. As the next step, the inventors of the present invention carried out the following experiment aiming to find out the proper composition of the stainless steel which exhibits good corrosion resistance in such a particular environment. Stainless steel, whose chemical composition is in the range mentioned below, was produced by an induction furnace so as the weight ratio of CaO+MgO in oxide inclusions in steel to be variously changed, and ingots were obtained.

C: 0.008-0.035 wt %, Si: 0.02-0.24 wt %, Mn: 0.13-0.92 wt %, P: 0.017-0.034 wt %, S: 0.001-0.003 wt %, Ni: 6.44-34.83 wt %, Cr: 16.51-25.12 wt %, Mo: 2.06-7.47 wt %, Cu: 0.01-0.86 wt %, W: 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com