Diamond film containing chronium and its preparing method

A diamond thin film and thin film technology, which is applied in metal material coating technology, ion implantation plating, superimposed layer plating, etc., can solve the problems of poor wear resistance of the film, high film brittleness, and poor bonding force, etc., to achieve Effects of improved performance, high hardness, and enhanced sputtering effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Coating device

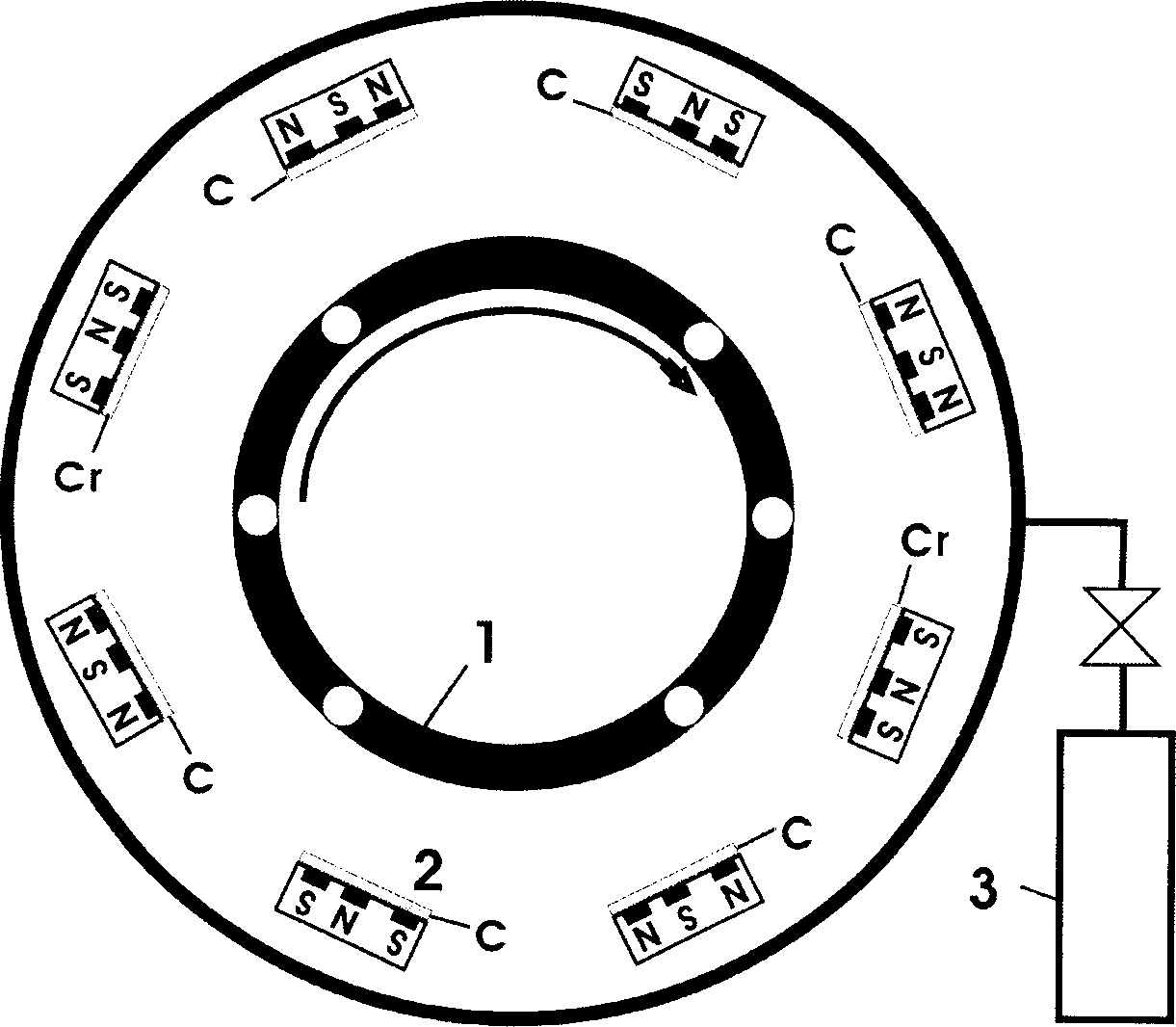

[0030] Using SP8050 coating machine (manufactured by Beijing Shiliyuan Science and Technology Co., Ltd.) to synthesize chromium-containing hydrogen-free DLC film by unbalanced magnetron sputtering method, the cross-sectional schematic diagram of the coating machine is as follows figure 1 As shown, four pairs of magnetron targets are placed in a cylindrical vacuum chamber, including two Cr targets and six C targets, and the C targets are graphite targets. The specification of the target is 420mm×8mm, and the purity is 99.99%. The two planar magnetron targets of each pair of magnetron targets are arranged face to face with an interval of 70 cm in the vacuum chamber. The workpiece holder is placed in the central area of the vacuum chamber. A pulsed DC power supply applied to the workpiece to be deposited and four 40kHz pulsed medium-frequency AC power supplies applied to each pair of targets are used to control the negative bias voltage of the subst...

Embodiment 2

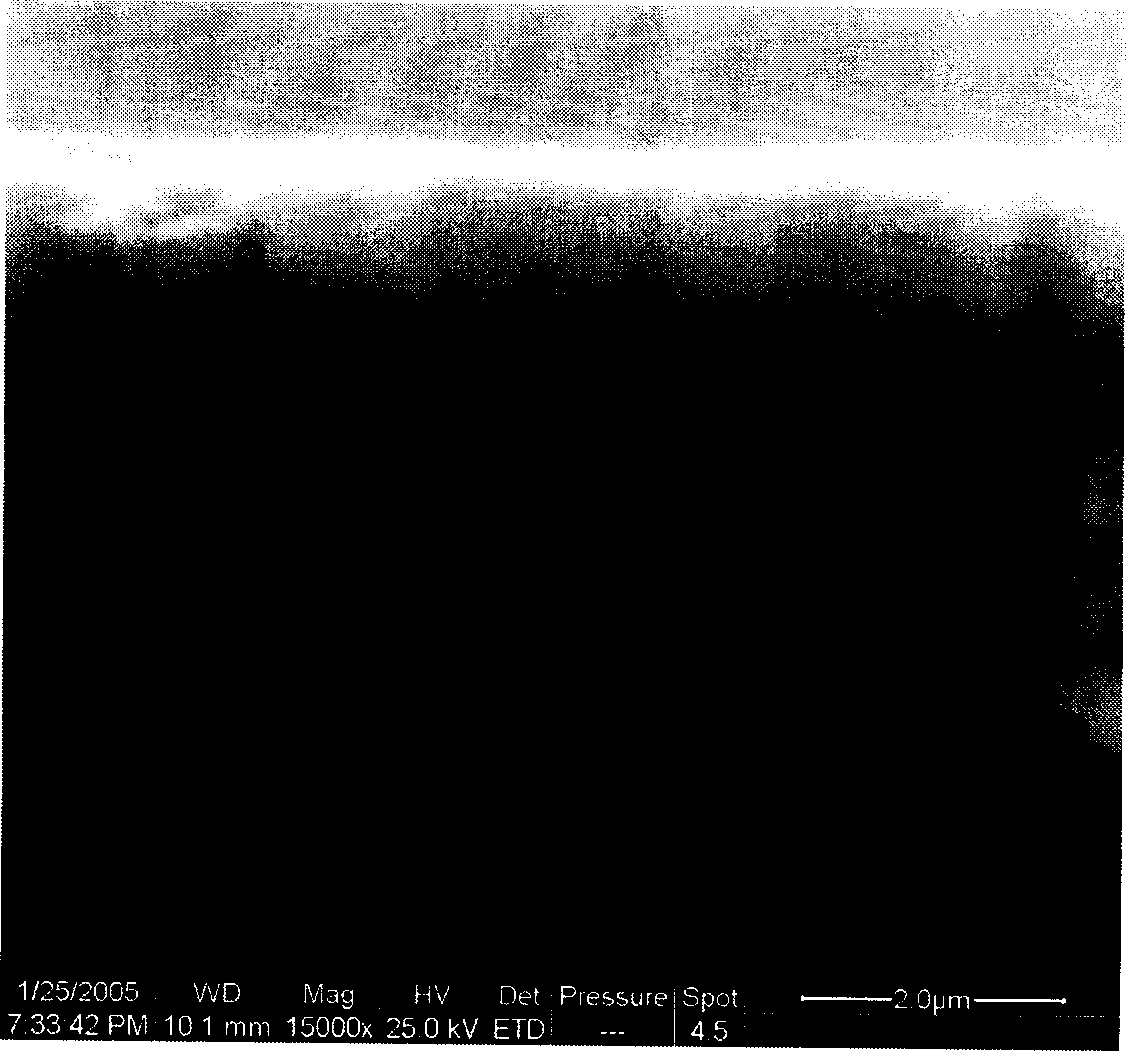

[0046] The film has a three-layer structure, from the surface of the substrate to the outside: Cr layer: 0.25μm; CrN 0.1 Layer: 0.45μm; Cr 0.1 Layer C: 1.45 μm.

Embodiment 3

[0048] The film has a six-layer structure, from the surface of the substrate to the outside: Cr layer: 0.20μm; CrN 0.6 Layer: 0.40μm; Cr 0.55 C 0.1 Layer: 0.85μm; Cr layer: 0.25μm; CrN 0.6 Layer: 0.45μm; Cr 0.55 C 0.1 Layer: 0.80μm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com