Tetrahydro furfuryl alcohol preparing process

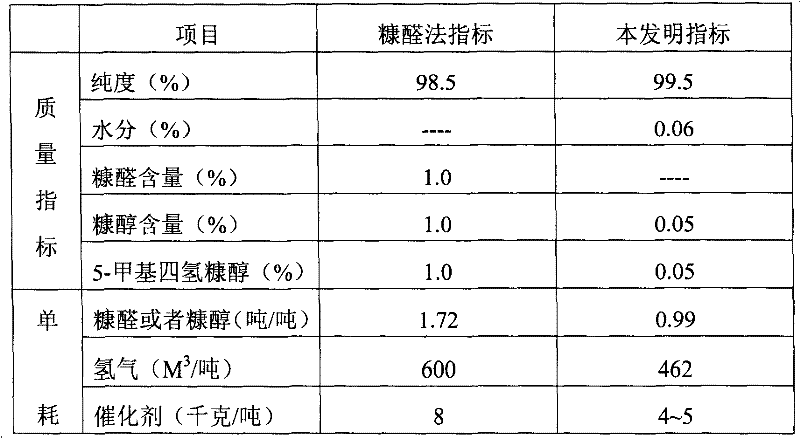

A tetrahydrofurfuryl alcohol production method technology, applied in the field of tetrahydrofurfuryl alcohol production method, can solve the problems of high temperature, high pressure, fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of catalyst

[0025] 10Kg of nickel-aluminum alloy was slowly added to 50Kg of 30% sodium hydroxide solution. Because the reaction exothermed violently, the addition rate was controlled so that the temperature was 30°C-40°C. After the addition is complete, when the foam disappears, the temperature is raised to 65° C., the temperature is kept for 1 hour, and after washing twice, a catalyst with a composition content of 45% nickel, 51% aluminum and 4% molybdenum is obtained. Soak in water for later use.

[0026] (2) Preparation of tetrahydrofurfuryl alcohol

[0027] Add 1000Kg of furfuryl alcohol (purity ≥98.5%, moisture ≤0.2%, residual aldehyde ≤0.5%) and 6Kg of the catalyst prepared into the reaction kettle, vacuum out the air in the kettle, and carry out hydrogenation in the form of a suspended bed. During the reaction, the reaction pressure was 1.5 MPa, the temperature was 40°C-50°C, after hydrogenation for 7 hours, the temperature was raised to 95-100°C, a...

Embodiment 2

[0029] (1) Preparation of catalyst

[0030] 10Kg of nickel-aluminum alloy was slowly added to 57Kg of 35% sodium hydroxide solution. Because the reaction exothermed violently, the addition rate was controlled so that the temperature was 45°C-50°C. After the addition is complete, when the foam disappears, the temperature is increased to 55° C., the temperature is kept for 2 hours, and after washing twice with water, a catalyst with a composition content of 20% nickel, 70% aluminum and 10% molybdenum is prepared. Soak in water for later use.

[0031] (2) Preparation of tetrahydrofurfuryl alcohol

[0032] Add 1000Kg of furfuryl alcohol (purity ≥98.5%, moisture ≤0.2%, residual aldehyde ≤0.5%) and 1Kg of the prepared catalyst into the reaction kettle, vacuum out the air in the kettle, and carry out hydrogenation in the form of a suspended bed. During the reaction, the pressure was 1.6 MPa, and the temperature was 45°C to 55°C. After hydrogenation for 7 hours, the temperature was raised ...

Embodiment 3

[0034] (1) Preparation of catalyst

[0035] 10Kg of nickel-aluminum alloy was slowly added to 62.5Kg of 40% sodium hydroxide solution. Because the reaction exothermed violently, the addition rate was controlled so that the temperature was 40°C to 45°C. After the addition is complete, when the foam disappears, the temperature is raised to 65° C., the temperature is kept for 1 hour, and after washing twice, a catalyst with a composition content of 50% nickel, 49% aluminum and 1% molybdenum is prepared. Soak in water for later use.

[0036] (2) Preparation of tetrahydrofurfuryl alcohol

[0037] Add 1000Kg of furfuryl alcohol (purity ≥98.5%, moisture ≤0.2%, residual aldehyde ≤0.5%) and 3Kg of the catalyst prepared into the reaction kettle, vacuum out the air in the kettle, and carry out hydrogenation in the form of a suspended bed. During the reaction, the pressure was 2.0MPa, the temperature was 60℃~70℃, after 6h of hydrogenation, the temperature was raised to 100~105℃, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com