Casting method of large size hole defect less TiA1 base alloy ingot

A base alloy, large-size technology, applied in the field of melting and casting of TiAl-based alloy ingots, can solve the problems of inability to accurately control the volatilization loss of low melting point elements, uneven composition of ingots, difficulty in obtaining ingots, etc., and achieve easy alloy composition accuracy , Guarantee the dosage of alloy components and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

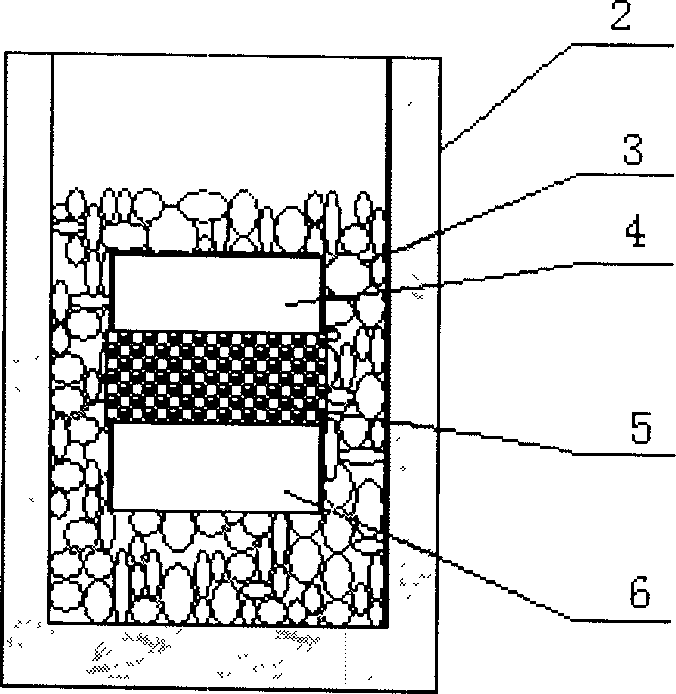

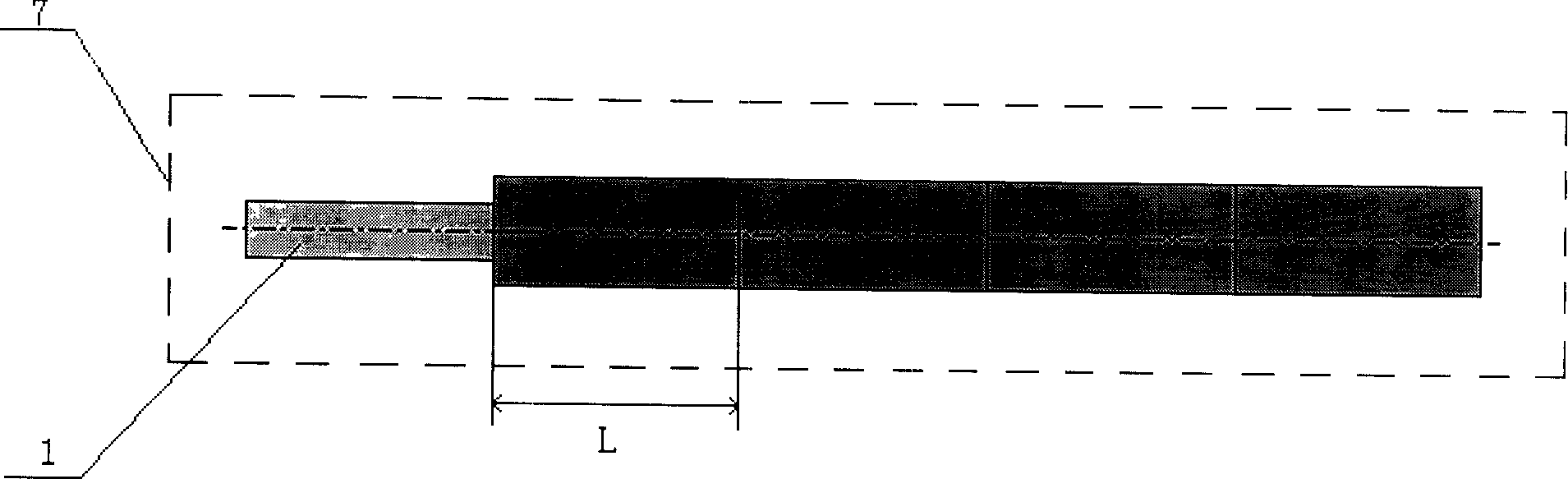

[0006] Specific embodiment one: combine 1, figure 2 , image 3 Describe this embodiment, this embodiment is completed by the following two steps: a, using water-cooled copper crucible 2 vacuum induction shell melting technology to melt and cast TiAl-based alloy consumable electrode; b, using vacuum consumable electrode arc melting technology to remelt The TiAl-based alloy electrode prepares the TiAl-based alloy ingot; the described water-cooled copper crucible 2 vacuum induction shell melting and casting technology melting and casting the TiAl-based alloy consumable electrode is completed by the following steps: a', the melting of the TiAl-based alloy raw material: the sponge titanium 3 Put it in the water-cooled copper crucible 2 and place it well. The upper end of the sponge titanium 3 is 1 / 4 to 1 / 3 from the top of the water-cooled copper crucible 2. Then put the lower aluminum block 6, the intermediate alloy 5, and the upper aluminum block 4 Embed in the middle of the tit...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 , figure 2 , image 3 Describe this embodiment, the difference between this embodiment and specific embodiment one is: in the a' step of this embodiment, the upper end of sponge titanium 3 leaves 1 / 3 space from the top of water-cooled copper crucible 2, will accommodate water-cooled The vacuum chamber of the copper crucible 2 is evacuated to 0.5Pa, filled with argon gas to 850Pa, and then evacuated to 0.5Pa, and this is repeated three times. The vacuum degree of the vacuum chamber containing the water-cooled copper crucible 2 is always kept at 0.5Pa. 2, the frequency of the power supply is 6kHz, the power supply is 300kW, the power supply is increased at a rate of ≤0.5kW / s, and the temperature is kept for 10 minutes, and then the power is reduced to 250kW, and the temperature is kept for 5 minutes; in step b', the length L of each pouring electrode is 30 cm, the pouring temperature is 1600°C, and the poured TiAl-...

specific Embodiment approach 3

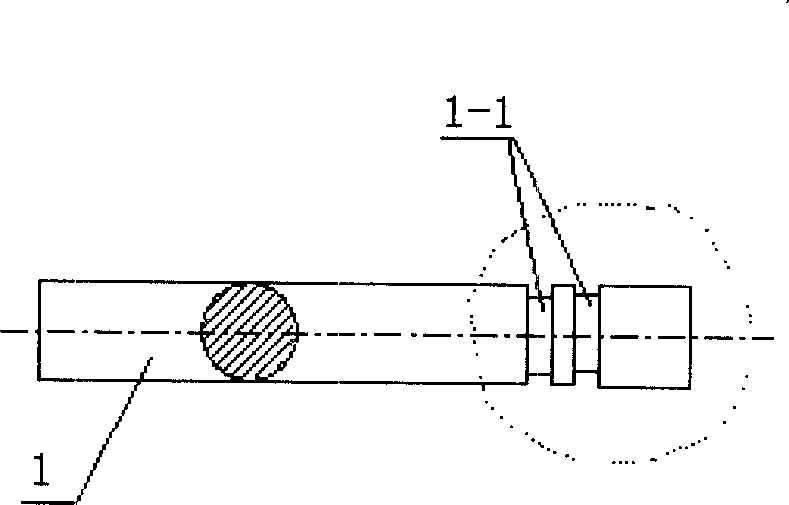

[0008] Specific implementation mode three: combination figure 2 , image 3 This embodiment will be described. The electrode head 1 of this embodiment is made of TC4 alloy material. The electrode head 1 made of the alloy material has good strength and is easy to clamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com