Plasma treatment method and plasma etching method

A plasma and processing method technology, applied in the field of plasma etching, which can solve the problems of high global warming potential, difficult to obtain high verticality of etching profile, high etching rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

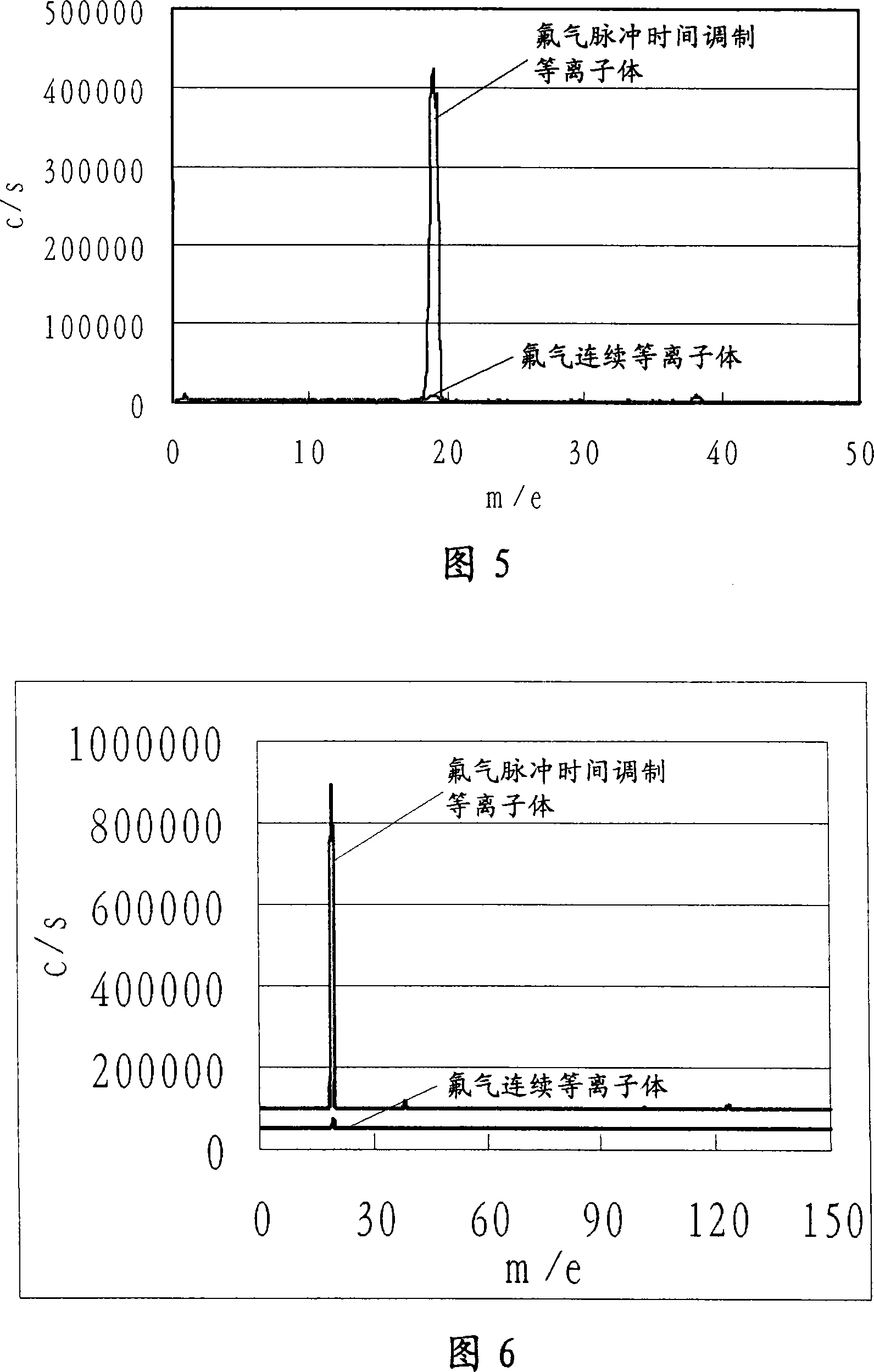

[0174] From fluorine gas (F 2 ) to generate continuous plasma, pulse time modulated plasma and neutral beam, then use QMS (quadruple mass spectrometer), microwave interferometer, emission spectrometer, Faraday cage and calorimeter to analyze the generated continuous plasma, pulse time Modulation of plasma and neutral beams.

[0175] First, the structure of the plasma and neutral beam analysis device shown in Fig. 4 is as follows. In the plasma and neutral beam analysis device shown in FIG. 4 , the plasma generation chamber 42 made of quartz is the same as that of the plasma generation and substrate processing chamber 2 made of quartz in the pulse time modulation plasma generation device shown in FIG. 1 . The structure is the same. The plasma generation chamber 42 has an inlet for feeding process gas 41, and an antenna 43 for generating inductively coupled plasma is wound around the periphery of the plasma generation chamber in a coil shape, and the antenna 43 and the antenna...

example 2

[0210] Through fluorine gas (F 2 ) pulse time modulated plasma to etch the substrate, measure the etching rate of silicon (Si) and observe the etching form.

[0211]

[0212] Using the pulse time modulation plasma generation device shown in Figure 2, the same 100 volume % fluorine gas (F 2 ) as processing gas 61 is introduced into the plasma generation and substrate processing chamber 62 at a rate of 30 mL / min, and an RF bias (1 kW) with a discharge frequency of 13.56 MHz is applied to the antenna 63 from a high-frequency power supply 64 to generate continuous plasma65.

[0213] An RF bias of 1 MHz was applied to a carbon electrode for accelerating ions 68 with a 50 W output of a power supply for applying a voltage 69 . By applying an RF bias to the electrode made of carbon for accelerating the ions 68 in this manner, cations and anions generated in the plasma 65 are accelerated in a direction almost perpendicular to the substrate holding base 70 and radiated onto the subs...

example 3

[0221] From fluorine gas (F 2 ) pulse time-modulates the plasma to selectively capture and neutralize negative ions to generate a neutral beam. Etching of the substrate is performed by neutral beam. To examine the composition of the neutral beam, measurements were made on polysilicon (poly-Si) and SiO using electrodes that acquired beams with different F group adhesion coefficients. 2 etch rate, and also observed the etched form of polysilicon.

[0222]

[0223] Using the neutral beam generating device shown in Figure 3, the same 100% by volume fluorine gas (F 2 ) is introduced into the plasma generation chamber 22 at a rate of 30 mL / min as the processing gas 21, and a 1 kW RF bias with a discharge frequency of 13.56 MHz (at the turn-on time) is applied to the antenna 23 from a high-frequency power supply 24 in a pulsed state, To generate pulse time modulated plasma. In this step, the on time / off time in the pulse time modulation is 50 microseconds / 50 microseconds.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com