Disinfectant composition with function of deodorization and bleaching effects and its prepn. method

A technology for compositions and crystalline compounds, applied in the fields of botanical equipment and methods, deodorization, disinfection, etc., can solve the problems of explosion, inconvenient use, poor instant effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

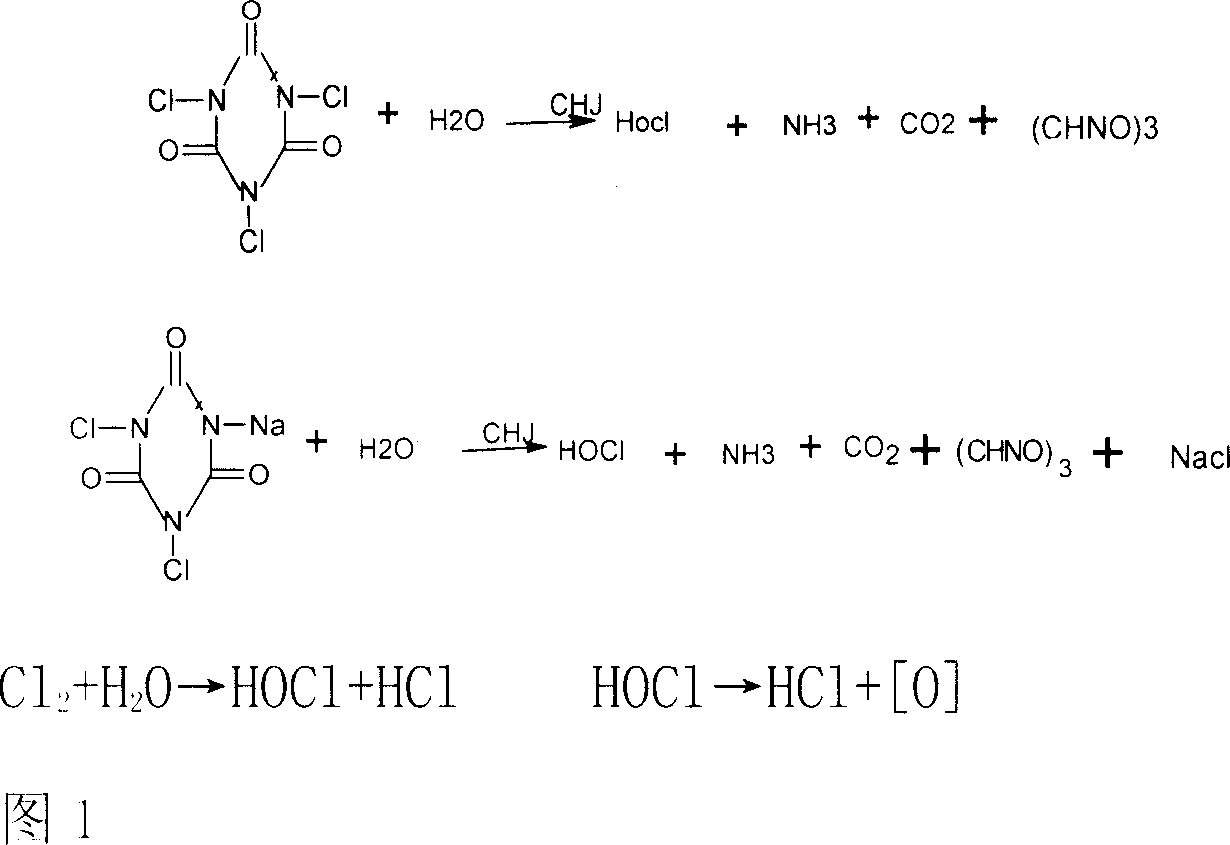

Method used

Image

Examples

Embodiment 1

[0107] A deodorizing, bleaching and disinfecting two-component solid composition and a preparation method, wherein the mass percentage of each component is:

[0108] A component: Sodium dichloroisocyanurate 35%-55%

[0109] Silica powder 0.5%-1%

[0110] Boric acid 2%-6%

[0111] Sodium Benzoate 3%-7%

[0112] Sodium carbonate 20%-30%

[0113] Cellulose 1%-8%

[0114] B component: Sodium chlorite 2%-18%

[0115] Sodium perborate 2%-9%

[0116] Sodium bisulfate 2%-18%

[0118] Sodium Benzoate 2%-8%

[0119] Boric acid 2%-6%

[0120] Cellulose salt 2%-8%

[0121] Sodium sulfate 30%-40%

[0122] Sodium polyphosphate 1%-10%

[0123] Silica powder 0.5%-2%

[0124] Drying after pulverization, passing through a 100-mesh sieve, direct tableting, using a 25 or 33 punch rotary tablet press, selecting a suitable die, adjusting the machine pressure, ...

Embodiment 2

[0126] A deodorizing, bleaching and disinfecting two-component solid composition and a preparation method thereof, the mass percent of each component is:

[0127] A component: trichloroisocyanuric acid 3%-55%

[0128] Silica powder 0.2%-1%

[0129] Boric acid 2%-6%

[0130] Sodium Benzoate 1%-8%

[0131] Sodium carbonate 20%-50%

[0132] Cellulose salt 1%-18%

[0133] B component: sodium chlorate 2%-18%

[0134] Sodium percarbonate 2%-9%

[0135] Sodium bisulfate 2%-8%

[0137] Sodium Benzoate 2%-8%

[0138] Boric acid 2%-8%

[0139] Cellulose 2%-8%

[0140] Sodium sulfate 30%-40%

[0141] Sodium polyphosphate 1%-10%

[0142] Silica powder 0.5%-2%

Embodiment 3

[0144] A deodorizing, bleaching and disinfecting two-component solid composition and a preparation method thereof, the mass percent of each component is:

[0145]A component: Calcium hypochlorite 5%-55%

[0146] Silica powder 0.2%-1%

[0147] Boric acid 2%-6%

[0148] Sodium Benzoate 1%-8%

[0149] Sodium bicarbonate 20%-40%

[0150] Cellulose 1%-8%

[0151] B component: sodium chlorate 2%-18%

[0152] Sodium percarbonate 2%-9%

[0153] Sodium bisulfate 2%-18%

[0155] Sodium Benzoate 2%-8%

[0156] Boric acid 2%-8%

[0157] Cellulose salt 2%-8%

[0158] Sodium sulfate 30%-40%

[0159] Sodium polyphosphate 1%-10%

[0160] Silica powder 0.5%-2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com