Polyester/fibrous clay nano composite material, preparation method and application thereof

A nanocomposite, fibrous technology, applied in the field of polyester/fibrous clay nanocomposite and its preparation, can solve the problems of increased material density, decreased surface gloss and transparency, and excessive size, and achieves interface adhesion. Enhanced junction, excellent mechanical properties, and the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of organic clay

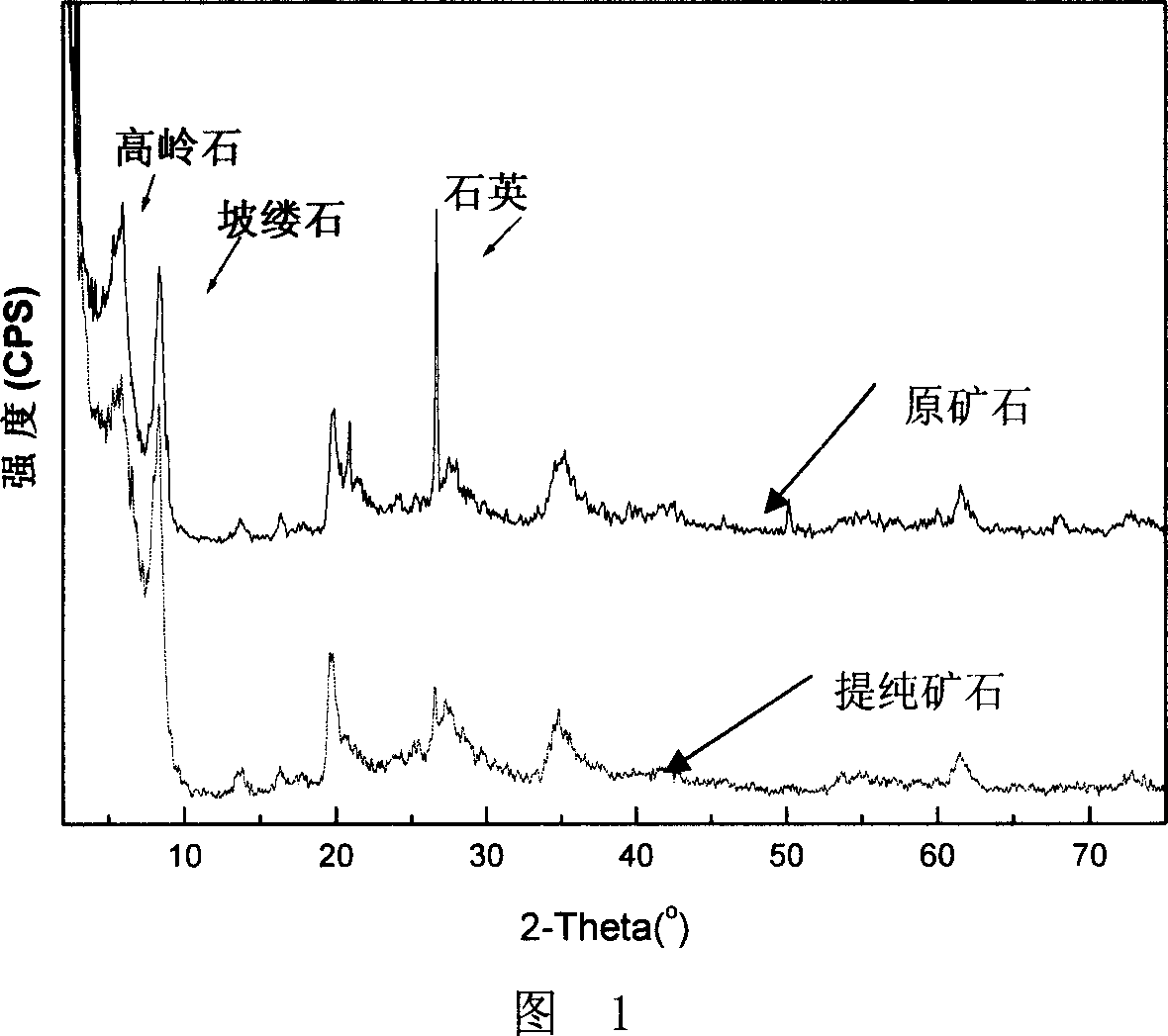

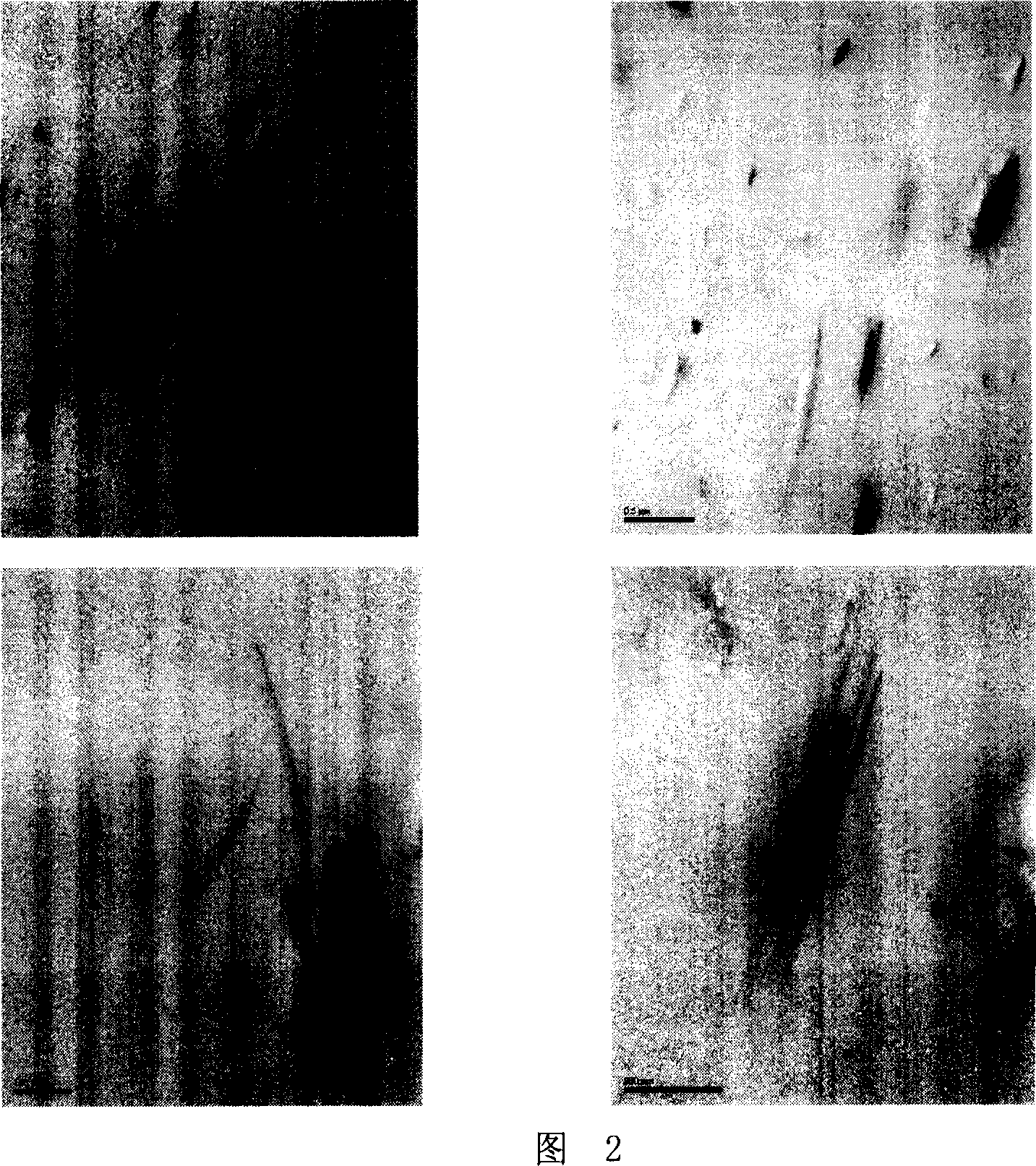

[0025] Palygorskite clay, commonly known as attapulgite, its typical chemical formula is Si 8 Mg 5 o 20 (OH) 2 (OH 2 ) 4 4H 2 O. Its structure can be divided into three layers, the upper and lower layers are silicon-oxygen tetrahedrons, and the middle layer is aluminum-oxygen or magnesium-oxygen octahedrons. These structural units are staggered in a grid form to form a double-chain channel crystal structure. Due to lattice substitutions in the structure, the crystals contain variable amounts of exchangeable Na + , Ca 2+ , Mg 2+ 、Al 3+ Plasma. The crystals are needle-like and fibrous aggregates. The diameter of the rod crystal is about 5-50 nanometers, the length is about 100-1000 nanometers, and the long diameter is relatively large, which varies with the place of origin.

[0026] Add 400 grams of palygorskite raw ore (abundance about 30%) and 1.0 grams of sodium silicate to 2000 milliliters of water, stir at high speed for ...

Embodiment 2

[0035] 1. Preparation of palygorskite clay

[0036] Add 400 grams of palygorskite raw ore (abundance about 30%) and 1.0 grams of sodium pyrophosphate to 2000 milliliters of water, stir vigorously for two hours, and remove sediments such as gravel in the lower layer after settling. The suspension in the upper layer was centrifuged and dried at 100° C. to prepare the purified palygorskite.

[0037] Take 10.0 grams of purified palygorskite, add 2.0 grams of hexadecyltriphenylphosphine bromide, 300 grams of water, stir vigorously, keep the temperature at 90°C for four hours, centrifuge and wash three times to prepare organic palygorskite clay.

[0038] Take 10.0 g of palygorskite clay after organicization, add 0.1 g of titanate coupling agent NDZ102, 50 ml of toluene, stir vigorously for two hours, centrifuge and wash three times until the pH is 7, dry, grind, and pass through a 300-mesh sieve to obtain Organic clay 2.

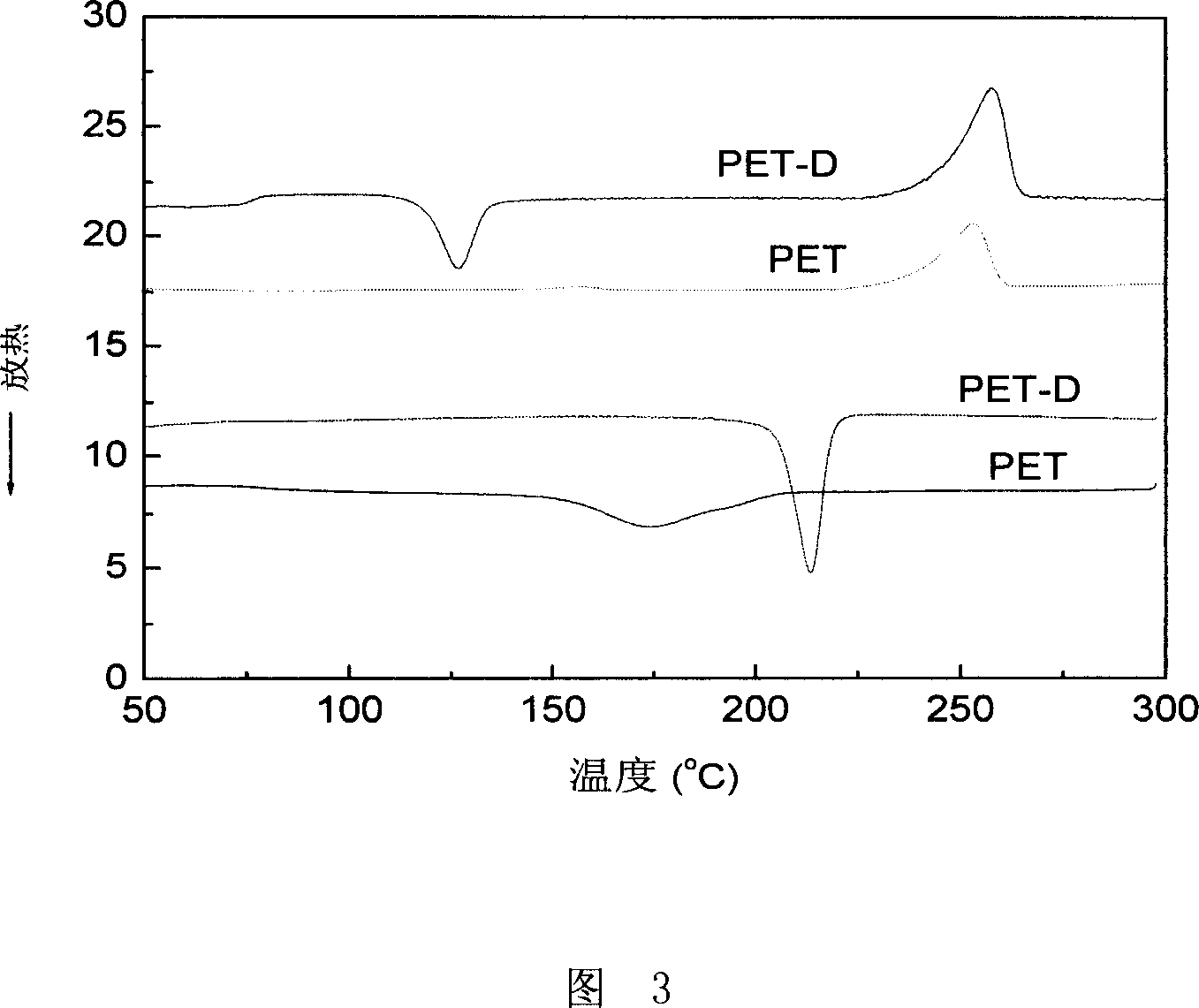

[0039] 2. Preparation of composite materials by direct es...

Embodiment 3

[0043] 1. Preparation of organic clay

[0044] Add 400 grams of palygorskite raw ore (abundance about 30%) and 1.0 grams of sodium metaphosphate to 2000 milliliters of water, stir vigorously for two hours, and remove sediments such as gravel in the lower layer after settling. The suspension in the upper layer was centrifuged and dried at 100° C. to prepare the purified palygorskite.

[0045] Get 10.0 grams of palygorskite after purification, add 0.1 gram of coupling agent KH570, 10 grams of acetic acid, 200 grams of water, stir vigorously for two hours, centrifugally wash three times until the pH is 7, and prepare palygorskite clay after surface treatment .

[0046] Take 10.0 grams of palygorskite clay after surface treatment, add 2.0 grams of polyvinylpyrrolidone, 300 grams of water, stir vigorously, keep the temperature at 90°C for four hours, centrifuge, wash with water three times, dry, grind, and pass through a 300-mesh sieve to obtain organic clay3.

[0047] 2. Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com