Device for measuring reaction rateof flash magnetized calcination for refractory iron oxide ore

A technology of flash magnetization roasting and testing device, which is applied in measurement devices, soil material testing, preparation of test samples, etc., can solve the problem of separation of hematite and gangue minerals, high energy consumption and cost, and material magnetization roasting time long-term issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

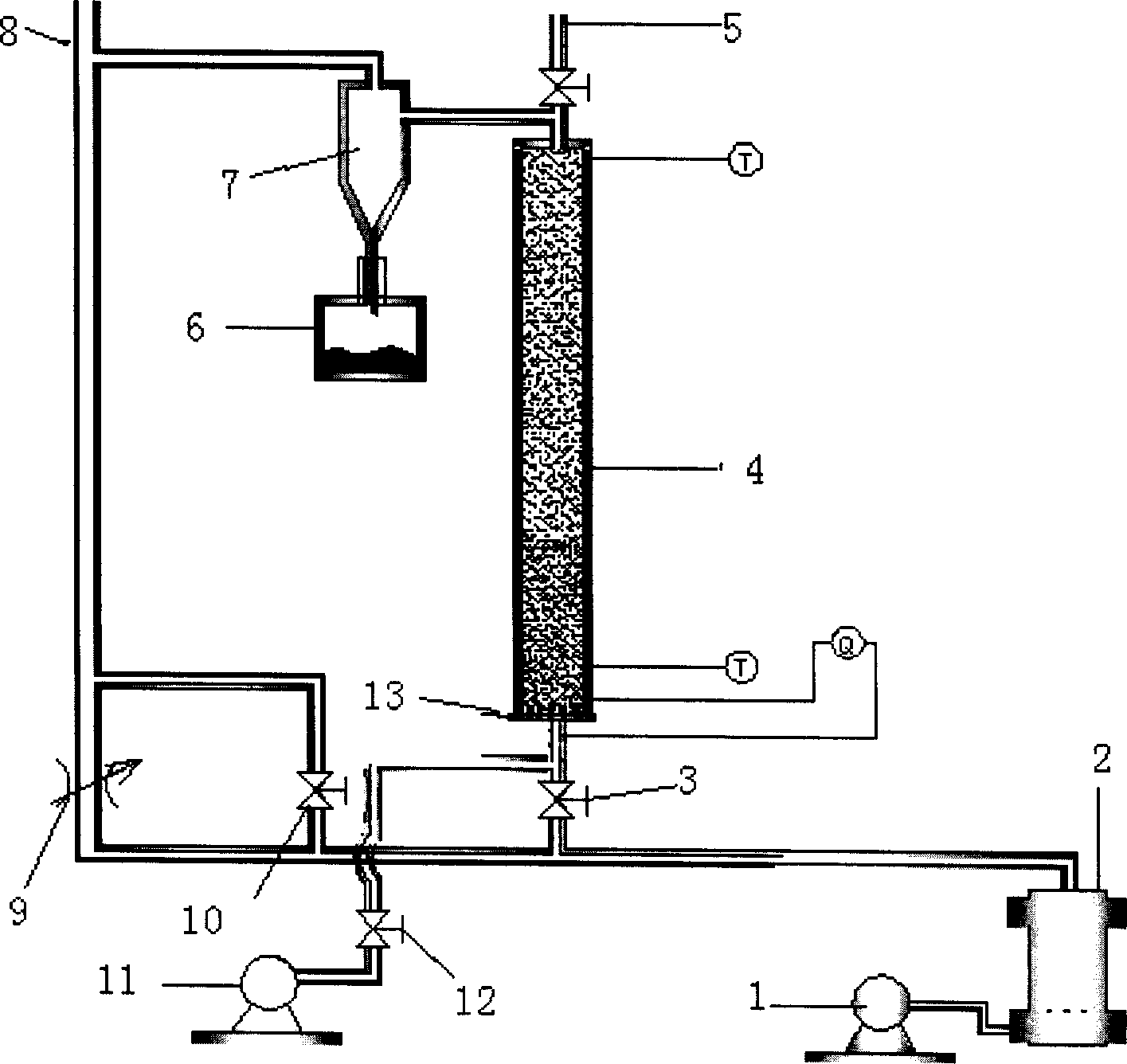

[0012] The invention is an industrial test device for fluidizing and roasting hematite into magnetite by using reducing gas under high temperature conditions.

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0014] The structure of the present invention is as shown in the figure: a blower fan 1, a gas generator 2, a separator 7 and a reaction furnace 4 connected through pipelines are provided in sequence. A regulating valve 9 and a switching valve 10 are provided on the pipeline connecting the gasifier 2 and the separator 7 , and a material receiving device 6 is provided at the lower part of the separator 7 . A communicating pipeline is provided between the gas generator 2 and the reaction furnace 4, and a switching valve 3 is provided on the pipeline. The bottom of the reaction furnace 4 communicates with the fan 11 through a pipeline, and a control valve 12 is arranged on the pipeline. The switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com