Warm-up flash two-purpose nano impression device

A nano-imprinting, dual-purpose technology, applied in the direction of photolithography process exposure device, micro-structure device, manufacturing micro-structure device, etc. And the effect of strong practicability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

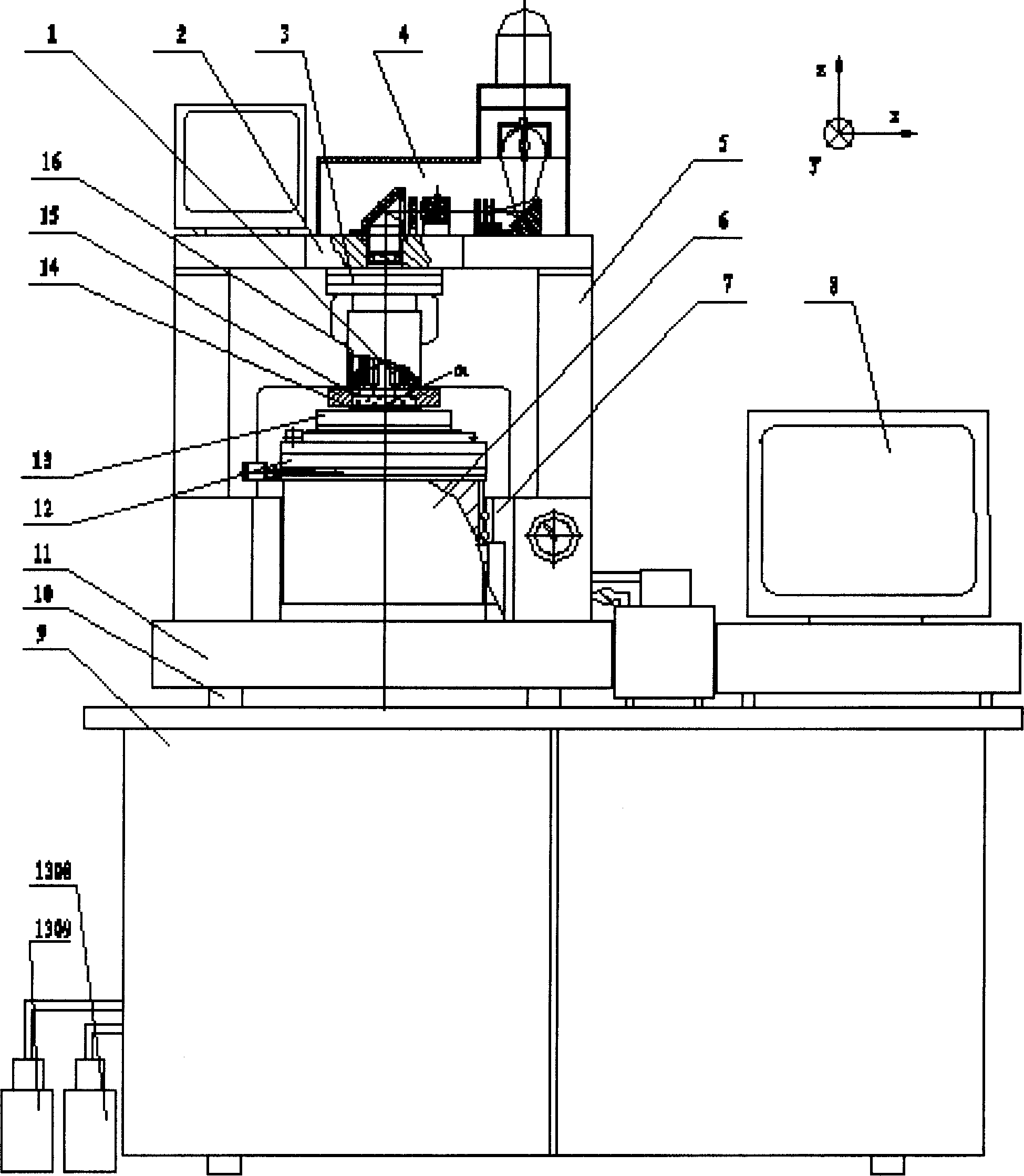

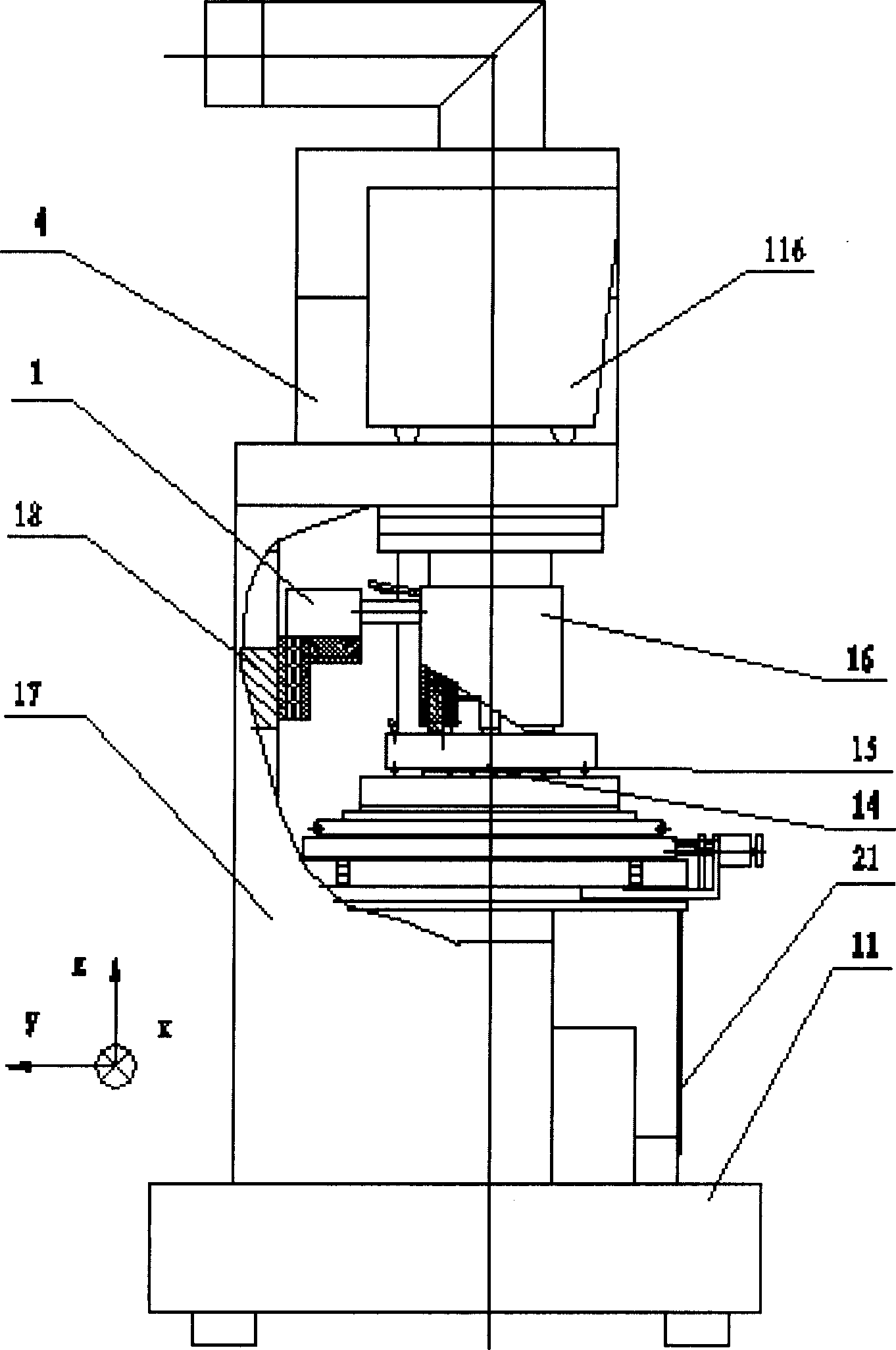

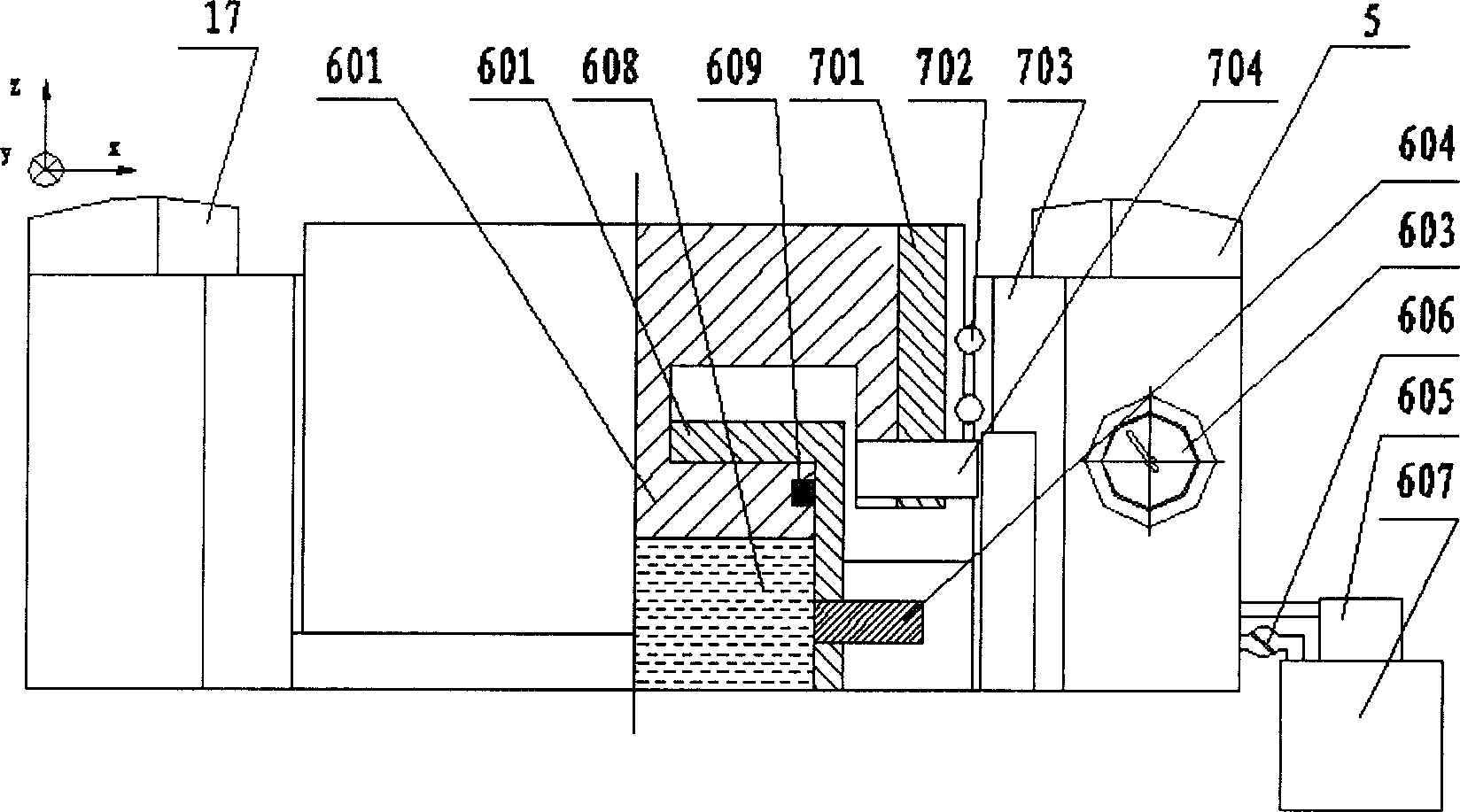

[0034] Such as figure 1 , 2 As shown, the embodiment of the present invention consists of a dual-channel CCD alignment system 1, a horizontal plate 2, a Z-direction corrector 3, a purple light illumination system 4, a left side plate 5, a right side plate 17, a rear plate 18, and an oil pressure jacking system 6 , Z-direction linear guide rail mechanism 7, computer system 8, machine cabinet 9, main machine base plate 11, XYθ micro-motion workpiece table 12, substrate heating table 13, substrate 14, die 15, tilt calibration mechanism 16 and control system 20 and other parts. The large base plate 11 of the main machine is placed on the table top of the machine cabinet 9 through the vibration isolation pad 10, and the electrical control system 20 placed in the machine cabinet 9 has an embossing control 201, a CCD image and A / D conversion circuit 202, and an XYθ micro-motion workpiece The measurement drive control circuit 203, constant light intensity and integral shutter contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com