Functional molybdate film and its prepn

A molybdate and thin film technology, applied in the field of wet chemical method oxide thin film preparation, can solve the problems of not discussing obtaining thin film materials, being difficult to implement, and not disclosing the preparation conditions of calcium salt and molybdate solution, etc. Health and environmental protection, guaranteed performance, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of a solution containing Mo ion complexes

[0047] Molybdic acid was dissolved in 15ml of a mixed solvent consisting of propylene glycol (volume percent 25%), propylene glycol methyl ether (volume percent 50%) and glacial acetic acid (volume percent 25%) at normal temperature and pressure to obtain clear and transparent Mo A complex solution with an ion concentration of 1.2M;

[0048] (2) Preparation of a solution containing metal ion complexes

[0049] Lithium carbonate was dissolved in 18ml of a mixed solvent consisting of propylene glycol (volume percent 25%), propylene glycol methyl ether (volume percent 50%) and glacial acetic acid (volume percent 25%) at normal temperature and pressure to obtain clear and transparent Li + A complex solution with a concentration of 1.0M;

[0050] (3) Preparation of molybdate precursor solution

[0051] Stir and mix the above two complex solutions at normal pressure and 10°C for 45 minutes and then let it stand fo...

Embodiment 2

[0056] (1) Preparation of a solution containing Mo ion complexes

[0057] Ammonium molybdate and molybdic acid (the mass ratio of ammonium molybdate and molybdic acid is 3: 1) are dissolved in 15 ml of propylene glycol (volume percentage 65%), propylene glycol methyl ether (volume percentage 15%) and In the mixed solvent that glacial acetic acid (volume percent 20%) forms, obtains clear and transparent Mo ion concentration and is the complex solution of 0.6M;

[0058] (2) Preparation of a solution containing metal ion complexes

[0059] Dissolve 0.0045 moles of lithium carbonate and 0.0045 moles of potassium carbonate in 22.5ml of propylene glycol (volume percent 65%), propylene glycol methyl ether (volume percent 15%) and glacial acetic acid (volume percent 20%) at normal temperature and pressure. In the mixed solvent, a clear and transparent complex solution with an alkali metal ion concentration of 0.4M is obtained;

[0060] (3) Preparation of molybdate precursor solution...

Embodiment 3

[0066] (1) Preparation of a solution containing Mo ion complexes

[0067] Ammonium molybdate was dissolved in 8ml of glycerol solvent at normal temperature and pressure to obtain a clear and transparent complex solution with Mo ion concentration of 0.75M;

[0068] (2) Preparation of a solution containing metal ion complexes

[0069] Dissolve barium carbonate in 60ml glycerol solvent at normal temperature and pressure to obtain clear and transparent Ba 2+ The concentration is 0.1M complex solution;

[0070] (3) Preparation of molybdate precursor solution

[0071] Stir and mix the above two complex solutions at normal pressure and 25°C for 20 minutes and then let it stand for 40 minutes to obtain the barium molybdate precursor solution that meets the requirements;

[0072] (4) Film formation and heat treatment by spin coating technology

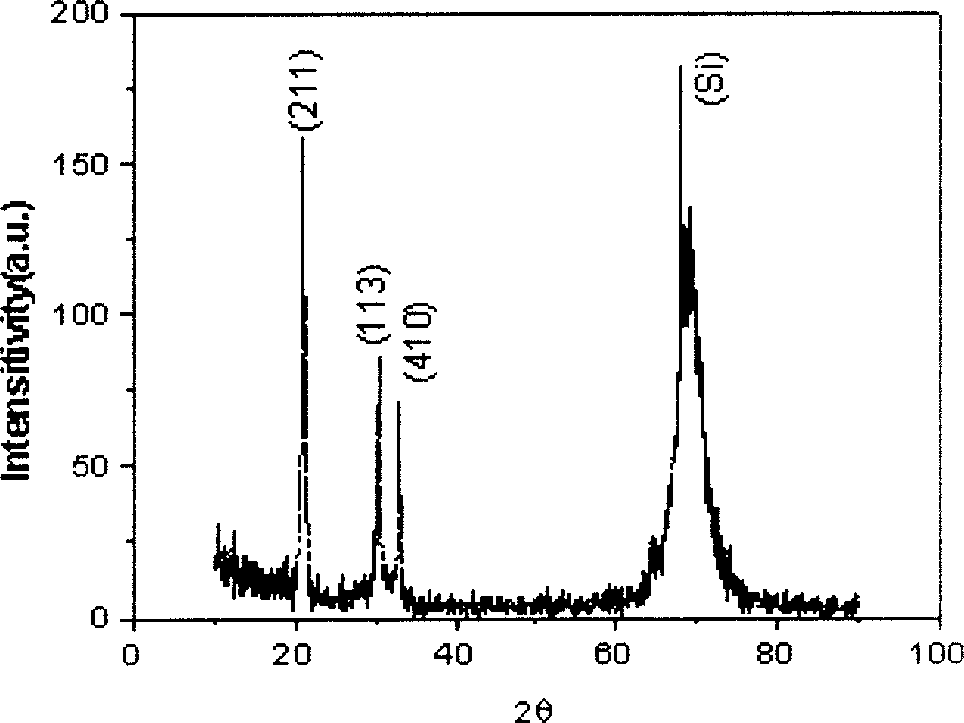

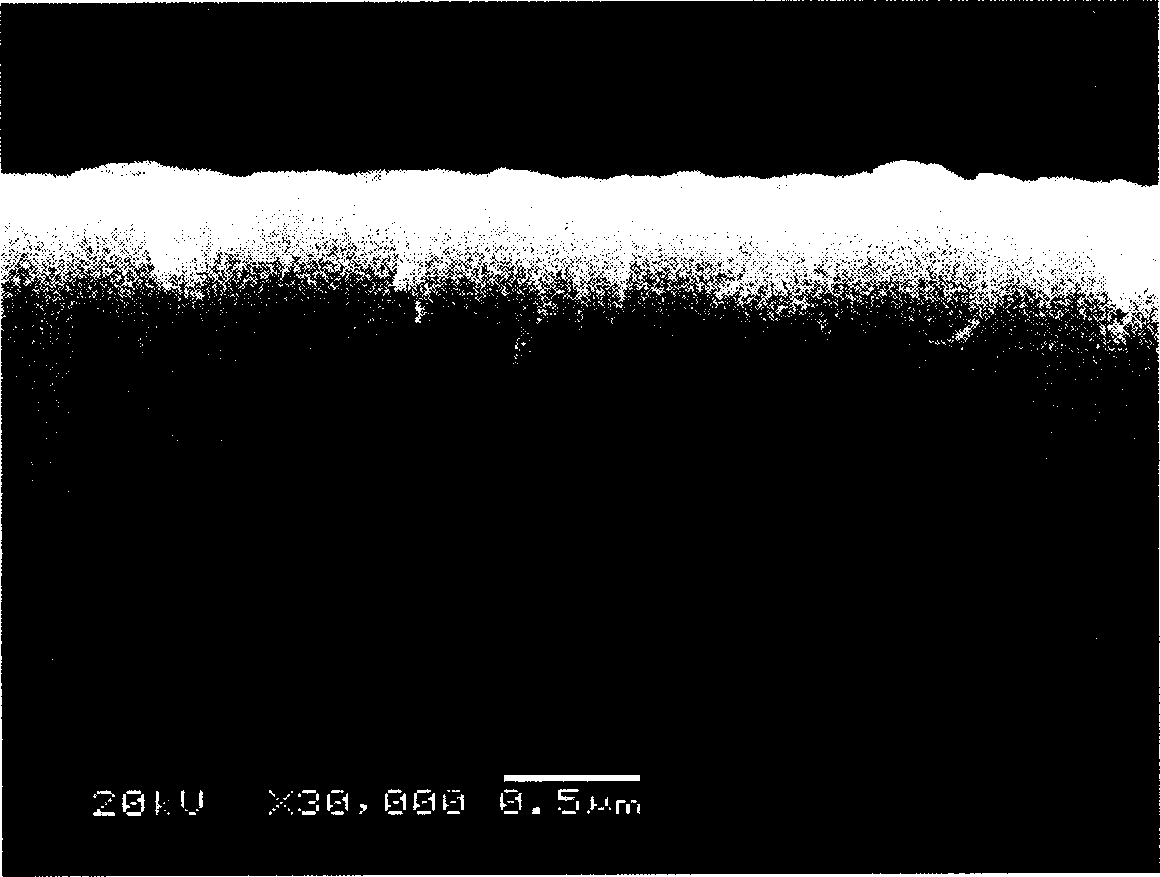

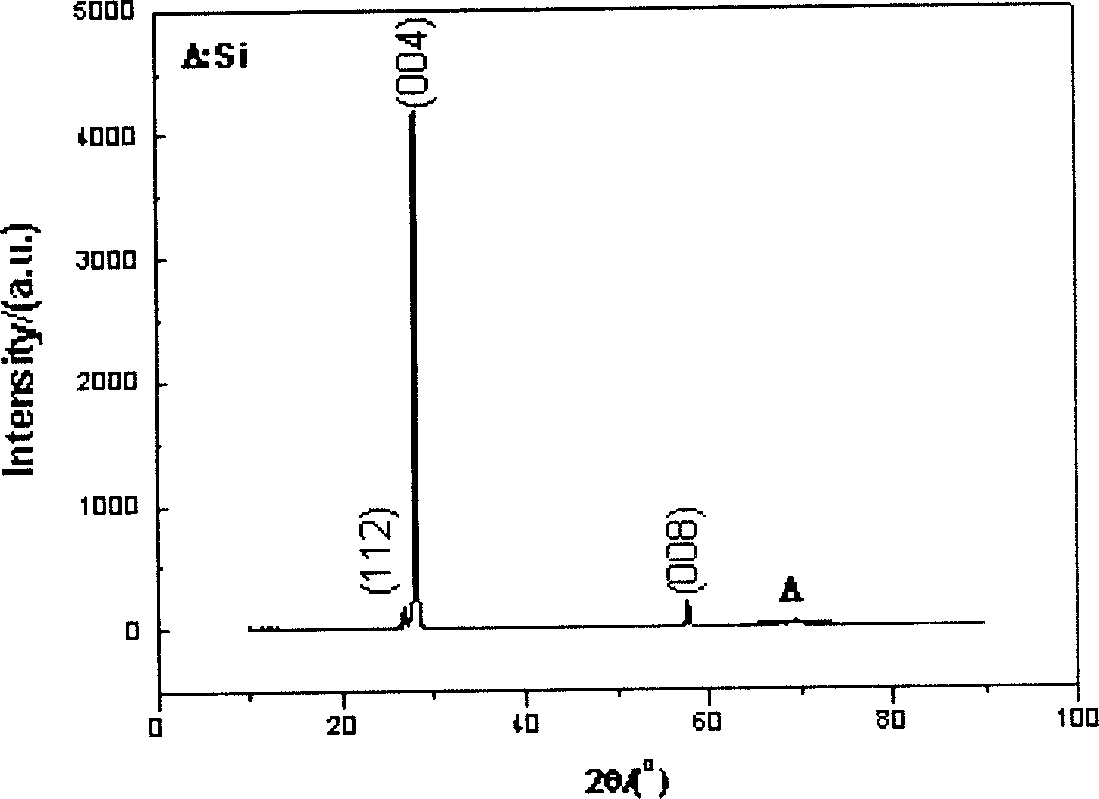

[0073] Under normal pressure and room temperature, use the spin-coating technique to form a thin film of the barium molybdate precursor so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com