Decomposition agent for extracting fuel oil from dirty oil mud

A decomposing agent and fuel oil technology, which is applied in the direction of fuel, sludge treatment, liquid carbon-containing fuel, etc., can solve the problems of incomplete decomposition of sludge, unsatisfactory decomposing and purification effect of sludge, insufficient alkalinity of decomposer, etc. Achieve the effect of improving the decomposition and purification effect, thoroughly decomposing sludge and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

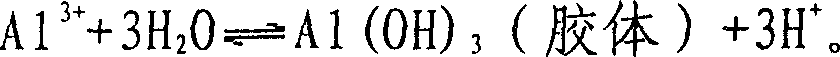

Method used

Image

Examples

Embodiment 1

[0015] Example 1: A decomposition agent for extracting fuel oil from sludge. The decomposition agent may include the following components (weight percentage): silica gel 65%, alum 20%, sodium hydroxide 7%, potassium permanganate 0.1% , Water 3.9%, sodium carbonate 4%.

Embodiment 2

[0016] Example 2: A decomposing agent for extracting fuel oil from sludge. The decomposing agent may include the following components (weight percentage): silica gel 75%, alum 14%, sodium hydroxide 4%, potassium permanganate 0.05% , Water 3.95%, sodium carbonate 3%.

Embodiment 3

[0017] Example 3: A decomposer for extracting fuel oil from sludge. The decomposer includes the following components (weight percentage): silica gel 70%, alum 15%, sodium hydroxide 8%, potassium permanganate 0.1%, Water 3.9%, sodium carbonate 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com