Clad pipe

A composite pipe and alloy steel pipe technology, applied in the structural field of composite pipes, can solve the problems of pipe bending, high cost, no clear boundary between the base material and the solder layer, etc., and achieves the effects of easy welding and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0218] As the outer layer steel pipe, STKM13A carbon steel pipe for machine structure with the following specifications was used.

[0219] The chemical composition of STKM13A carbon steel pipe for mechanical construction is:

[0220] C: ≤0.20% Si: ≤0.35% Mn: ≤0.60%

[0221] P: ≤0.04% S: ≤0.04%.

[0222] The outer layer steel pipe was processed to have an outer diameter of 315mmφ, an inner diameter of 275mmφ, and a length of 2000mm.

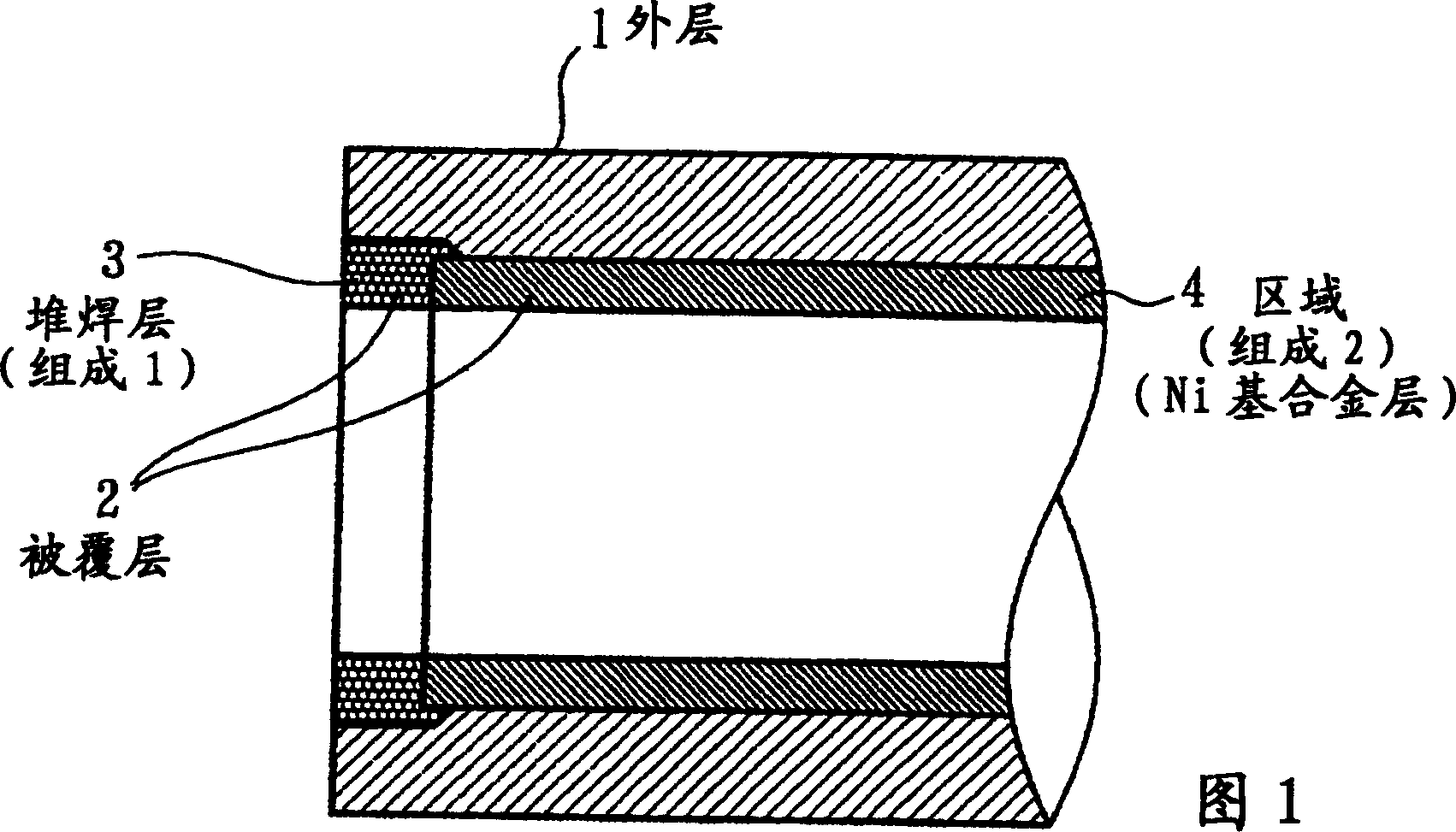

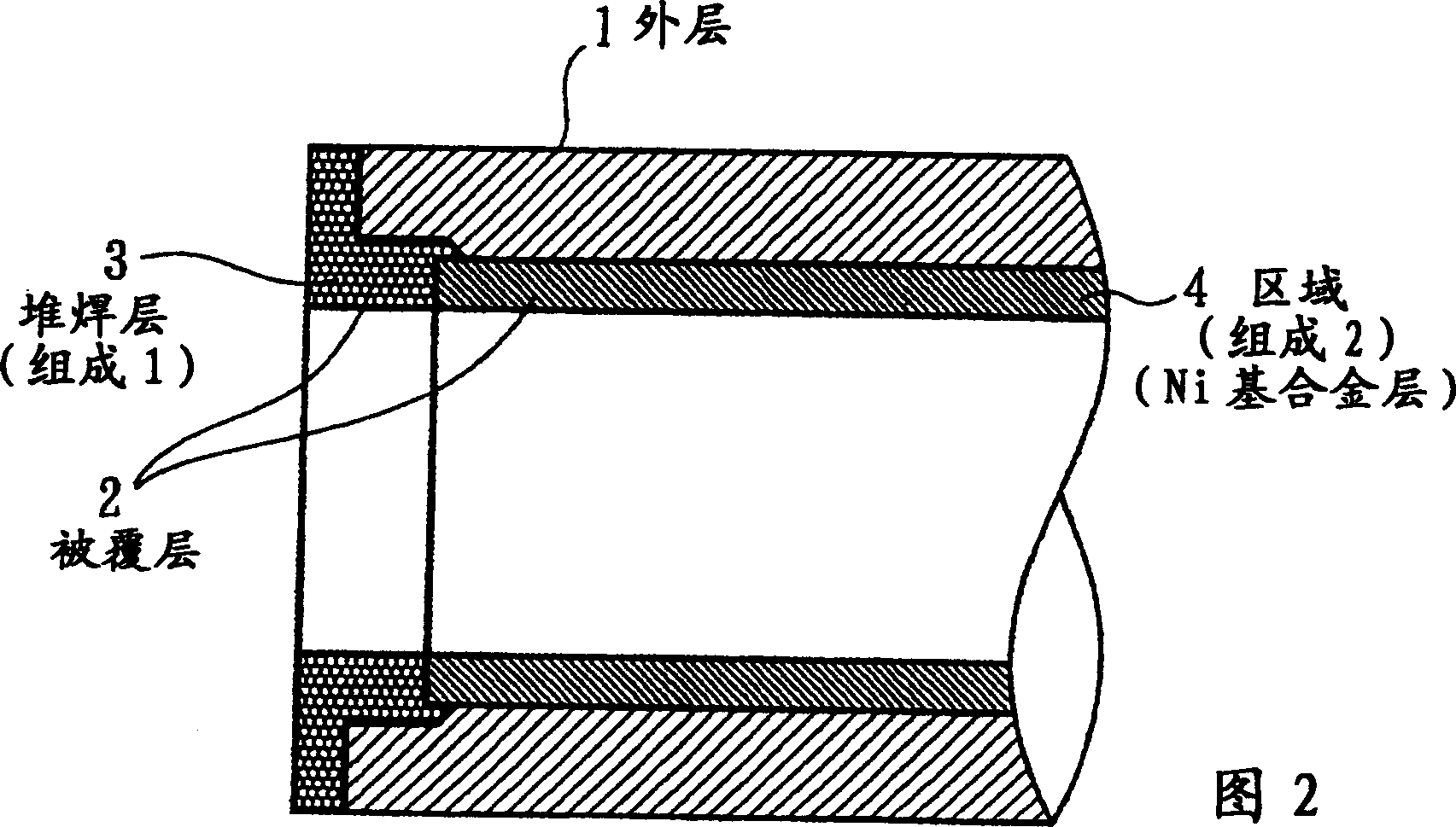

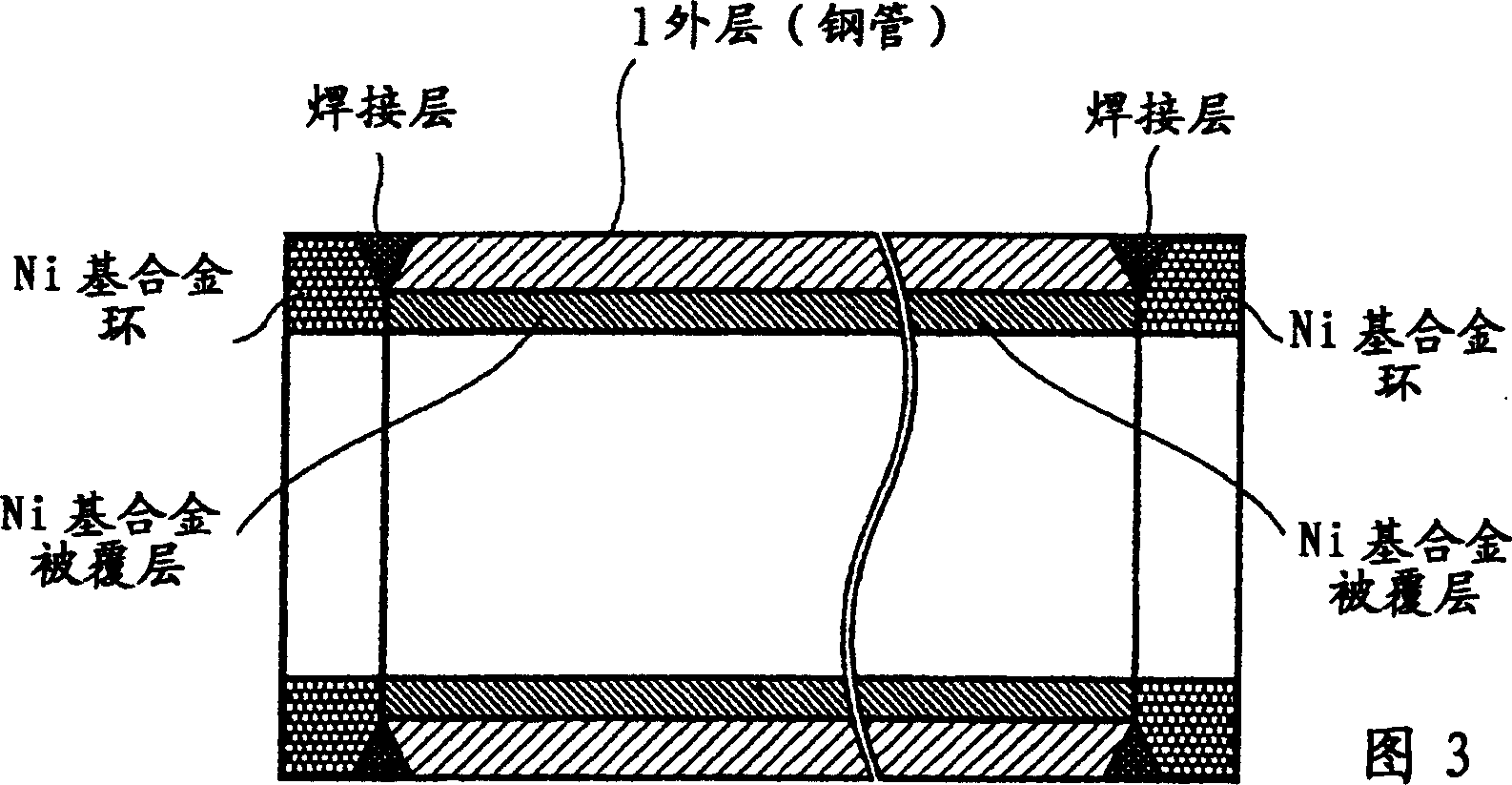

[0223] Machine the inner end into Image 6 In that way, a Ni-based alloy equivalent to inconel 625 is surfacing. After surfacing, machining into Figure 7 That way (thickness of the solder layer: 6mm).

[0224] The tube was laid down horizontally, and the whole was induction-heated to 1050°C, and a molten liquid having the following composition was poured into the tube while rotating.

[0225] The chemical composition of the melt is:

[0226] Cr: 18% C: 0.8% B: 3.5%

[0227] Si: 4.0% the rest is Ni and impurities

[0228]The injection tem...

Embodiment 2

[0238] Corrosion Test 1 (Example of Alloy 1)

[0239] Ni-based alloys with different composition were left for 48 hours in a humidified hydrogen sulfide flowing atmosphere, and the weight change (increase) was investigated to conduct a comparative test of corrosion resistance.

[0240] Sample size: 20×20×5mm

[0241] Flow rate of hydrogen sulfide: 100ml / min

[0242] Time: 48 hours

[0243] Temperature: room temperature

[0244] Table 1 shows the composition of the Ni-based alloy (alloy 1) and the measurement results of the corrosion gain.

[0245] Table 1

[0246] serial number

Cr

B

Si

C

Fe, Co

Mo

Nb

Ni

Remark

1

15

3.2

4.4

0.7

Fe3.5

the remaining

5.210

2

18

3.5

4.0

0.3

Co3.0

16

the remaining

1.680

3

15

3.1

4.3

0.8

Fe3.5

the remaining

...

Embodiment 3

[0252] Corrosion Test 2 (Example of Alloy 2)

[0253] Ni-based alloys with different composition were left for 48 hours in a humidified hydrogen sulfide flowing atmosphere, and the weight change (increase) was investigated to conduct a comparative test of corrosion resistance.

[0254] Sample size: 20×20×5mm

[0255] Hydrogen sulfide flow rate: 100ml / min

[0256] Time: 48 hours

[0257] Temperature: room temperature

[0258] Table 2 shows the composition of the Ni-based alloy (alloy 2) and the measurement results of corrosion increment.

[0259] Table 2

[0260] serial number

B

Si

C

Fe, Co

Mo

Nb

Al

Cu

Cr

Ni

weight change

1

5.0

3.0

0.1

4

the remaining

1.02

2

3.0

6.0

0.1

the remaining

0.95

3

4.0

9.0

0.1

0.1

the remaining

0.97

4

2.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com