Normal pressure cation dyeable polyester, textile product made from the same, and process for production of the same

A manufacturing method, a cationic technology, applied in the direction of one-component polyester rayon, one-component polyether ester rayon, one-component copolyester rayon, etc., can solve the increase in the difference in polyester physical properties , poor light fastness, fiber grade reduction and other problems, to achieve the effect of excellent light fastness, good operability and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

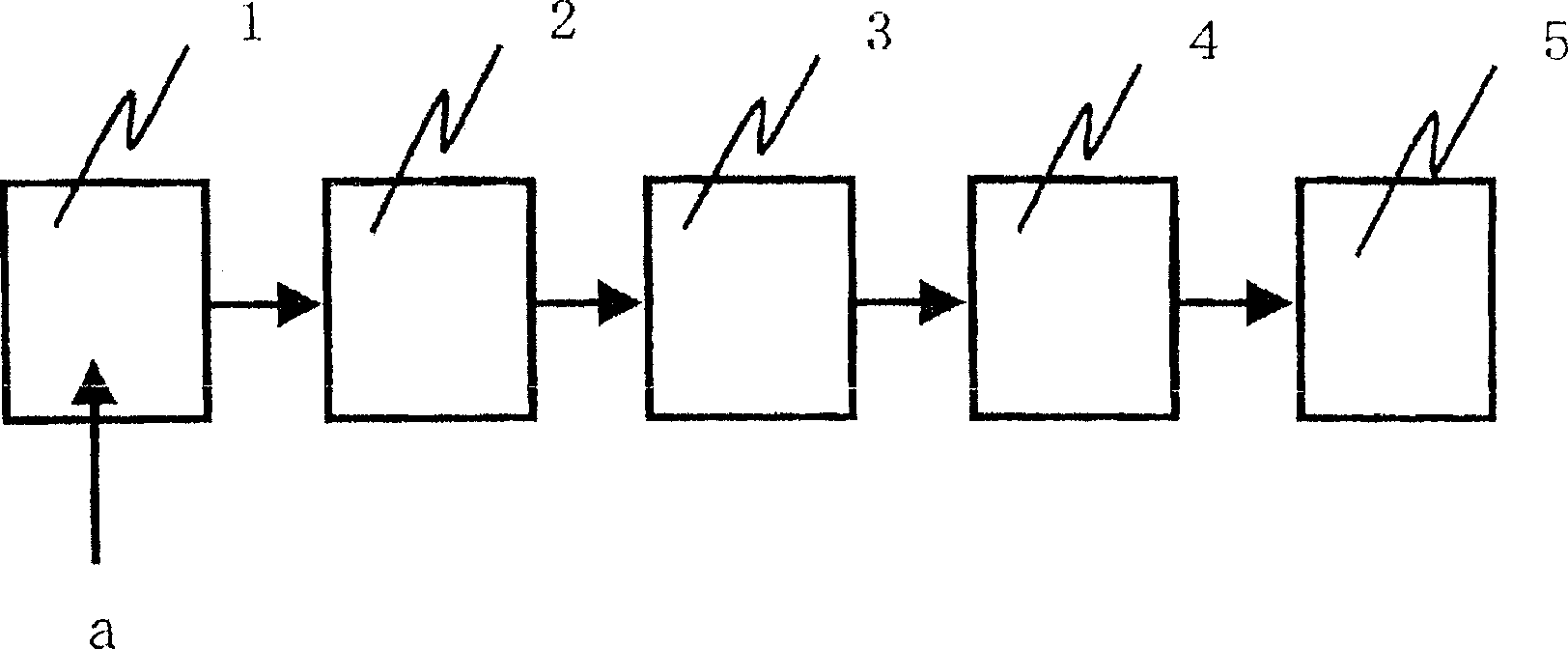

[0099] Terephthalic acid, ethylene glycol, and SIPE (accounting for 2.5 mol% of the acid component) were put into a slurry tank 1, and 320 ppm of titanium dioxide as a matting agent relative to the polymer, and 45 ppm of titanium dioxide relative to the polymer were added thereto. Trimethyl phosphate and 800 ppm of sodium acetate trihydrate adjust the pH of the slurry to 5.0, and then continuously supply the slurry to the first esterification tank 2 to make ethylene glycol relative to the dicarboxylic acid component The molar ratio is 1.0, and the reaction temperature is 270°C, the gauge pressure is 88.2kPa pressurized reaction, the esterification rate is 85%, and it is continuously supplied to the second esterification tank 3, and continuously added to the prepolymer. The polymer is 3% by weight of polyethylene glycol with a molecular weight of 200, and 0.2% by weight of IRGANOX (registered trademark) 245 (manufactured by Ciba-Geigy Corporation) as a hindered phenolic antioxid...

Embodiment 2~14

[0101] [Examples 2-14, Comparative Examples 1-10]

[0102] Except that the addition amount of SIPE, the addition amount of polyalkylene glycol, the molecular weight, the content of DEG, and the content of terminal carboxyl groups are changed as described in Table 1, the polycondensation reaction is carried out in the same manner as in Example 1 to obtain poly ester. The properties of the obtained polyester are shown in Table 1 and Table 2.

[0103] SIP composition

[0104] SIP composition

Embodiment 15~17

[0106] Polycondensation reaction was carried out in the same manner as in Example 1 except that the intrinsic viscosity ratio of the obtained polyester was adjusted to the value shown in Table 3 to obtain a polyester. Table 3 shows the evaluation results of the spinning operability of the obtained polyester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com