Plasma treatment apparatus and method

A plasma and equipment technology, applied in the field of fiber materials, which can solve problems such as economical infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

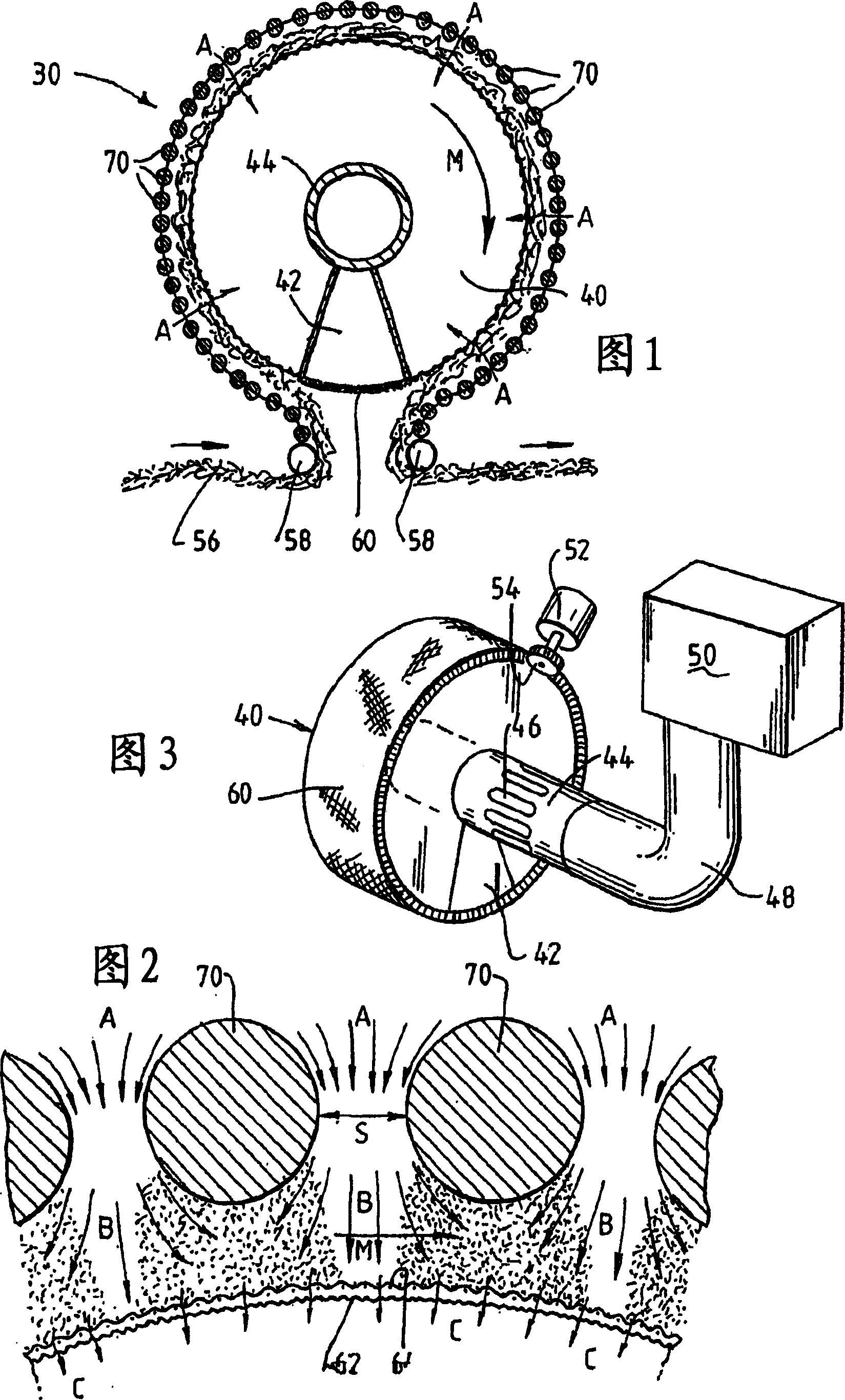

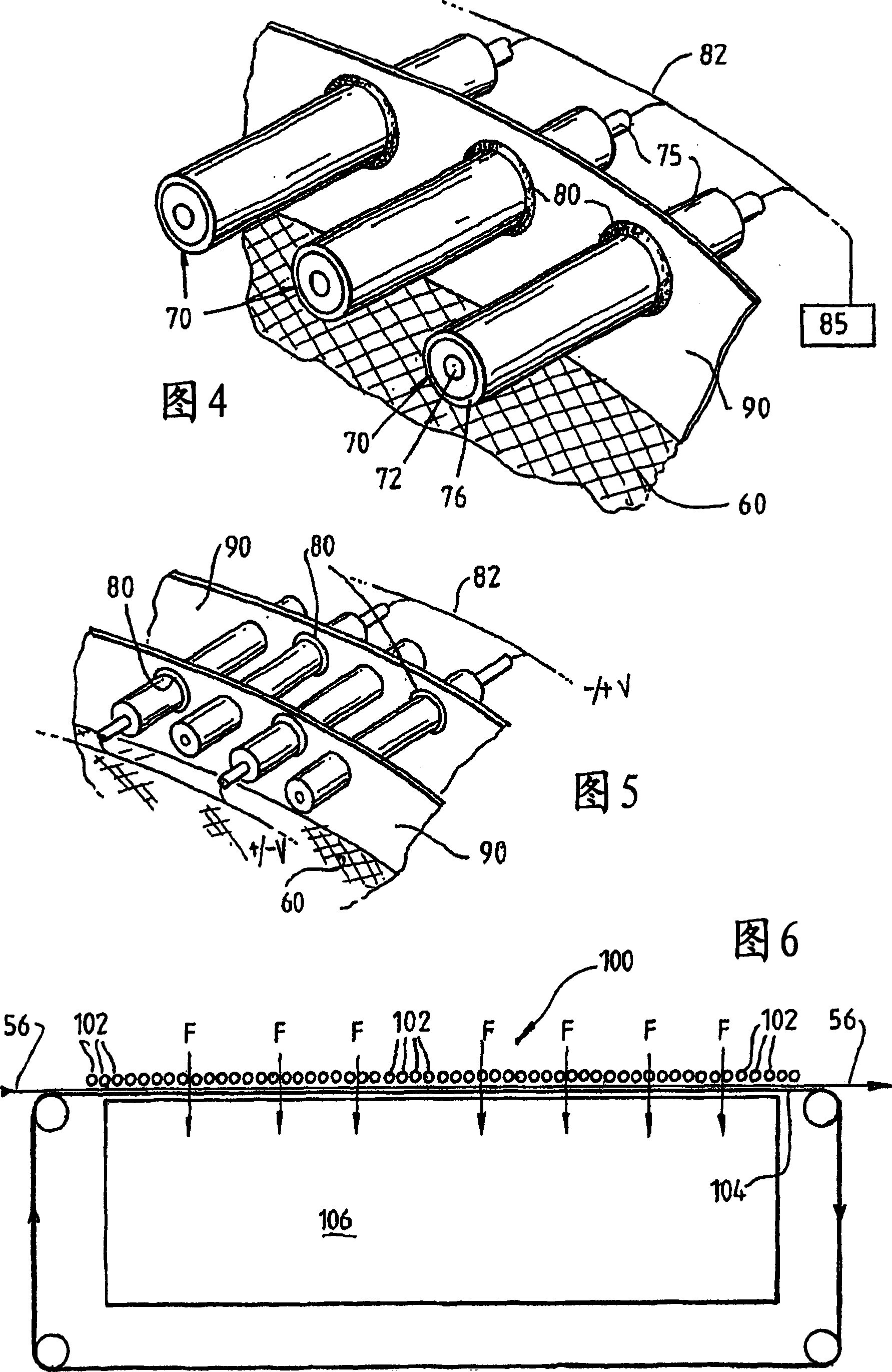

[0055] Referring first to Figures 1 and 2, it can be seen that the plasma processing apparatus 30 includes a hollow, rotatable drum 40 having a first electrode formed on the curved outer surface of the drum 40 in the form of a mesh electrode 60 thereon. The device 30 further includes a second electrode formed as a plurality of rod electrodes 70 spaced radially outward from the mesh electrode 60 .

[0056] The mesh electrode 60 includes a coarse mesh 62 that supports an overlying fine mesh 64 . The fine mesh 64 prevents the localization of the plasma microdischarge by providing a large array of potential plasma formation sites, where a reduced number of potential plasma formation locations will generally result in plasma microdischarge compared to the coarse mesh 62. Electrical localization.

[0057] As shown in FIGS. 1 and 3 , the drum 40 has a tubular core 44 and wedge-shaped baffles 42 extending from the core to the periphery of the drum 40 . The core 44 extends through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com