Method for preparing near-infrared light-emitting ZnO film doped with lithium and erbium

A near-infrared and thin-film technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of near-infrared luminescent ZnO thin film preparation and very little research on photoelectric properties, and achieve good surface morphology, high crystal quality, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

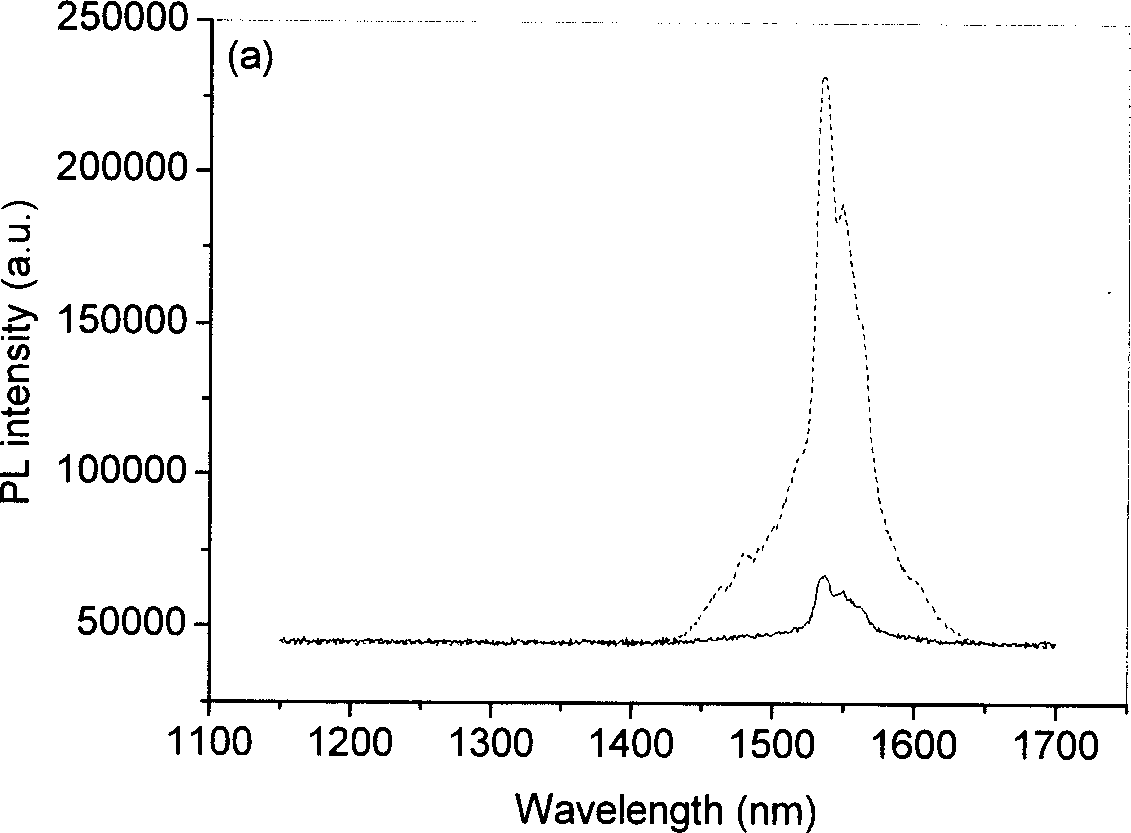

Image

Examples

Embodiment 1

[0019] 1) Take 25.0g (0.307mol) of ZnO powder with a purity of 99.99%, 1.5480g (0.00808mol) of Er with a purity of 99.99% 2 o 3 powder and 0.2994 g (0.00808 mol) of Li with a purity of 99.9% 2 CO 3 Powder, mixed with alcohol in a milling jar and milled with agate balls for 24 hours. After drying, put it into a silicon carbide rod furnace and pre-fire it at 800°C for 1 hour, and then put it into a ceramic mortar and grind it with a binder for 1 hour. Then put it into a mold and press it into a disc with a diameter of about 5 cm and a thickness of about 2 mm. Put the wafer into a silicon carbide rod furnace and sinter at 1200°C for 2 hours to make a ceramic target.

[0020] 2) Put the ceramic target prepared above into the growth chamber of the pulsed laser deposition device, adjust the growth parameters as follows: laser energy 336mJ, frequency 3Hz, distance between target and Si(111) substrate 4.5cm, oxygen pressure 1Pa, The substrate was heated to 750° C. and the growth ...

Embodiment 2

[0024] 1) Take 25.0g (0.307mol) of ZnO powder with a purity of 99.99%, 0.587g (0.00310mol) of Er with a purity of 99.99% 2 o 3 powder and 0.114 g (0.00310 mol) of Li with a purity of 99.9% 2 CO 3 Powder, mixed with alcohol in a ball mill jar and milled with agate balls for 24 hours. After drying, put it into a silicon carbide rod furnace and pre-fire it at 900°C for 1 hour, and then put it into a ceramic mortar and grind it with a binder for 1 hour. Then put it into a mold and press it into a disc with a diameter of about 5 cm and a thickness of about 2 mm. Put the wafer into a silicon carbide rod furnace and sinter at 1500°C for 2 hours to make a ceramic target.

[0025] 2) Put the ceramic target prepared above into the growth chamber of the pulsed laser deposition device, adjust the growth parameters as follows: laser energy 336mJ, frequency 3Hz, target and SiO 2 / Si substrate distance 4.5cm, oxygen pressure 0.1Pa, substrate heating to 550°C, growth time 45min, to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com