Prepn of photocatalytic titania fiber material

A functional material, titanium dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low strength of titanium dioxide fiber, complicated spinning solution preparation process, and practical application limitations of fibers, etc. Achieve high strength, high porosity, easy operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation method of titanium dioxide short fiber adopts the following steps

[0038] 1. Synthesis of polyethylacetoacetate titanium precursor. According to the ratio of tetrabutyl titanate: distilled water: ethyl acetoacetate = 1mol: 1.5mol: 0.5mol, measure 34ml, 2.7ml, 6.4ml of the above three liquid reagents (analytical grade) respectively, and dilute them in two parts respectively. In isopropanol, dilute tetrabutyl titanate and ethyl acetoacetate in the same part of isopropanol, wherein the volume dilution factor of tetrabutyl titanate is 3 times, and at room temperature, dilute tetrabutyl titanate Mixed and stirred with ethyl acetoacetate diluent in isopropanol for 60 min to obtain mixed diluent A. Dilute the distilled water in another part of isopropanol, and the volume dilution factor is 20-30 times to obtain the mixed dilution B. Then, under the condition of stirring and 0℃~40℃, add the mixed diluent B or A dropwise into the mixed diluent A ...

Embodiment 2

[0043] Embodiment 2: the preparation method of titanium dioxide porous short fiber

[0044] As described in Example 1, the difference is that the heating program in step 4 is changed as follows: the heating rate at 25°C to 95°C is 100°C / h, and the temperature is kept at 95°C for 24 hours, and the heating rate at 95°C to 250°C is The heating rate is 200℃ / h, the heating rate is 50℃ / h at 250℃~350℃, the heating rate is 300℃ / h at 350℃~550℃, the heating rate is 50℃ / h at 550℃~650℃, and the heating rate is 50℃ / h at 650℃~700℃ The heating rate is 300°C / h, and the temperature is kept at 700°C for 1 hour, and the temperature is naturally lowered. Obtain a tensile strength of 100MPa~1.2Gpa, a diameter of 10μm~25μm, a continuous length of monofilament of 5cm~50cm, and a BET specific surface area of 250m 2 Titanium dioxide porous short fiber with / g, pore diameter of 5nm-10nm, grain size of 10nm-30nm, crystal phase of anatase phase.

Embodiment 3

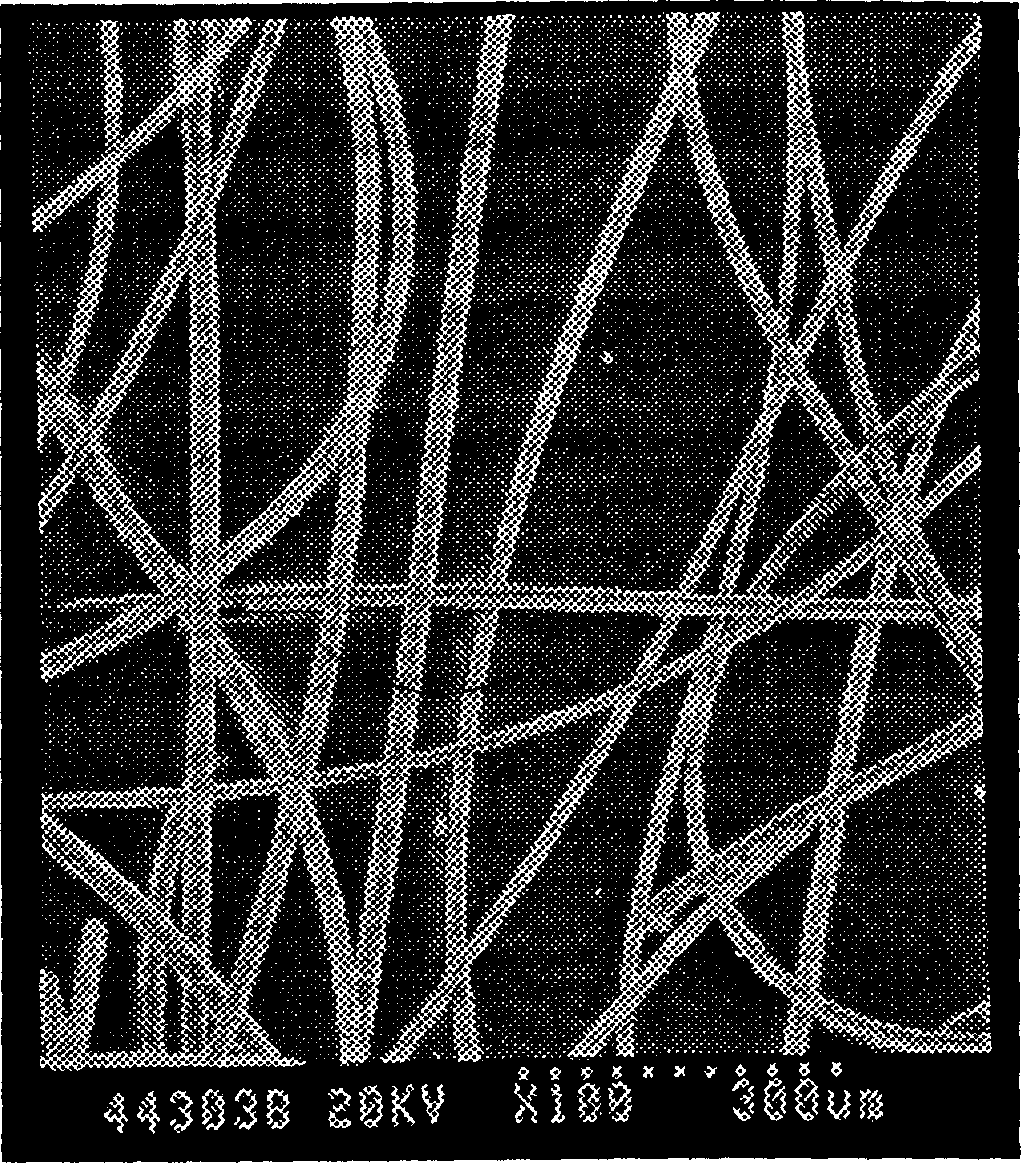

[0045] Embodiment 3: the preparation method of titanium dioxide continuous fiber

[0046] As described in Example 1, the difference is that the solution is concentrated by evaporating the solvent in step 2 so that the viscosity of the spinning solution reaches 75 Pa·s, and the spinning method in step 3 is changed to dry spinning. Move the spinning solution into the liquid material tank in the dry spinning device, vacuum defoam for 10 minutes, and apply a pressure of 2.0 MPa to the spinning solution under the condition of a temperature of 25°C and a relative humidity of 40%, so that it can be removed from a hole diameter of 0.15 The mm niobium-tantalum alloy spinning plate is sprayed out, and after drafting and drum collection, the length can be almost arbitrarily long, transparent and orderly continuous precursor long fibers. Such as figure 2 Photos shown. image 3 is its scanning electron microscope (SEM) picture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com