Preparation method of creature dross grain emulated crystallite glass composite plate

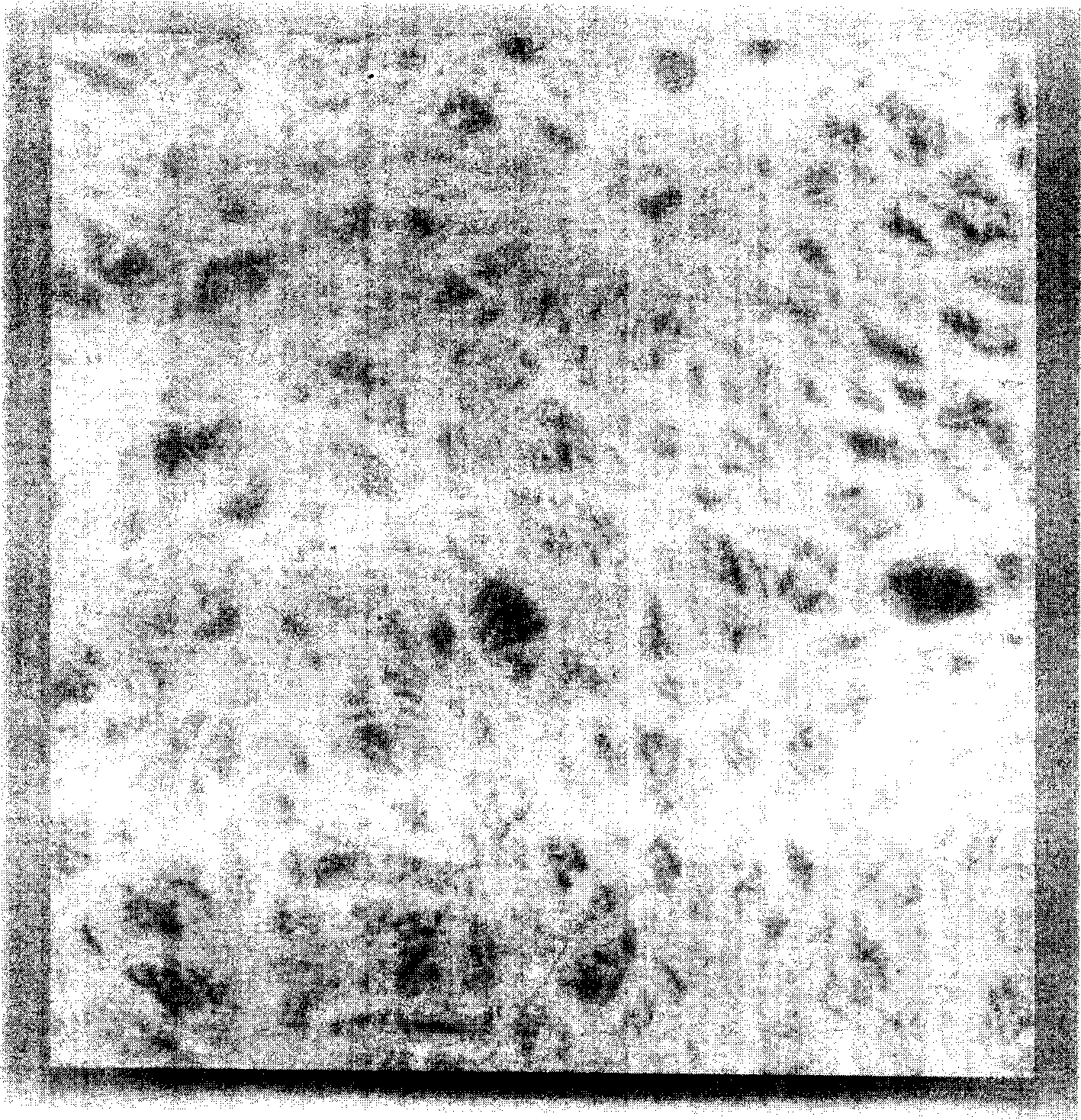

A glass-ceramic and biomimetic technology, applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problem of inability to prepare light-colored series of glass-ceramic products, difficult to effectively display biomimetic debris texture, The decorative surface of the product is difficult to generate texture and other problems, to achieve the effect of far-reaching resources and environmental protection significance, unique decorative effect, and rich texture and morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

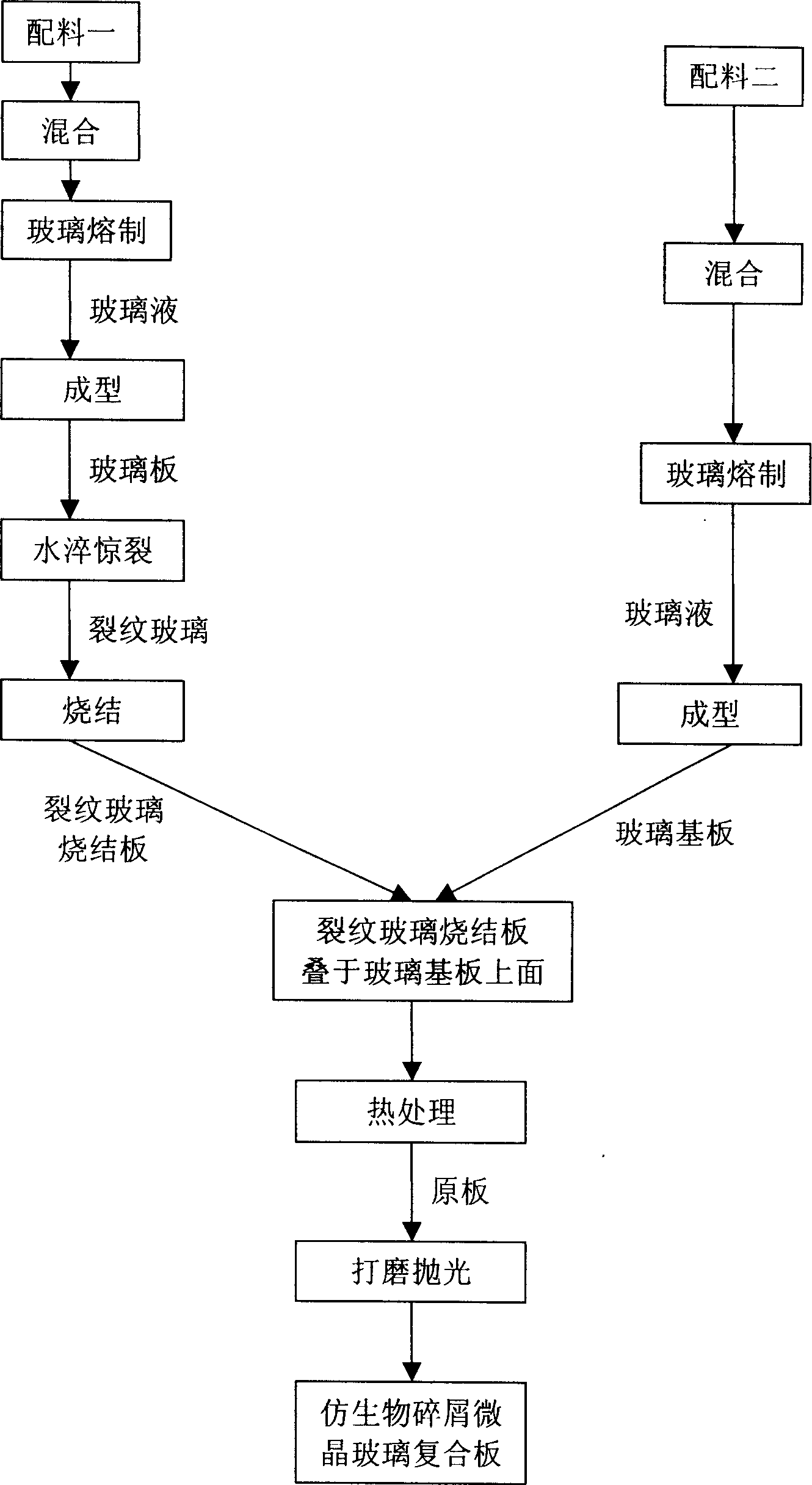

[0031]A method for preparing a glass-ceramic composite plate with bionic debris texture, comprising the steps of:

[0032] (1) Preparation of cracked glass sintered plate: adopt conventional mineral and chemical raw materials, the ratio of raw materials (expressed in mass percentage, the same in the following examples) is: 25.0% potassium feldspar, 30.0% quartz sand, 28.0% calcite, 3.5 % soda ash, 2.0% boric acid, 0.6% antimony trioxide, 4.5% barium carbonate, 4.5% zinc oxide, 0.7% ferric oxide, 1.2% manganese dioxide; the theoretical value of the chemical composition of the batch (in mass percentage means, the same in the following examples): 54.43% SiO 2 , 7.45%Al 2 o 3 , 19.25% CaO, 0.13% MgO, 2.00% K 2 O, 3.25% Na 2 O, 0.62% Sb 2 o 3 , 4.18% BaO, 5.10% ZnO, 1.20% B 2 o 3 , 0.8%TFe 2 o 3 , 1.2% MnO 2 , Other 0.39%. According to the formula, weigh the raw materials, mix them and put them into the crucible, melt them in a silicon-molybdenum rod high-temperature el...

Embodiment 2

[0037] A method for preparing a glass-ceramic composite plate with bionic debris texture, comprising the steps of:

[0038] (1) Preparation of cracked glass sintered plate: Same as Example 1.

[0039] (2) Preparation of glass substrate: with fly ash as the main raw material, the specific formula is: 45.0% fly ash, 14.0% quartz sand, 23.5% limestone, 10.0% dolomite, 5% soda ash, 2.0% titanium dioxide, 0.5% Antimony trioxide; the theoretical value of the chemical composition of the batch: 46.39% SiO 2 , 15.53%Al 2 o 3 , 23.23% CaO, 2.65% MgO, 0.72% K 2 O, 3.78% Na 2 O, 0.60% Sb 2 o 3 , 4.44% Fe 2 o 3 , 2.45%TiO 2 , Other 0.21%. According to the formula, weigh the raw materials, mix them and put them into a crucible, melt them in a silicon-molybdenum rod high-temperature electric furnace at 1500°C for 120 minutes, then lower the temperature to 1400°C for 60 minutes, clarify and homogenize them into glass liquid. The molten glass is poured into a refractory mold, heat-p...

Embodiment 3

[0043] A method for preparing a glass-ceramic composite plate with bionic debris texture, comprising the steps of:

[0044] (1) Preparation of cracked glass sintered plate: Same as Example 1.

[0045] (2) Preparation of glass substrate: coal gangue as the main raw material, the specific formula is: 55.0% coal gangue, 5.0% quartz sand, 23.5% limestone, 9.0% dolomite, 5% soda ash, 1.5% titanium dioxide, 0.5% trioxide Chromium, 0.5% antimony trioxide; the theoretical value of the chemical composition of the batch: 47.31% SiO 2 , 14.00%Al 2 o 3 , 21.28% CaO, 3.18% MgO, 1.16% K 2 O, 3.93% Na 2 O, 0.65% Sb 2 o 3 , 4.99% Fe 2 o 3 , 2.57%TiO 2 , 0.66%Cr 2 o 3 , Other 0.27%. According to the formula, weigh the raw materials, mix them and put them into a crucible, melt them in a silicon-molybdenum rod high-temperature electric furnace at 1500°C for 120 minutes, then lower the temperature to 1400°C for 60 minutes, clarify and homogenize them into glass liquid. The molten gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com