Prepn process of high temperature superconductive Ni-W alloy

A high-temperature superconducting and alloying technology, applied in the field of polycrystalline textured Ni-W baseband preparation, to achieve uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

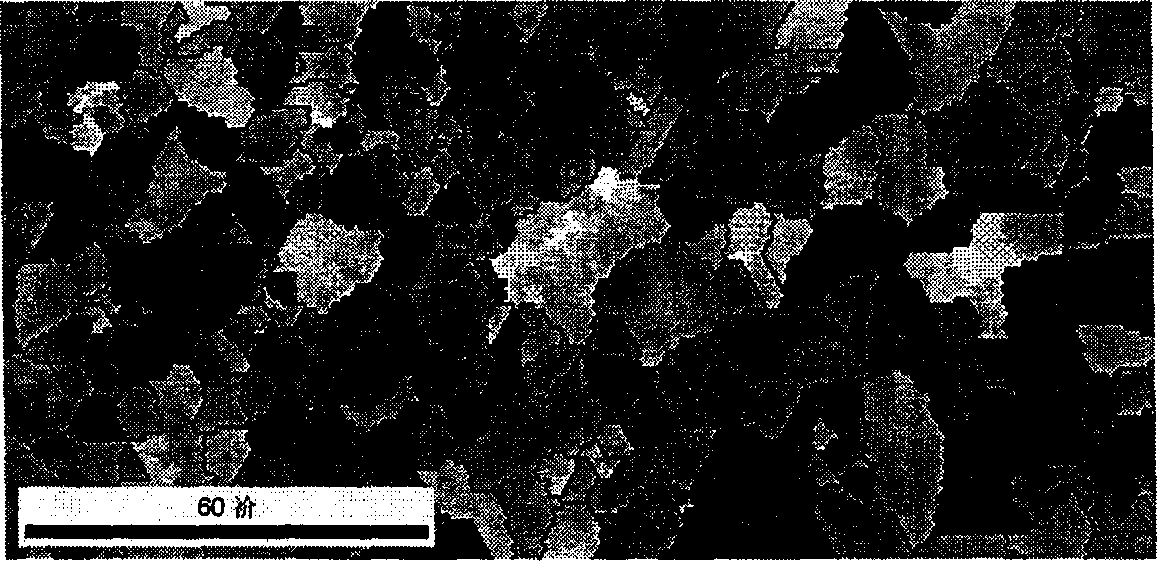

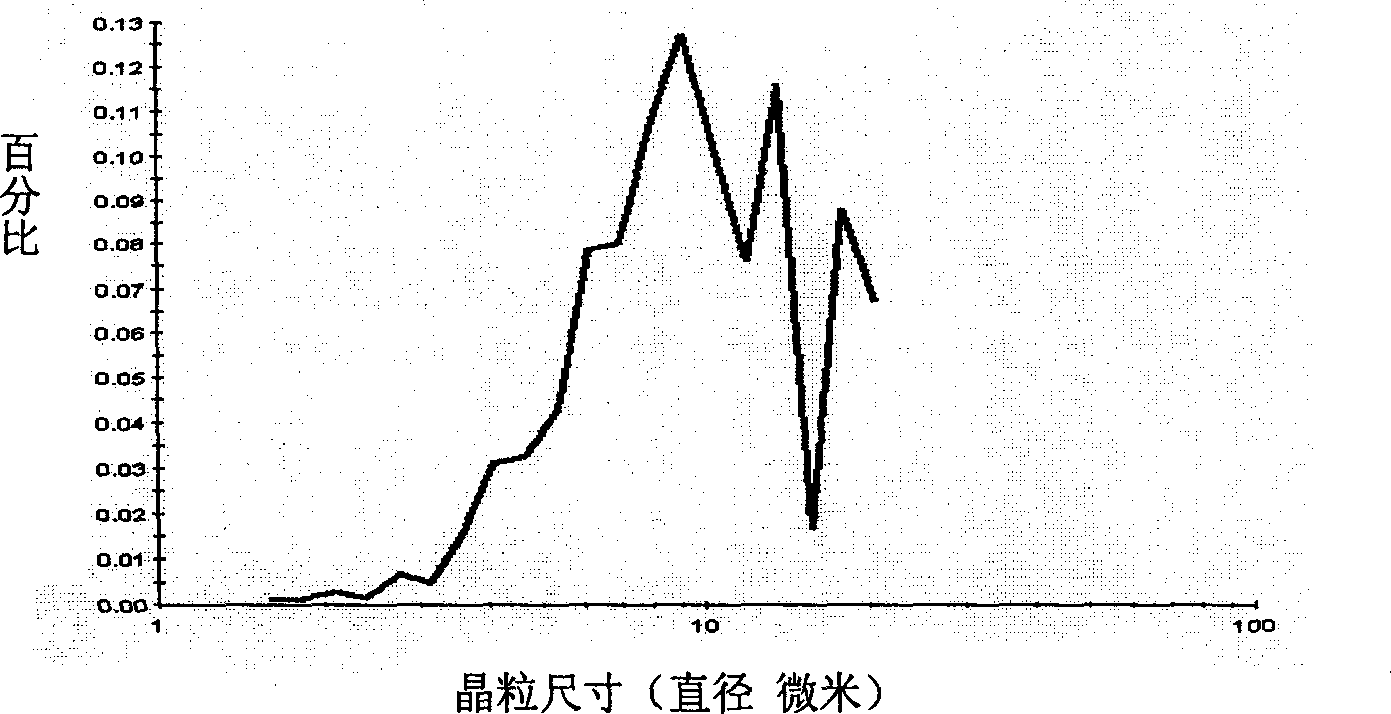

[0027] Example 1. adopt Ni powder and W powder as raw materials, the purity is 99.9% by weight, the Ni powder particle size is 4~6 microns, the W powder particle size is 3~4 microns, and W accounts for 3% atomic percent of composition in the alloy. After mixing evenly, put it into a mold for SPS sintering. The sintering temperature is 800° C., and the sintering holding time is 10 minutes. The sintering pressure is 80MPa. A Ni-3%W block with a density of 98% was obtained. figure 1 It is its backscattered electron diffraction (EBSD) diagram, which shows that the grain size is relatively uniform. figure 2 It is the grain distribution data calculated from the EBSD result, and the data shows that the average grain size of the sample is about 10 microns, and the grains are fine. The results of energy spectrum test show that the distribution of W in the alloy is very uniform.

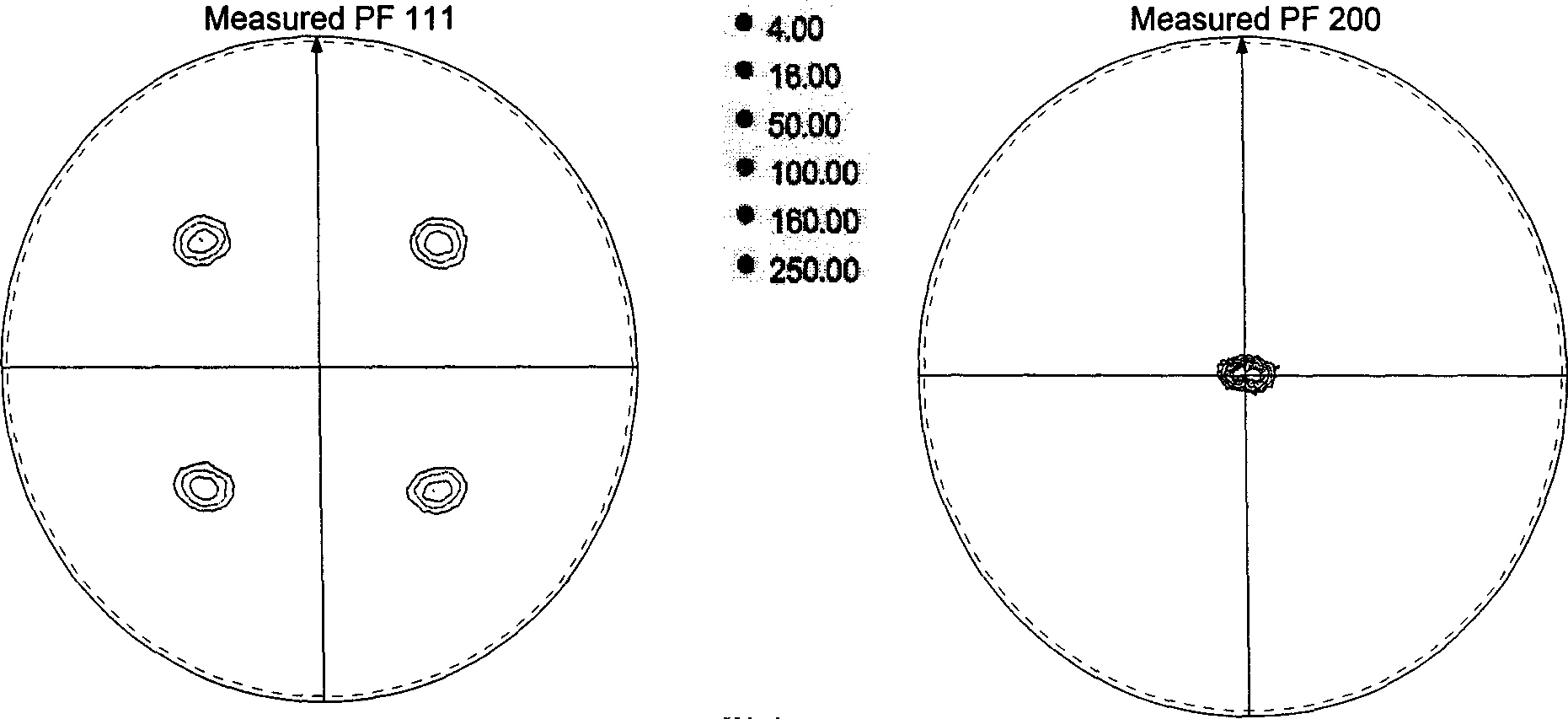

[0028] Cold rolling and recrystallization annealing are carried out on the Ni-3%W block at room temper...

example 2

[0029] Example 2. adopt Ni powder and W powder as raw materials, the purity is 99.99% by weight, the particle size of Ni powder is 3-5 microns, the particle size of W powder is 3-5 microns, and W accounts for 5% by atomic percent in the alloy. After mixing evenly, put it into a mold for SPS sintering. The sintering temperature is 1000° C., and the sintering holding time is 5 minutes. The sintering pressure is 50MPa. A Ni-5%W block with a density of 98.5% was obtained. Figure 4 It is the backscattered electron diffraction (EBSD) figure, which shows that the grain size is uniform. Figure 5 It is the grain distribution data calculated from the EBSD result, and the data shows that the average grain size of the sample is about 10 microns, and the grains are fine. The results of energy spectrum test show that the distribution of W in the alloy is very uniform.

[0030] Cold rolling and recrystallization annealing are carried out on the Ni-5% W block at room temperature, the de...

example 3

[0031]Example 3. adopt Ni powder and W powder as raw materials, the purity is 99.9% by weight, the particle size of Ni powder is 4~6 microns, the particle size of W powder is 3~4 microns, and W accounts for 7% of atomic percentage in the alloy. After mixing evenly, put it into a mold for SPS sintering. The sintering temperature was 1200°C, and no sintering heat preservation was carried out. The sintering pressure is 30MPa. A Ni-7%W block with a density of 97.7% was obtained. Figure 8 It is the backscattered electron diffraction (EBSD) figure, which shows that the grain size is uniform. Figure 9 It is the grain distribution data calculated from the EBSD result, and the data shows that the average grain size of the sample is about 6.6 microns, and the grains are fine. The results of energy spectrum test show that the distribution of W in the alloy is very uniform.

[0032] Cold rolling and recrystallization annealing are carried out on the Ni-7%W block at room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com