Double-colour indium-gallium-arsenide infrared detector and producing method and application thereof

An infrared detector, indium gallium arsenic technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of large volume and weight of the infrared detection system, high power consumption of the detection system, low cost performance, etc. problem, to achieve the effect of light weight, improved anti-interference, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

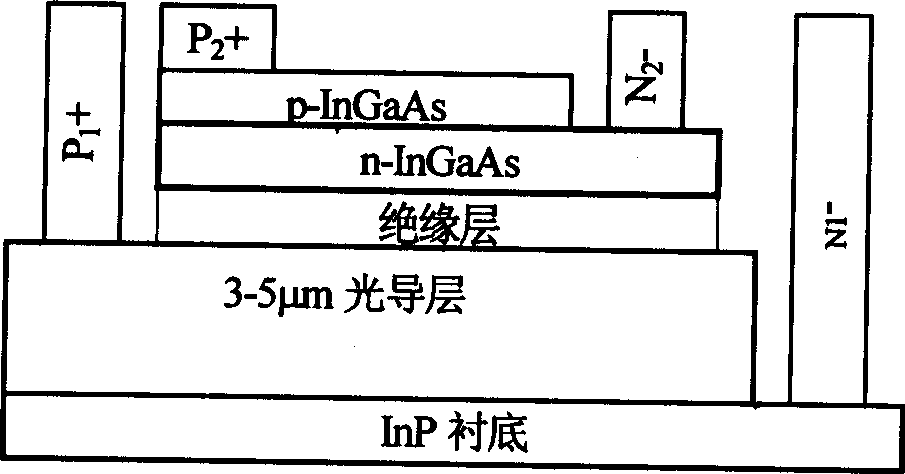

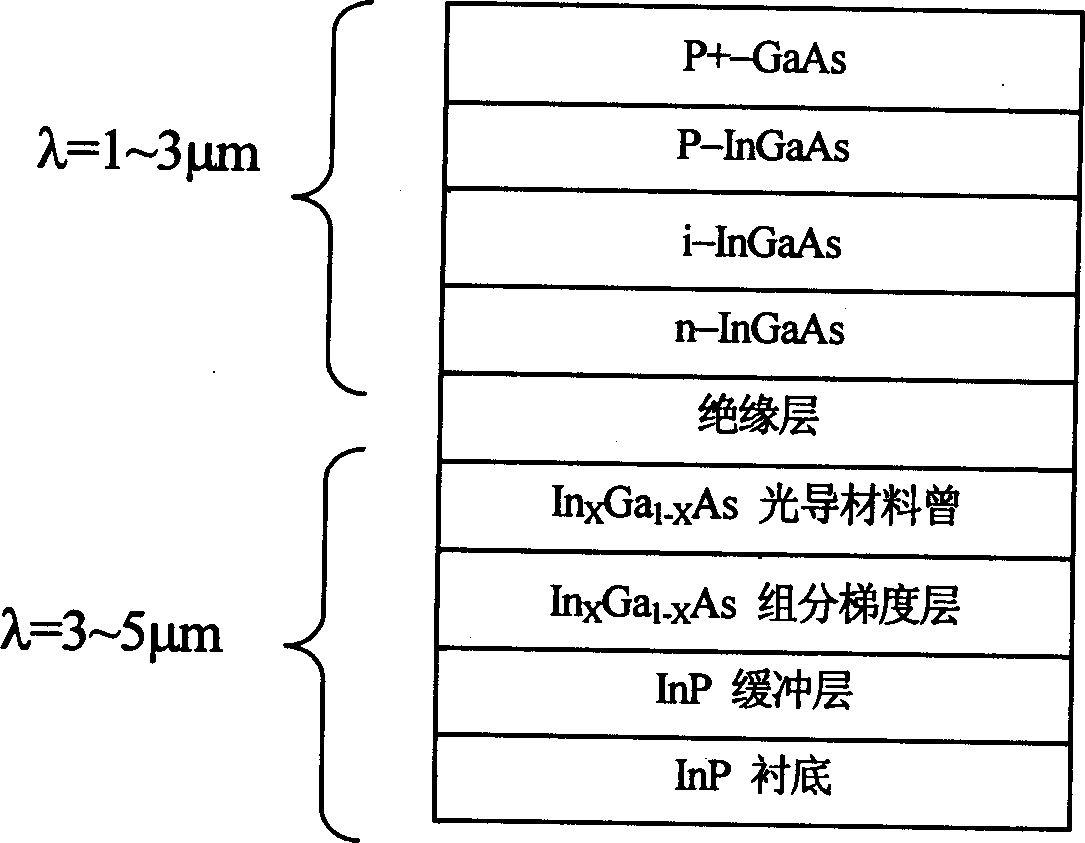

[0025] Adopt the method of the present invention to prepare two-color InGaAs infrared detector: form InP buffer layer, InP buffer layer, InP substrate with epitaxy method x Ga 1-x As composition gradient layer, In x Ga 1-x As photoconductive material layer and other structures; continue to grow the insulating layer, and then use the epitaxy method to form N-type-InGaAs layer, I-type-InGaAs layer, P-type-InGaAs layer, P+ electrode-GaAs layer and other structures. get figure 2 Infrared epitaxial wafer layers shown.

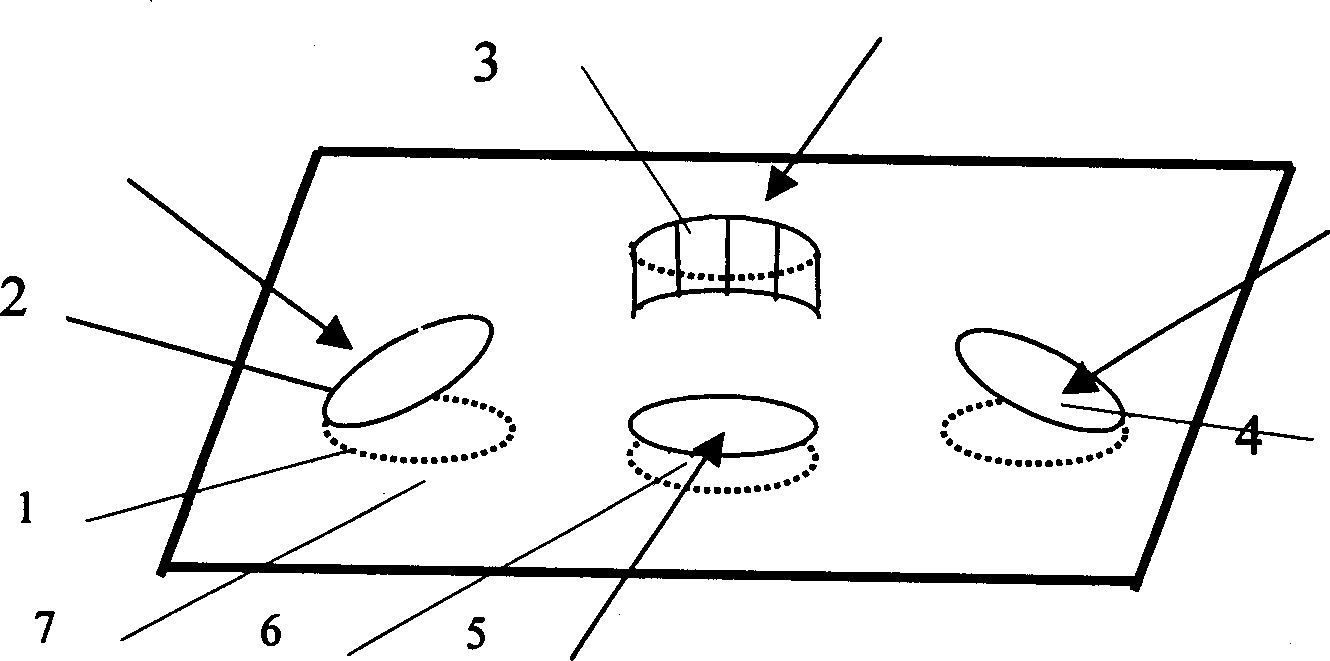

[0026] After the epitaxial wafer is grown by the epitaxial method, the surface of the N-type layer is etched using the semiconductor planar process technology, photolithography and chemical etching, and then the ohmic contact electrode pattern of the N-type layer is formed by photolithography. The evaporation method evaporates the N-type layer ohmic contact electrode, and the P-type layer ohmic contact electrode can be made in the same way, that is, the manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com