Composite material capable of releasing negative ion produced from polythene / opal, and preparation technique

A composite material and opal technology, which is applied in the field of polyethylene/opal composite materials that release negative ions and their preparation technology, and can solve the problems of imbalance of positive and negative ions, destruction of air cleanliness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

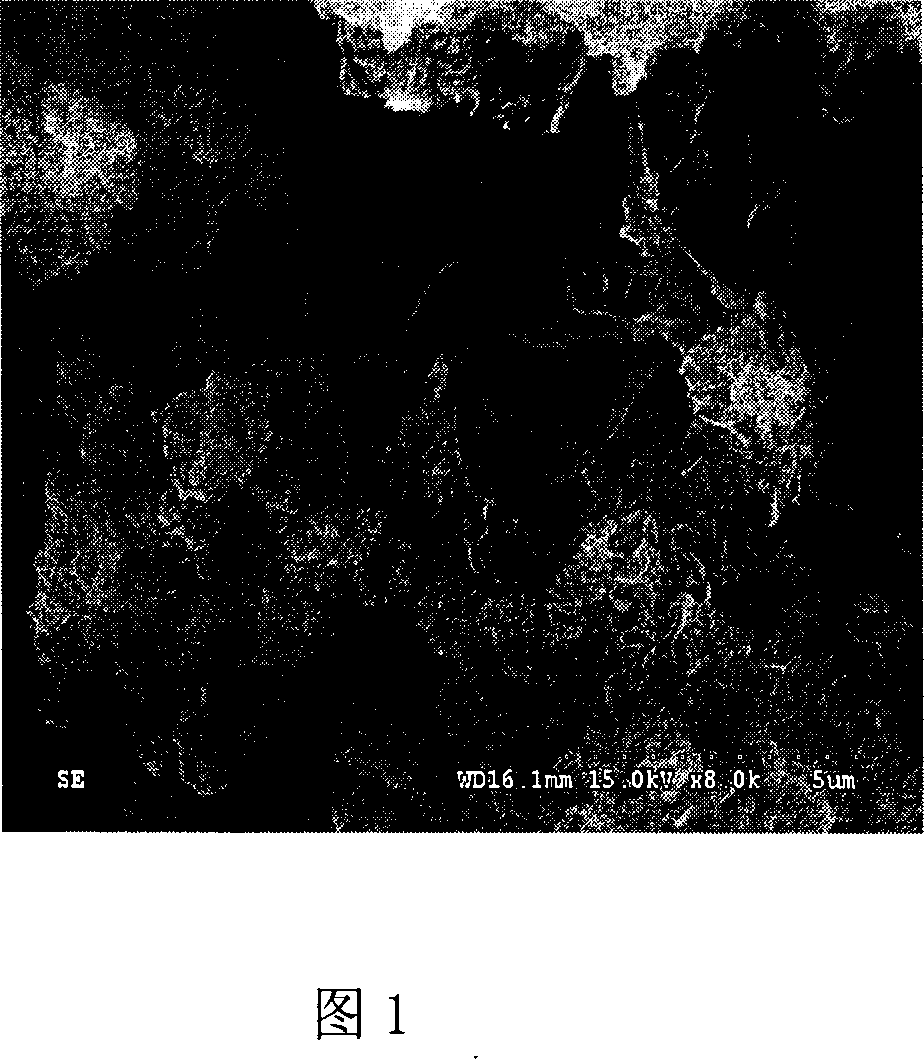

Image

Examples

Embodiment 1

[0017] The reaction pressure is 0.1MPa, the reaction temperature is 70°C, the reaction solvent is 50ml of toluene, the content of the supported catalyst (OC) is 1 μmol, the content of the co-catalyst MAO is 1000 μmol, and the polymerization reaction is 30 minutes to obtain a polyethylene / opal composite material with a reactivity of 3.50× 10 6 g(mol Zr h) -1 , with a melting point of 133.3°C and a viscosity-average molecular weight of 2.83×10 4 g / mol, in which the content of opal is 3.2%, the number of negative ions released by the composite material is 2240 / cm 3 above.

Embodiment 2

[0019] The reaction pressure is 0.1MPa, the reaction temperature is 70°C, the reaction solvent is 50ml toluene, the supported catalyst (OC) content is 1 μmol, the co-catalyst MAO content is 2000 μmol, and the polymerization reaction is 30min to obtain a polyethylene / opal composite material with a reactivity of 8.98× 10 6 g(mol Zr h) -1 , with a melting point of 133.2°C and a viscosity-average molecular weight of 2.46×10 4 g / mol, in which the opal content is 1.3%, the number of negative ions released by the composite material is 3600 / cm 3 above.

Embodiment 3

[0021] The reaction pressure is 0.1MPa, the reaction temperature is 70°C, the reaction solvent is 50ml toluene, the supported catalyst (OC) content is 1 μmol, the co-catalyst MAO content is 3000 μmol, and the polymerization reaction is 30min to obtain a polyethylene / opal composite material with a reactivity of 10.26× 10 6 g(mol Zr h) -1 , with a melting point of 133.0°C and a viscosity-average molecular weight of 2.32×10 4 g / mol, where the opal content is 1.1%, the number of negative ions released by the composite material is 2810 / cm 3 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com