Color asphalt warm-mixing agent and preparation process thereof

A preparation process and technology of colored asphalt, which is applied in the field of asphalt warm mix agent, can solve the problems of insufficient viscosity reduction of high-viscosity binders and the influence of cohesive force, so as to reduce the construction temperature and ensure the use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

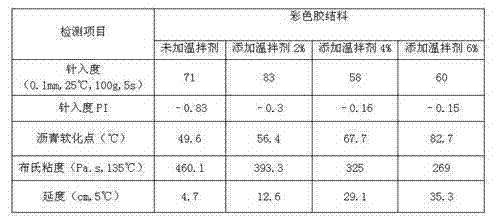

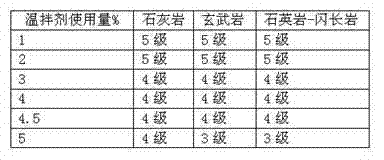

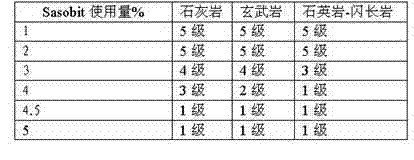

Examples

Embodiment 1

[0028] Example 1: A colored asphalt warm mix agent is prepared by mixing and melting 48 kg of polyethylene wax, 48 kg of calcium stearate, and 4 kg of silicon dioxide, extruding and granulating.

[0029] The preparation process of the colored asphalt warm mix agent is as follows: first clean the mixing and stirring equipment, and then add 48 kg of polyethylene wax, 48 kg of calcium stearate, and 4 kg of silicon dioxide to the mixing equipment through the feeding pipeline After being heated to 140°C, it is extruded and granulated through a plastic extrusion granulator.

[0030] The process of using the colored asphalt warm mix agent to prepare warm mix asphalt mixture is as follows: first mix 100 kg of Add colored asphalt into the mixing equipment, heat to 170°C, start strong stirring, then add 4 kg Color asphalt warm mix agent, just mix for 30 minutes.

Embodiment 2

[0032] A colored asphalt warm mix agent is prepared by mixing and melting 48kg polyethylene wax, 49kg calcium stearate and 3kg silicon dioxide, extruding and granulating.

[0033] The preparation process of the colored asphalt warm mix agent is as follows: first clean up the mixing and stirring equipment, then add 48kg of polyethylene wax, 49kg of calcium stearate, and 3kg of silicon dioxide into the mixing equipment through the feeding pipeline, and heat After reaching 140°C, pass through a plastic extrusion granulator, extrude and granulate.

[0034] The process of using the colored asphalt warm mix agent to prepare warm mix asphalt mixture is as follows: first mix 100 kg Add colored asphalt into the mixing equipment, heat to 170°C, start strong stirring, and then add 6 kg Color asphalt warm mix agent, just mix for 30 minutes.

Embodiment 3

[0036] A colored asphalt warm mix agent is prepared by mixing and melting 49kg of polyethylene wax, 49kg of calcium stearate and 2kg of silicon dioxide, extruding and granulating.

[0037] The preparation process of the colored asphalt warm mix agent is as follows: first clean the mixing and stirring equipment, and then add quantitative polyethylene wax, calcium stearate, and silicon dioxide to the mixing equipment through the feeding pipeline, and heat it to 140°C , through a plastic extrusion granulator, extruded and granulated.

[0038] The process of using the colored asphalt warm mix agent to prepare warm mix asphalt mixture is as follows: first mix 100 kg Add colored asphalt into the mixing equipment, heat to 170°C, start strong stirring, and then add 6 kg Color asphalt warm mix agent, just mix for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com