Prepn of high molecular weight polylactic acid

A high molecular weight, polylactic acid technology, applied in the field of polylactic acid preparation, can solve the problems of high cost, complicated operation, and environmental pollution, and achieve the effect of low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

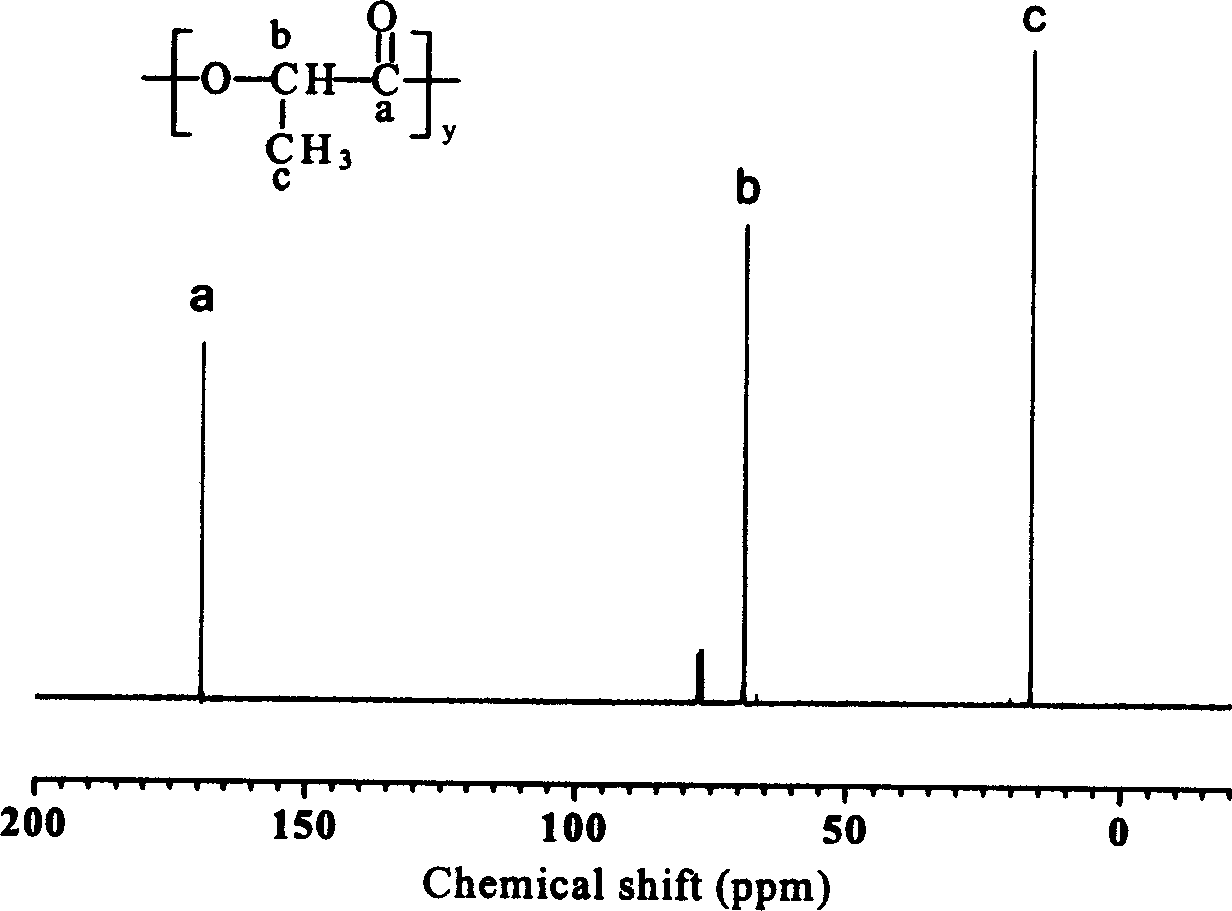

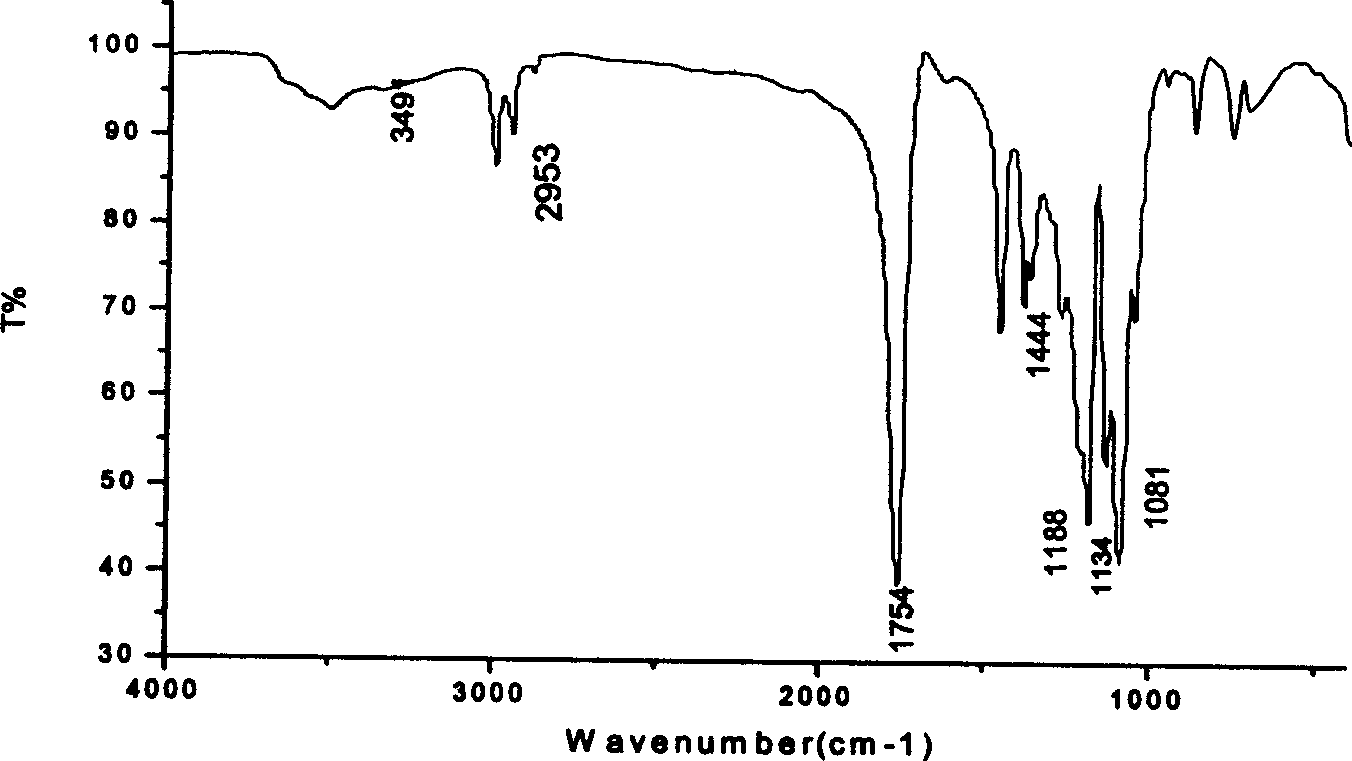

[0017] Add L-lactic acid with a concentration of 90% into a three-necked flask with a stirring device, slowly heat to 100°C, depressurize to 1000Pa, stir and dehydrate for 3 hours; then remove the vacuum, and raise the temperature to 160°C in a nitrogen atmosphere , add L-lactic acid weight 1wt% stannous chloride as a catalyst, react for 7 hours; then gradually reduce the pressure to 200Pa within 7 hours, continue to react for 30 hours. figure 1 For the nuclear magnetic resonance spectrum of the polylactic acid prepared in this embodiment, figure 2 Its infrared spectrum. The spectrogram proves the structure of the synthesized polylactic acid, and the weight average molecular weight of the polylactic acid obtained by the viscosity method is 116,000.

Embodiment 2

[0019] Add L-lactic acid with a concentration of 90% into a three-necked flask with a stirring device, slowly heat to 150°C, depressurize to 10,000Pa, stir and dehydrate for 15 hours; then remove the vacuum, and raise the temperature to 220°C in a nitrogen atmosphere , add tetrabutyl titanate with 4wt% L-lactic acid weight as a catalyst, and react for 1 hour; then gradually reduce the pressure to 1000 Pa within 50 hours, and continue the reaction for 30 hours. The weight-average molecular weight of polylactic acid obtained by viscometry is 91,000.

Embodiment 3

[0021] Add L-lactic acid with a concentration of 90% into a three-necked flask with a stirring device, slowly heat to 70°C, depressurize to 300Pa, stir and dehydrate for 1 hour; then remove the vacuum, and raise the temperature to 100°C in a nitrogen atmosphere , adding tetrabutyl titanate with 5wt% L-lactic acid weight as a catalyst, and reacting for 50 hours; then gradually reducing the pressure to 10 Pa within 1 hour, and continuing the reaction for 40 hours. The weight-average molecular weight of polylactic acid obtained by viscometry is 120,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com