Water-based high-temperature-resistant paint

A high temperature resistant, water-based technology, applied in the field of paint, to achieve the effects of smoke and fire prevention, good adhesion and chemical resistance, and flame isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

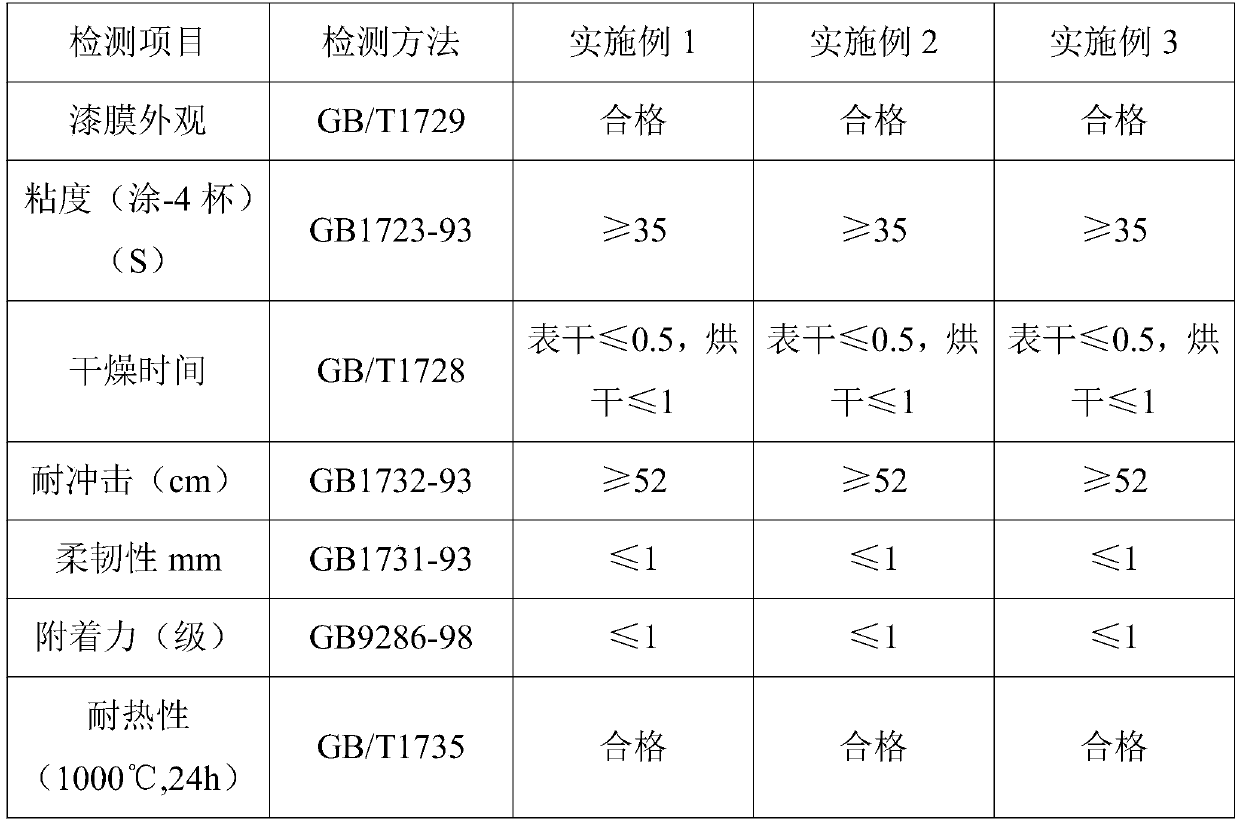

Examples

Embodiment 1

[0019] A water-based high temperature resistant paint, calculated in parts by weight, comprising the following components:

[0020] 45 parts of epoxy modified silicone resin, 20 parts of benzyl silicone resin, 6 parts of crosslinking resin, 12 parts of modified magnesium aluminum hydrotalcite, 4 parts of mica powder, 6 parts of dispersant and 50 parts of water.

[0021] The preparation method of modified magnesium aluminum hydrotalcite comprises the following steps:

[0022] Add magnesium aluminum hydrotalcite and silicon nitride to dimethyl sulfoxide, carry out ultrasonic dispersion to obtain a dispersion liquid, raise the temperature of the dispersion liquid to 80°C, then add KH550 and water in turn, stir and react for 6 hours, cool down to 56°C and then Add diethyl chlorophosphite to react for 5h. The mass ratio of silicon nitride to magnesium aluminum hydrotalcite is 1:7, the mass ratio of KH550 to magnesium aluminum hydrotalcite is 1:23, and the mass ratio of diethyl chl...

Embodiment 2

[0024] A water-based high temperature resistant paint, calculated in parts by weight, comprising the following components:

[0025] 40 parts of epoxy modified silicone resin, 25 parts of benzyl silicone resin, 8 parts of crosslinking resin, 8 parts of modified magnesium aluminum hydrotalcite, 6 parts of mica powder, 2 parts of dispersant, 2 parts of anti-settling agent and water 40 servings.

[0026] The preparation method of modified magnesium aluminum hydrotalcite comprises the following steps:

[0027] Add magnesium aluminum hydrotalcite and silicon nitride into dimethyl sulfoxide, carry out ultrasonic dispersion to obtain a dispersion liquid, raise the temperature of the dispersion liquid to 70°C, then add KH560 and water in turn, stir for 8 hours, cool down to 50°C and then Add diethyl chlorophosphite to react for 6h. The mass ratio of silicon nitride to magnesium aluminum hydrotalcite is 1:8, the mass ratio of KH560 to magnesium aluminum hydrotalcite is 1:25, and the m...

Embodiment 3

[0029] A water-based high temperature resistant paint, calculated in parts by weight, comprises the following components:

[0030] 50 parts of epoxy modified silicone resin, 15 parts of benzyl silicone resin, 4 parts of crosslinking resin, 16 parts of modified magnesium aluminum hydrotalcite, 3 parts of mica powder, 5 parts of dispersant, 5 parts of leveling agent and water 60 servings.

[0031] The preparation method of modified magnesium aluminum hydrotalcite comprises the following steps:

[0032] Add magnesium aluminum hydrotalcite and silicon nitride to dimethyl sulfoxide, carry out ultrasonic dispersion to obtain a dispersion liquid, raise the temperature of the dispersion liquid to 90°C, then add KH550 and water in turn, stir for 4 hours, cool down to 60°C and then Add diethyl chlorophosphite to react for 3h. The mass ratio of silicon nitride to magnesium aluminum hydrotalcite is 1:6, the mass ratio of KH550 to magnesium aluminum hydrotalcite is 1:20, and the mass rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com