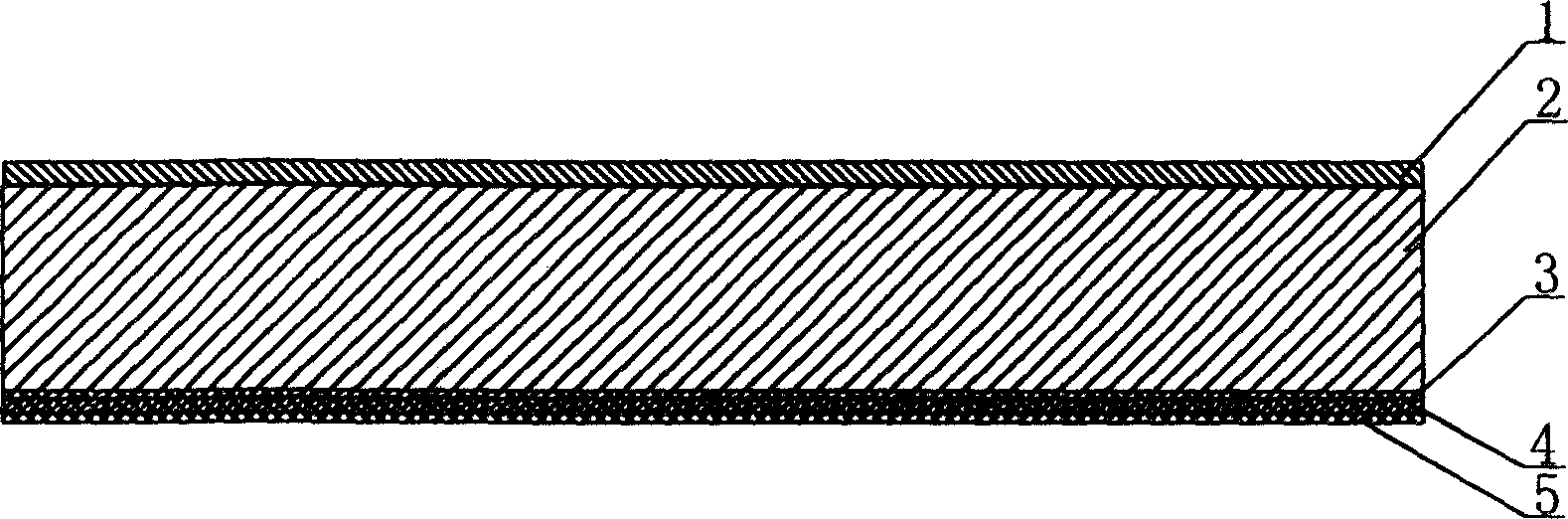

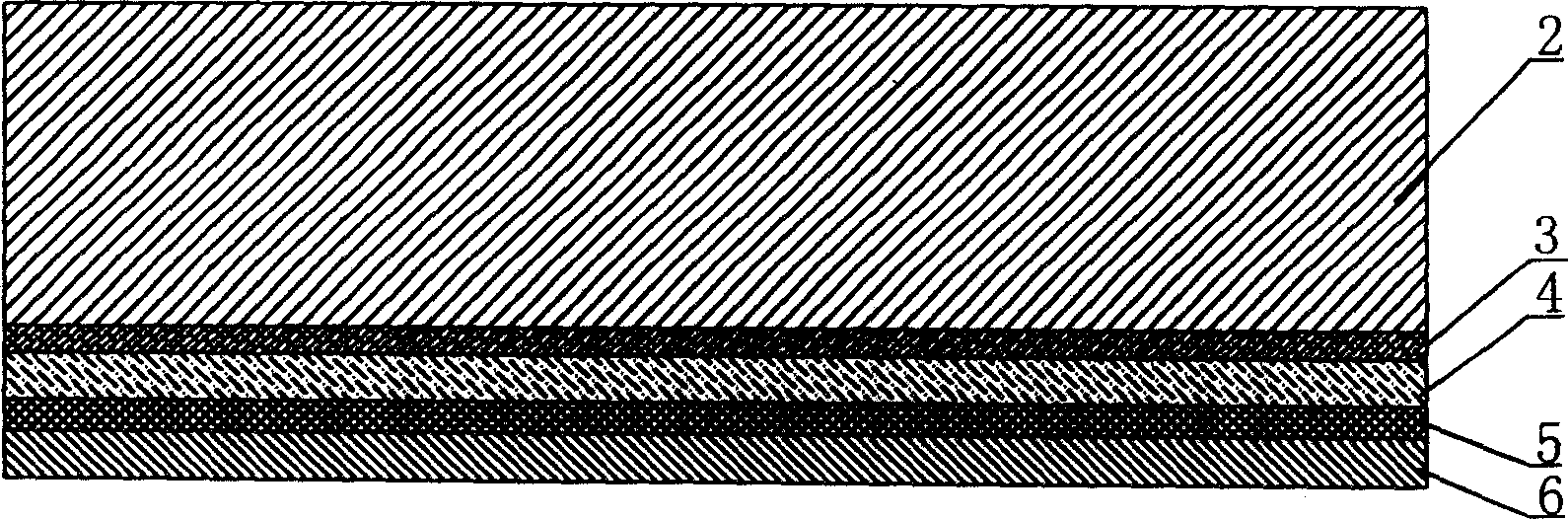

Coloured clad armor plate composite material and adhesive used thereon

A technology for color-coated steel sheets and coated steel sheets, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., to achieve the effects of strong adhesion, cost reduction, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of Adhesive

[0046] Add 20Kg of polyester polyol (PU-1001, produced by Beijing Gaomeng Chemical Co., Ltd.) and 0.5Kg of trimethylolpropane into 20Kg of toluene solvent, add 1.5Kg of diphenylmethane diphenylmethane after dissolving at 60°C Isocyanate and 2.5Kg toluene diisocyanate were reacted for 3 hours to carry out chain extension modification, and the percentage content of detection-NCO was 4.5%, and the temperature was lowered to 40°C, and then 3Kg of methyl methacrylate, 7Kg of hydroxypropyl methacrylate and methyl methacrylate were added. 5Kg of butyl acrylate, 10Kg of ethylene glycol monomethyl ether solvent containing 0.04Kg of benzoyl peroxide and 0.01Kg of cumyl neodecanoate was added at 80°C for 4 hours of reaction. Add 2Kg of p-tert-butylphenol-formaldehyde resin (#2042, produced by Changshu Jiafa Chemical Co., Ltd.), 1.5Kg of terpene resin (produced by Guangdong Deqing Terpene Products Co., Ltd.), bisphenol A epoxy resin (E -44, produced by...

Embodiment 2

[0054] 1. Preparation of Adhesive

[0055] In the toluene solvent of 10Kg, add the trimethylol propane of 25Kg polyester polyol (PU-1001, Beijing Gaomeng Chemical Co., Ltd.) and 1Kg, add 1Kg diphenylmethane diisocyanate and diphenylmethane diisocyanate after dissolving under the condition of 80 ℃ 1Kg of toluene diisocyanate, reacted for 3 hours to carry out chain extension modification, the percentage content of -NCO was detected to be 4.5%, cooled to 40°C, and then added 1Kg of methyl methacrylate, 15Kg of hydroxypropyl methacrylate and butyl methacrylate Add 1Kg of ester to 2Kg of ethylene glycol monomethyl ether solvent containing 0.01Kg of benzoyl peroxide and 0.1Kg of cumyl neodecanoate at 100°C, and react for 4 hours. Add 15Kg of p-tert-butylphenol-formaldehyde resin (#2042, produced by Changshu Jiafa Chemical Co., Ltd.), 1Kg of terpene resin (produced by Guangdong Deqing Terpene Products Co., Ltd.), bisphenol A epoxy resin (E- 44, produced by Changshu Jiafa Chemical Co...

Embodiment 3

[0060] 1. Preparation of Adhesive

[0061] Add 4Kg polyester polyol and 3Kg trimethylolpropane to 5Kg toluene solvent, add 15Kg diphenylmethane diisocyanate and 5Kg toluene diisocyanate after dissolving under the condition of 60°C, react for 3 hours to carry out chain extension modification, Detection-The percentage content of NCO is 4.5%, cool down to 40°C, add 5Kg of methyl methacrylate, 6Kg of hydroxypropyl methacrylate and 15Kg of butyl methacrylate, add 0.005Kg of peroxide at 60°C Benzoyl and 1Kg of ethylene glycol monomethyl ether solvent of 0.05Kg cumyl peroxide neodecanoate were reacted for 4 hours. Add 1Kg of p-tert-butylphenol-formaldehyde resin, 10Kg of terpene resin, 1Kg of bisphenol A epoxy resin, 4Kg of novolac epoxy resin, 15Kg of dioctyl phthalate, 1Kg of ethyl acetate, 10Kg of xylene, and mix well , to obtain the polyurethane adhesive.

[0062] 2. Preparation of color-coated steel composites

[0063] Take a 0.1mm thick polyvinylidene fluoride printed galvan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com