Electrolytic copper foil coating excellent in chemical resistance and cohesive force and its surface treatment method

A chemical resistance, electrolytic copper foil technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of unsatisfactory acid resistance deterioration rate of surface-treated copper foil, inconvenient operation, etc. Conducive to the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

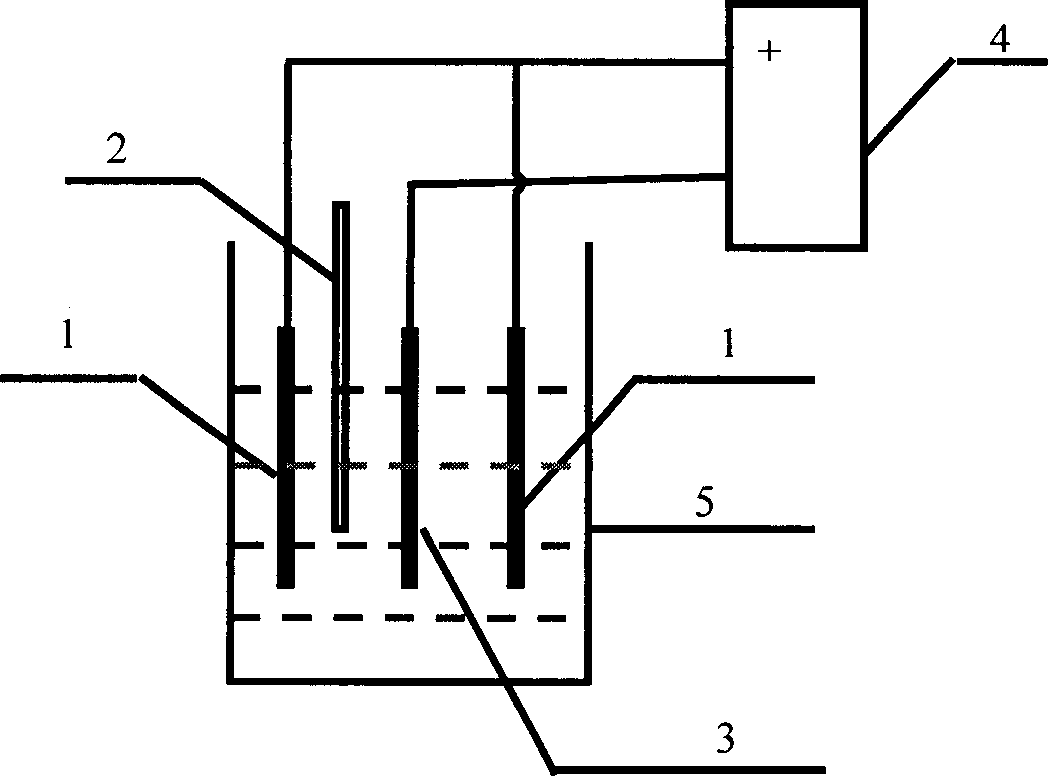

Method used

Image

Examples

specific Embodiment approach 1

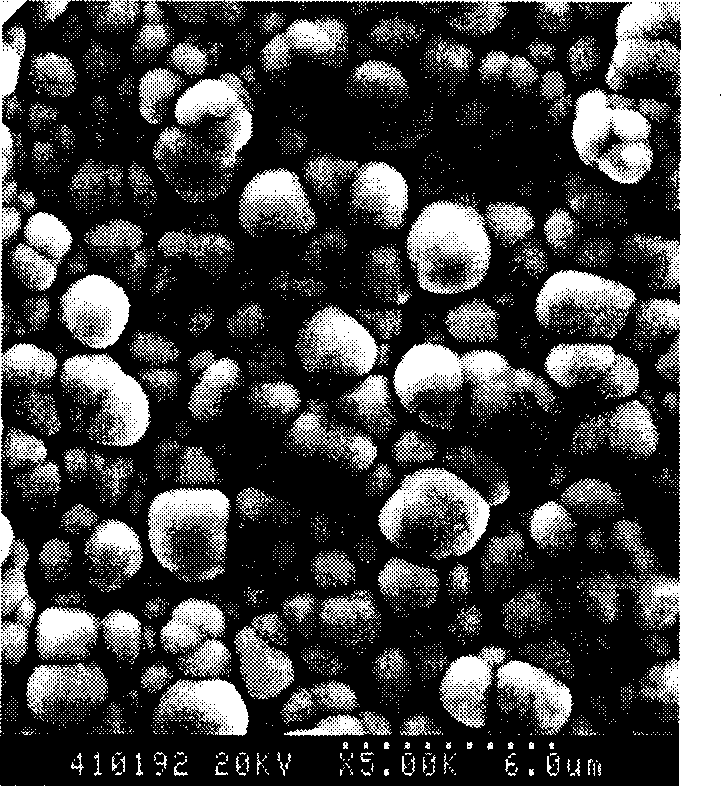

[0014] Embodiment 1: In the electrolytic copper foil coating in this embodiment, the mass percentage of Zn is 65-75%, the mass percentage of Ni is 20-30%, and the mass percentage of Sn is 3-7% %.

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass percentage of Zn in the electrolytic copper foil coating is 75%, the mass percentage of Ni is 22%, and the mass percentage of Sn is 3% %.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the mass percentage of Zn in the electrolytic copper foil coating is 70%, the mass percentage of Ni is 25%, and the mass percentage of Sn is 5% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com