GaN substrate including wide low - defect region for use in semiconductor element

a semiconductor element and substrate technology, applied in semiconductor lasers, crystal growth processes, semiconductor/solid-state device details, etc., can solve the problems of high density of semiconductor laser devices, inability to reliably produce semiconductor laser devices produced by processes, and inability to reliably produce semiconductor laser devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0048] First Embodiment

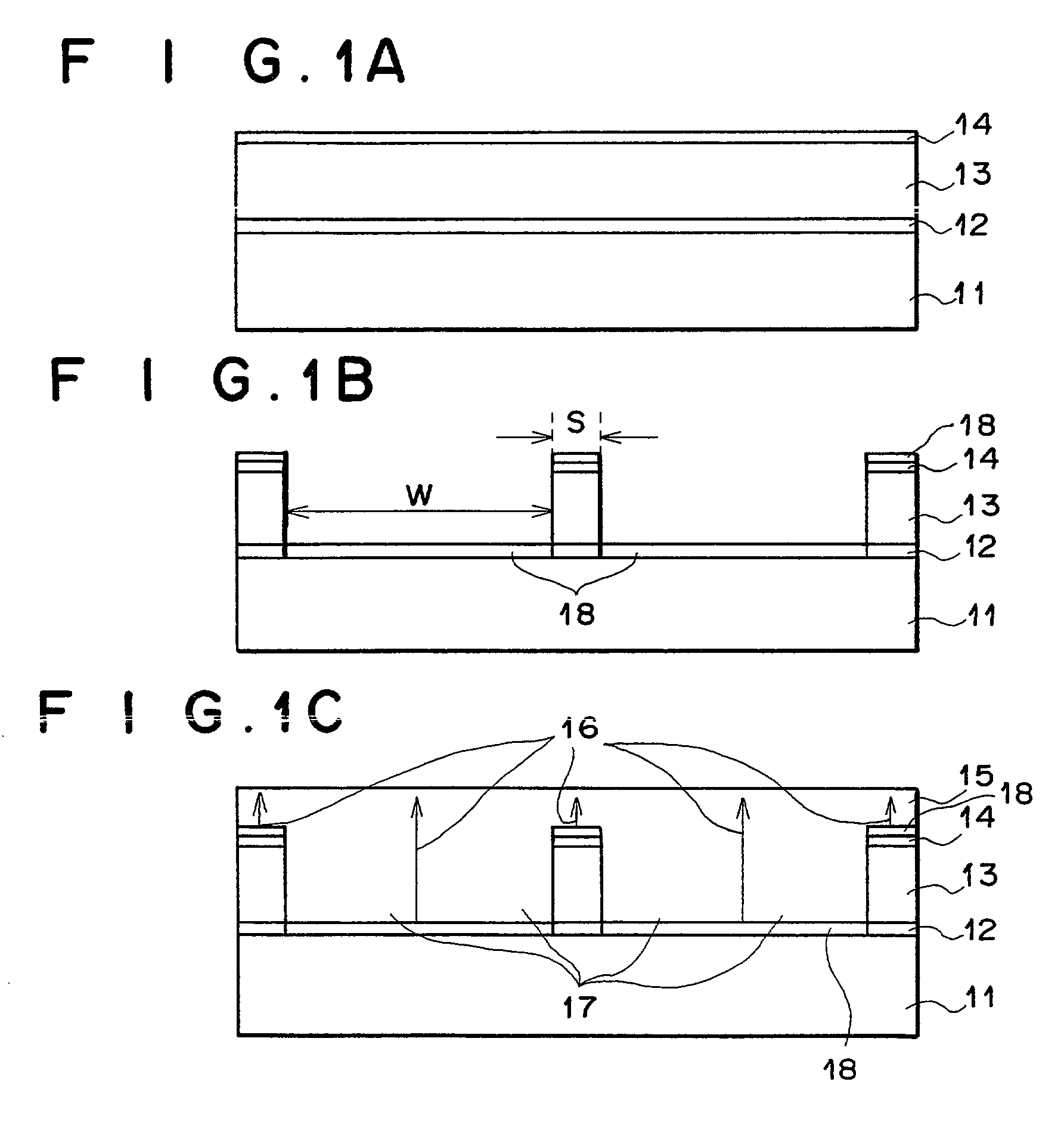

[0049] FIGS. 1A to 1C are cross-sectional views of representative stages of a process for producing a semiconductor substrate in the first embodiment of the present invention.

[0050] As illustrated in FIG. 1A, a GaN buffer layer 12 having a thickness of about 20 nm is formed on a (0001) face of a sapphire substrate 11 at a temperature of 500.degree. C. by the normal pressure MOCVD (metal organic chemical vapor deposition) technique using trimethyl gallium (TMG) and ammonia as raw materials. Then, a GaN layer 13 having thickness of about 5 micrometers is formed on the GaN buffer layer 12 at a temperature of 1,050.degree. C. Next, a SiO.sub.2 layer 14 is formed on the GaN layer 13, and a resist film (not shown) is formed on the SiO.sub.2 layer 14. Then, stripe areas of the SiO.sub.2 layer 14 oriented in the direction are removed by the conventional photolithography, so as to form a line-and-space pattern comprised of SiO.sub.2 stripes being spaced with intervals...

second embodiment

[0055] Second Embodiment

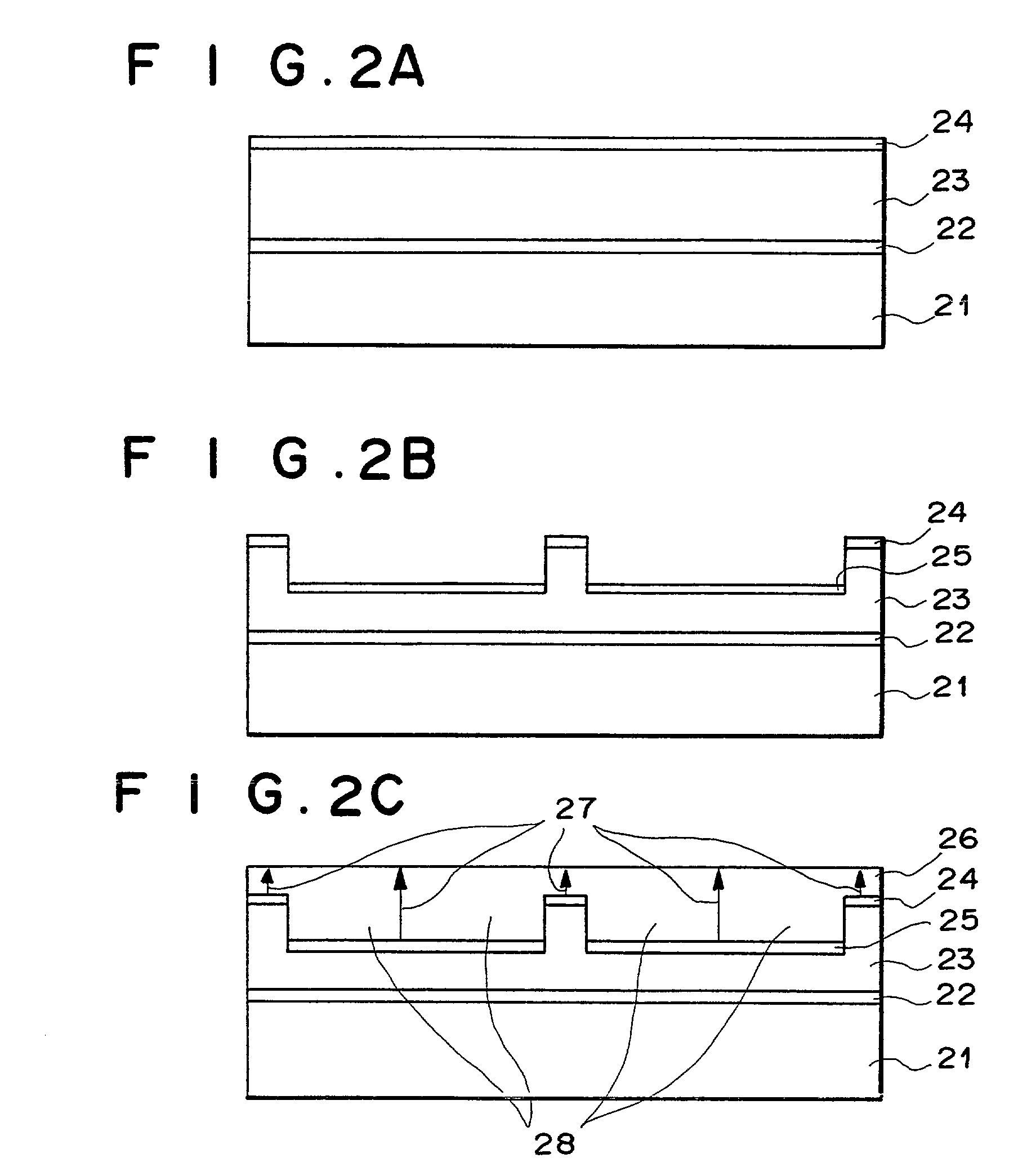

[0056] FIGS. 2A to 2C are cross-sectional views of representative stages of a process for producing a semiconductor substrate in the second embodiment of the present invention.

[0057] As illustrated in FIG. 2A, a GaN buffer layer 22 having a thickness of about 20 nm is formed on a (0001) face of a sapphire substrate 21 at a temperature of 500.degree. C. by the normal pressure MOCVD technique using trimethyl gallium (TMG) and ammonia as raw materials. Then, a GaN layer 23 having thickness of about 5 micrometers is formed on the GaN buffer layer 22 at a temperature of 1,050.degree. C. Next, a SiN.sub.x film 24 is formed on the GaN layer 23, and a resist film (not shown) is formed on the SiN.sub.x film 24. Then, stripe areas of the SiN.sub.x film 24 oriented in the direction are removed by the conventional photolithography, so as to form a line-and-space pattern comprised of SiN.sub.x stripes being spaced with intervals (W) of 25 micrometers and each having a wi...

third embodiment

[0060] Third Embodiment

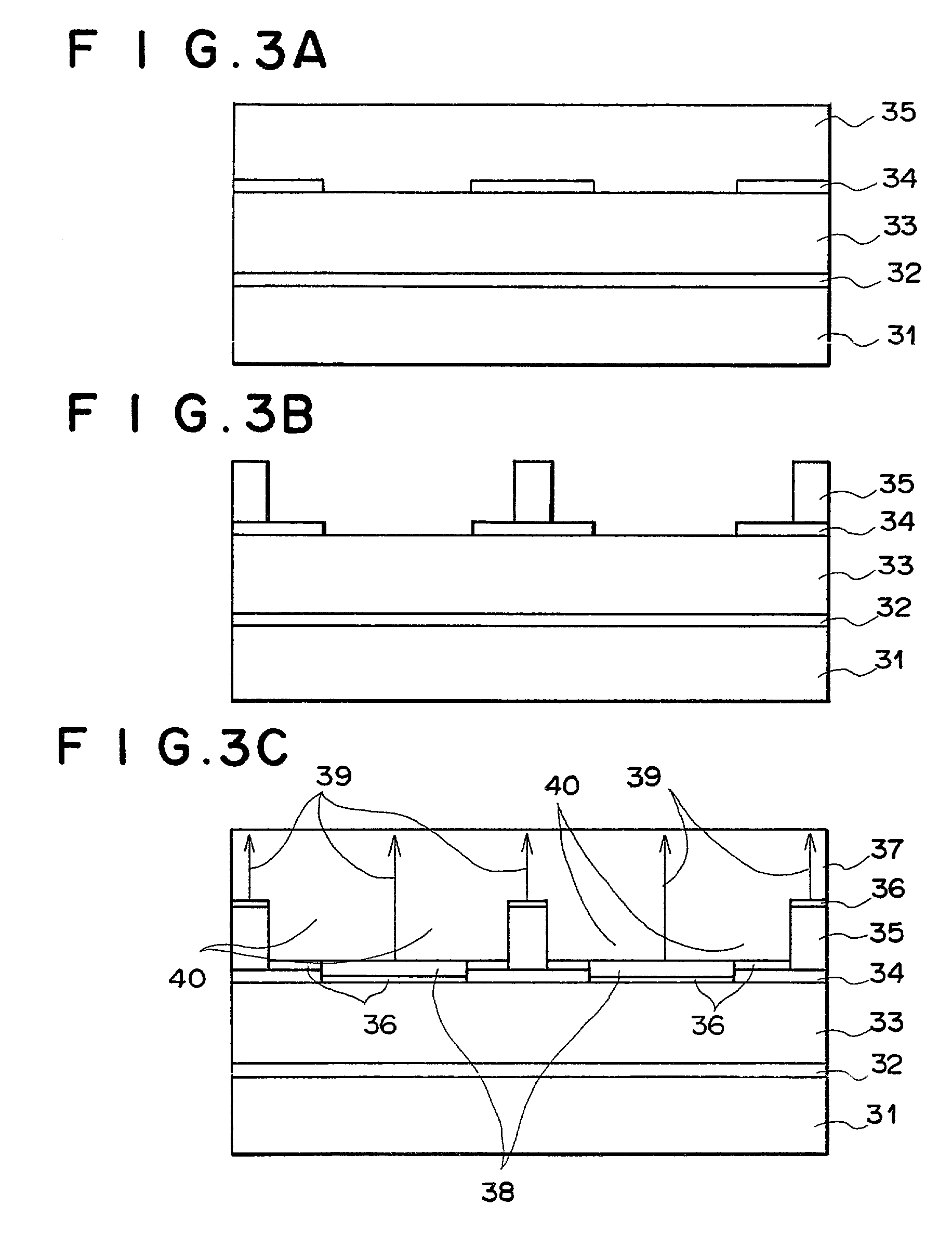

[0061] FIGS. 3A to 3C are cross-sectional views of representative stages of a process for producing a semiconductor substrate in the third embodiment of the present invention.

[0062] As illustrated in FIG. 3A, a low-temperature GaN buffer layer 32 having a thickness of about 20 nm is formed on a sapphire substrate 31 at a temperature of 550.degree. C. by the normal pressure MOCVD technique. Then, a GaN layer 33 is formed on the low-temperature GaN buffer layer 32 at a temperature of 1,050.degree. C. Next, a SiN.sub.x film 34 (having a thickness of about 0.5 micrometers) is formed on the GaN layer 33 by the plasma CVD technique, and a resist film (not shown) is formed on the SiN.sub.x film 34. Then, stripe areas of the SiN.sub.x film 34 oriented in the direction are removed by the conventional photolithography, so as to leave SiN.sub.x stripes 34 being spaced with intervals (W) of 20 micrometers and each having a width of 15 micrometers. Thereafter, a GaN layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| output power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com