Preparation method of indium tin oxide precusor size and ITO thin film

The technology of indium tin oxide and indium tin hydroxide is applied in the field of indium tin oxide precursor slurry, which can solve the problems of high preparation cost, high cost, high vacuum degree and the like, and achieve the effect of uniform and flat film surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

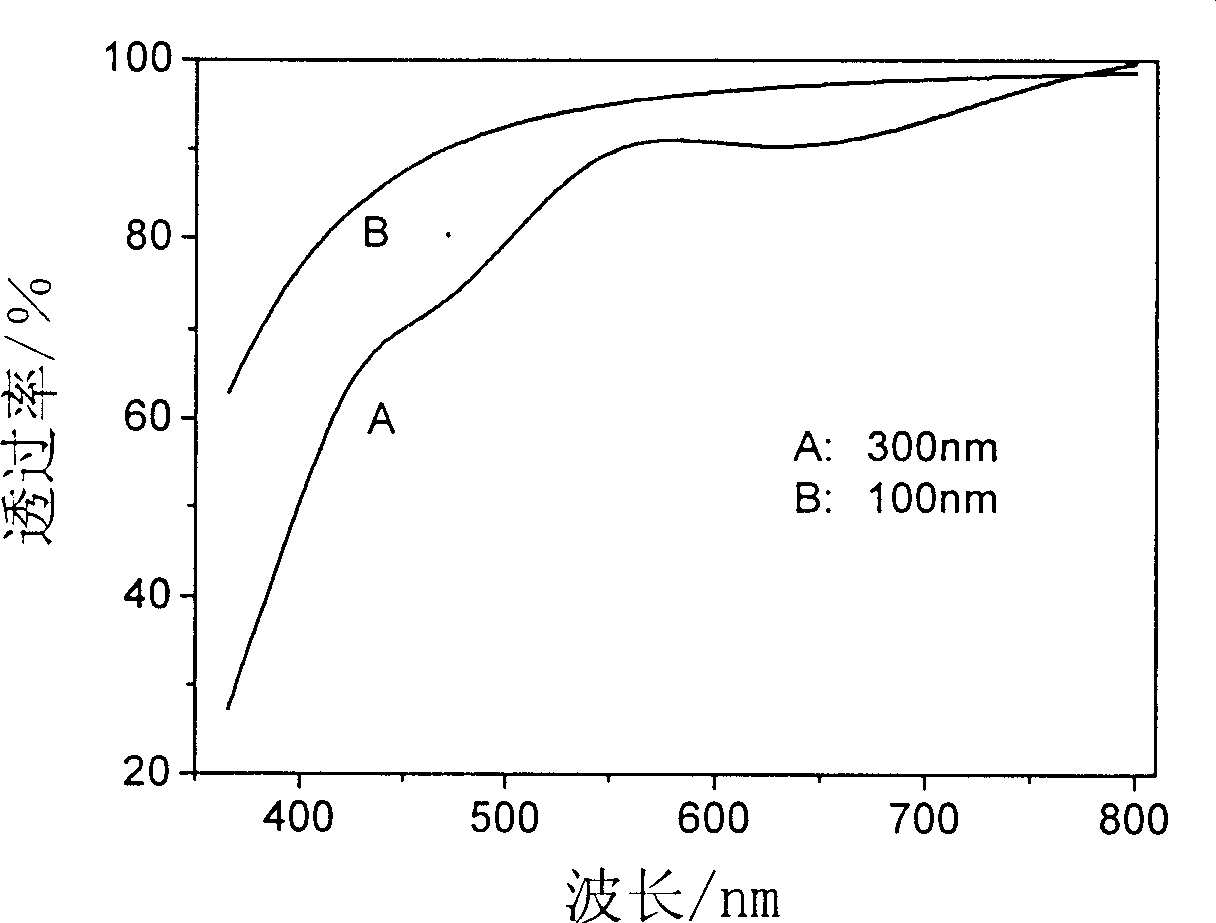

Image

Examples

Embodiment 1

[0014] Weigh 1.435 grams of metal indium and add it to concentrated nitric acid to dissolve, weigh 0.451 grams of SnCl 4 ·5H 2 Dissolve O in deionized water, then mix the two solutions to obtain a solution with a metal ion concentration of 0.1-2.0 mol / L, add 0.5%-20% PEG, after it is completely dissolved, add ammonia water dropwise under stirring until it becomes alkaline , aging for a period of time; then wash the precipitate with deionized water until there are no other impurity ions, centrifuge, then soak the washed indium tin hydroxide with absolute ethanol for 3 times, add absolute ethanol and a small amount of acetic acid, ethanolamine , Tween and PVP to prepare the indium tin oxide precursor slurry.

Embodiment 2

[0016] Weigh 2.296 grams of metal indium and add it to concentrated nitric acid to dissolve, weigh 0.718 grams of SnCl 4 ·5H 2 O was dissolved in deionized water, and then the two solutions were mixed to obtain In 3+ For a solution with a concentration of 0.1-2.0mol / L, add 0.5%-20% Tween, after it is completely dissolved, add ammonium carbonate solution dropwise under stirring until alkaline, and age for a period of time; then wash the precipitate with deionized water Centrifuge until there are no other impurity ions, then soak and wash the indium tin hydroxide with absolute ethanol for 3 times, add isopropanol and a small amount of acetic acid, PEG, ethanolamine and PVP to stir to obtain the indium tin oxide precursor slurry .

Embodiment 3

[0018] Weigh 2.296 grams of metal indium and dissolve it in concentrated nitric acid, weigh 0.243 grams of metal tin and dissolve it in hydrochloric acid, then mix the two solutions to obtain a solution with a metal ion concentration of 0.1 to 2.0 mol / L, and add 0.5% to 20% of After PEG is completely dissolved, add urea solution dropwise under stirring until it becomes alkaline, and age for a period of time; then wash the precipitate with deionized water until there are no other impurity ions, separate it by centrifugation, and then soak the washed indium with absolute ethanol tin hydroxide 3 times, adding absolute ethanol and a small amount of acetic acid, PEG, ethanolamine, Tween and PVP and stirring to prepare indium tin oxide precursor slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com