Plasticizer for ceramet production

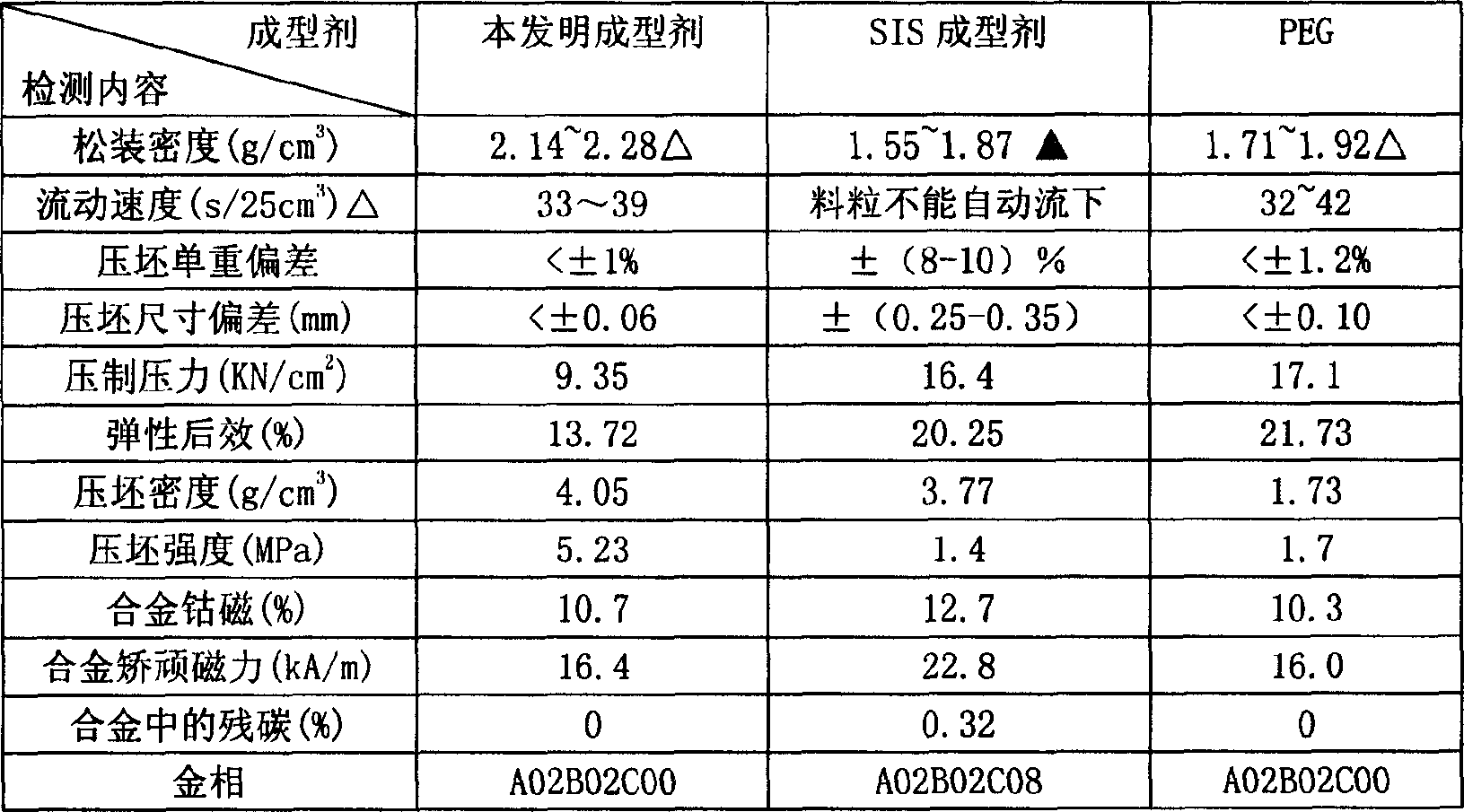

A technology of cermets and molding agents, which is applied in the field of molding agents produced by powder metallurgy, and can solve the problems of low compaction strength, high pressing pressure, and easy dirt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: put into the autoclave together with the polyvinylpyridine of 20% by weight, the polyethylene glycol of 38%, the stearic acid of 2% and the dehydrated alcohol of 40%, be heated to about 50 ℃, and Stirring and blending to form a uniform solution, that is, to obtain the forming agent of the present invention, which is used for the production of ultrafine Ti(CN)-based cermets.

Embodiment 2

[0014] Embodiment 2: be that 40% polyvinylpyridine, 20% polyethylene glycol, 10% stearic acid and 40% dehydrated alcohol are put into autoclave together by weight percentage, be heated to about 50 ℃, and Stir and blend to form a uniform solution, that is, to obtain the forming agent of the present invention, which is suitable for the production of complex-shaped cermet products.

Embodiment 3

[0015] Embodiment 3: be that 24% polyvinylpyridine, 10% polyethylene glycol, 6% stearic acid and 60% dehydrated alcohol are put into autoclave together by weight percentage, are heated to about 50 ℃, and Stir and blend to form a homogeneous solution, that is, to obtain the molding agent of the present invention, which is suitable for the production of micron-based cermets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com