Preparation technology of black sulfide dye and its product

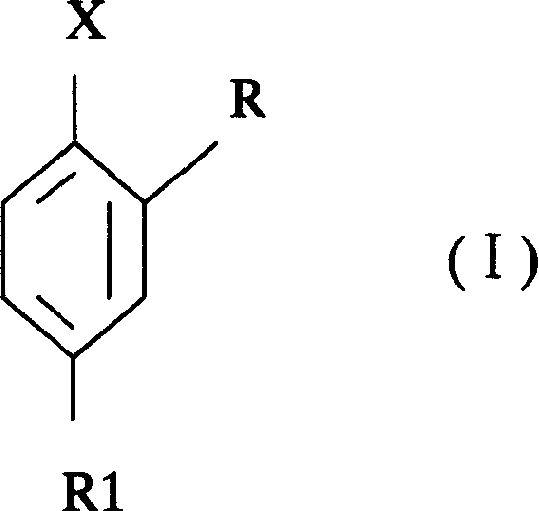

A technology for sulfur black and dyes, which is applied in the direction of azo dyes, organic dyes, nitro/nitroso dyes, etc. It can solve the problems of uneven water content of dyes, reduce dye yield, pollute the environment, etc., and achieve good fluidity , Superior application performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] a. Preparation of sodium polysulfide: add 150 parts of water to a 500ml three-neck flask, heat up to 80°C, add 150 parts of 60% sodium sulfide, stir until all of it dissolves, add 105 parts of sulfur, after adding, keep warm at 98°C for reaction 2 hours to spare.

[0038] b. Hydrolysis: Add 100 parts of water and 150 parts of 2,4-nitrochlorobenzene into a 500ml three-neck flask, add dropwise 210 parts of 30% caustic soda solution at 70°C, keep the reaction at 100°C for 1 hour, and set aside.

[0039] c. Vulcanization: Add the prepared hydrolyzed material and sodium polysulfide solution in a 1000ml autoclave, react at 100°C for 1 hour, then seal the pot cover, heat up to 140°C, react at 120°C for 7 hours, and control the reaction pressure at 0.1Mpa, after the reaction is completed, exhaust, and the discharged hydrogen sulfide gas is recovered into sodium sulfide with 30% caustic soda.

[0040] d. Oxidation and filtration: Put the vulcanized material into a 2000ml beaker...

Embodiment 2

[0044] a. Preparation of sodium polysulfide: add 150 parts of water to a 500ml three-neck flask, heat up to 85°C, add 150 parts of 60% sodium sulfide, stir until all of it dissolves, add 105 parts of sulfur, after adding, keep warm at 99°C for reaction 2 hours to spare.

[0045] b. Hydrolysis: Add 100 parts of water and 150 parts of 2,4-nitrochlorobenzene into a 500ml three-neck flask, add dropwise 210 parts of 30% caustic soda solution at 80°C, keep the reaction at 102°C for 1 hour, and set aside.

[0046] c. Vulcanization: Add the prepared hydrolyzed material and sodium polysulfide solution in a 1000ml autoclave, react at 100°C for 1 hour, then seal the pot cover, heat up to 140°C, react at 130°C for 7 hours, and control the reaction pressure at 0.12Mp, after the reaction is completed, exhaust, and the discharged hydrogen sulfide gas is recovered into sodium sulfide with 30% caustic soda.

[0047] d. Oxidation and filtration: Put the vulcanized material into a 2000ml beaker...

Embodiment 3

[0051] a. Preparation of sodium polysulfide: add 150 parts of water to a 500ml three-necked flask, raise the temperature to 90°C, add 150 parts of 60% sodium sulfide, stir until completely dissolved, add 105 parts of sulfur, after adding, keep warm at 100°C for reaction 2 hours to spare.

[0052] b. Hydrolysis: Add 100 parts of water and 150 parts of 2,4-nitrochlorobenzene into a 500ml three-neck flask, add dropwise 210 parts of 30% caustic soda solution at 90°C, keep the reaction at 105°C for 1 hour, and set aside.

[0053] c. Vulcanization: Add the prepared hydrolyzed material and sodium polysulfide solution in a 1000ml autoclave, react at 100°C for 1 hour, then seal the pot cover, heat up to 140°C, react at 140°C for 7 hours, and control the reaction pressure at 0.13Mp, after the reaction is completed, exhaust, and the discharged hydrogen sulfide gas is recovered into sodium sulfide with 30% caustic soda.

[0054] d. Oxidation and filtration: Put the vulcanized material in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com