Spring surface acoustic wave apparatus and communications equipment

A surface acoustic wave and filter technology, applied to electrical components, impedance networks, etc., can solve problems such as difficult to ensure heat dissipation routes, difficult heat dissipation measures, poor power resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

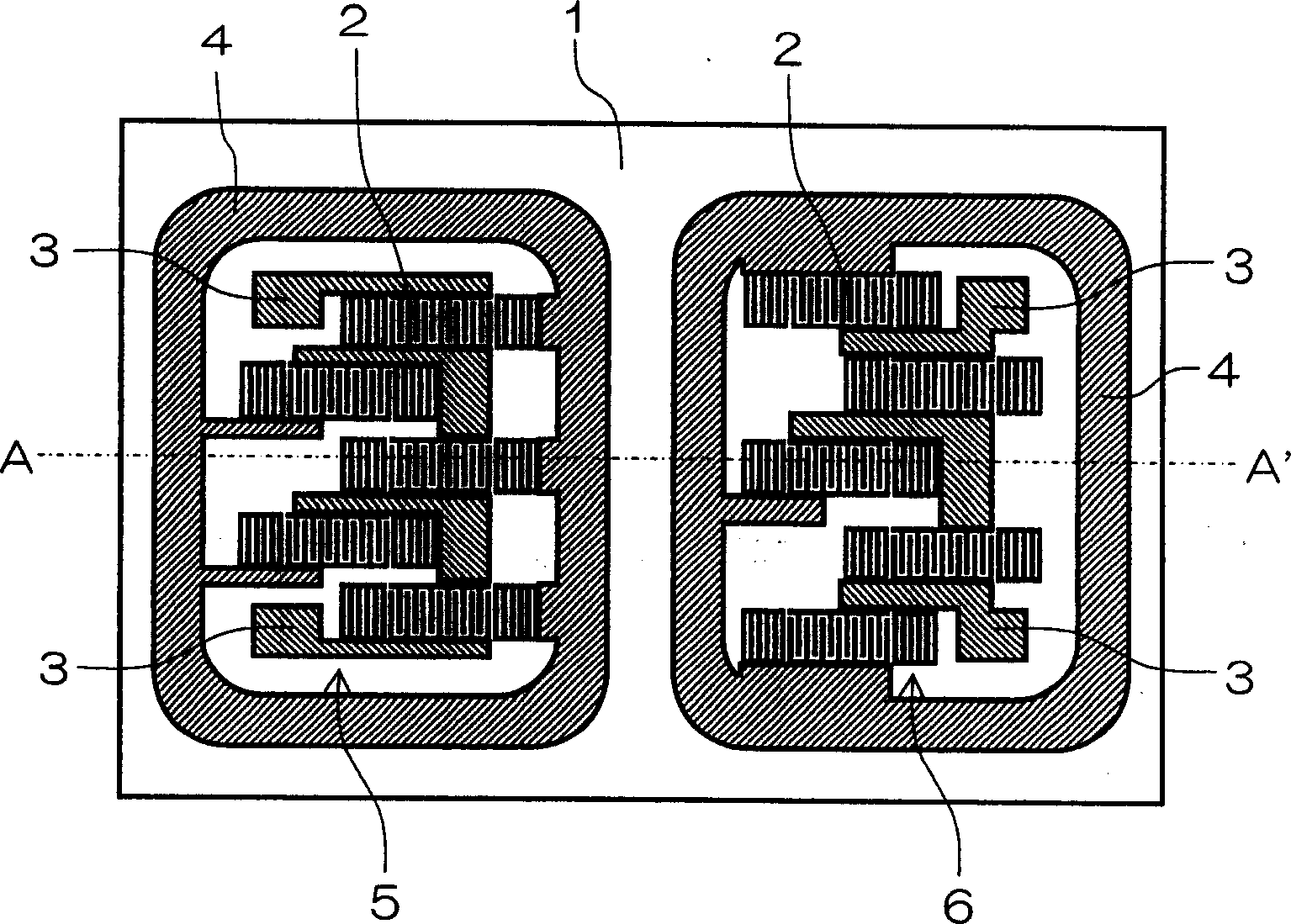

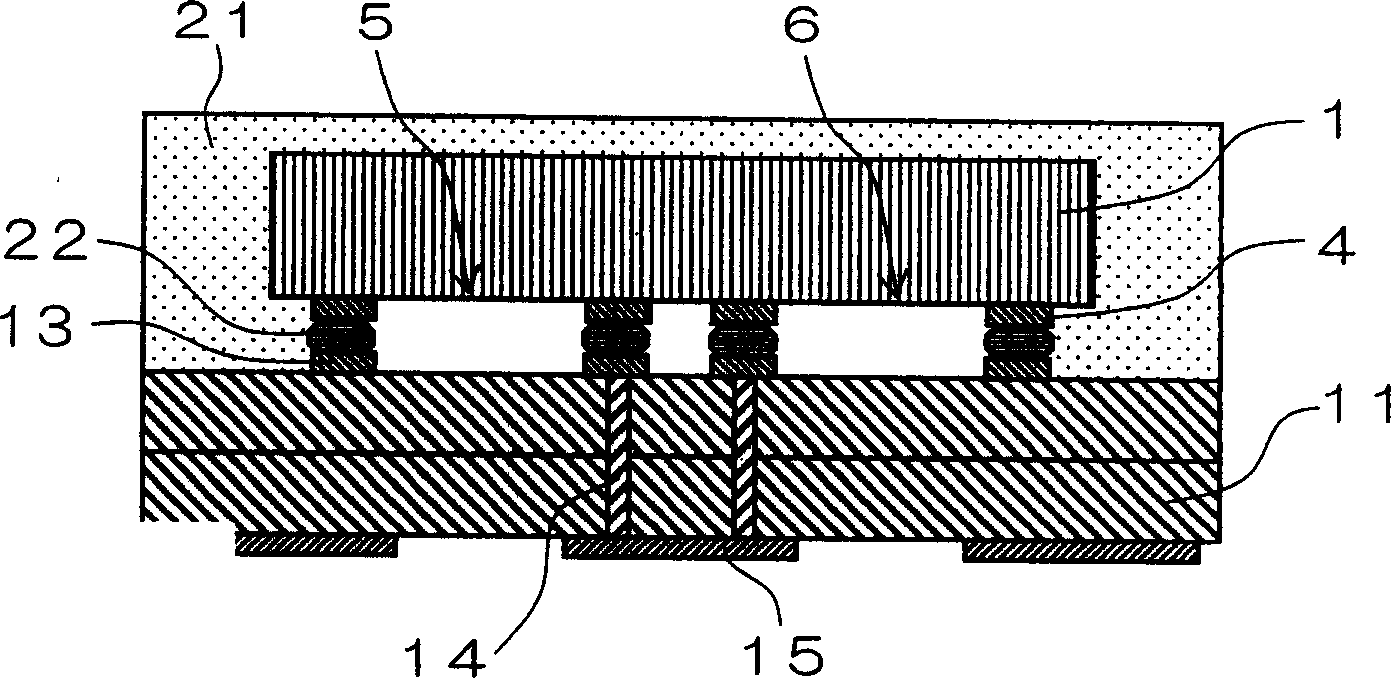

[0105] The piezoelectric substrate uses a lithium tantalate single crystal substrate that is transmitted in the 38.7°Y-tangential X direction. On one side of the main surface, an IDT made of an Al alloy of Al (99% by mass)-Cu (1% by mass) is formed. The pattern of the electrode 2, the pattern of the electrode pad as the input / output electrode, the pattern of the wiring electrically connecting them, and the ring electrode. These patterns are made as follows. After forming an Al alloy thin film by sputtering, photolithography is performed by a stepper exposure device, a spin coating device, and a developing device. After that, etching is performed by an RIE (reactive ion etching) device. In this way, given individual pattern formations are performed.

[0106] First, the lithium tantalate wafer serving as the piezoelectric substrate is ultrasonically cleaned with an organic solvent such as acetone or IPA (isopropyl alcohol), to clean the organic components. Next, after the subst...

Embodiment 2

[0118] Next, compare Figure 10 Another embodiment of the present invention will be described.

[0119] The piezoelectric substrate 1 uses a lithium tantalate single crystal substrate with a 36° Y-cut X transmission direction, and its chip size is 1.1 mm×1.5 mm. On the piezoelectric substrate 1, an IDT electrode 2, an input / output pad electrode 3, a ground pad electrode 4, a reflector 9, and a lead electrode 10 made of an Al-Cu alloy with a thickness of 1800 Å are formed by sputtering. The connecting wire 16 and the ring electrode 4 are photoresisted by a component device, a spin coating device, a developing device, etc., and then etched by a RIE (reactive ion etching) device to form a given pattern.

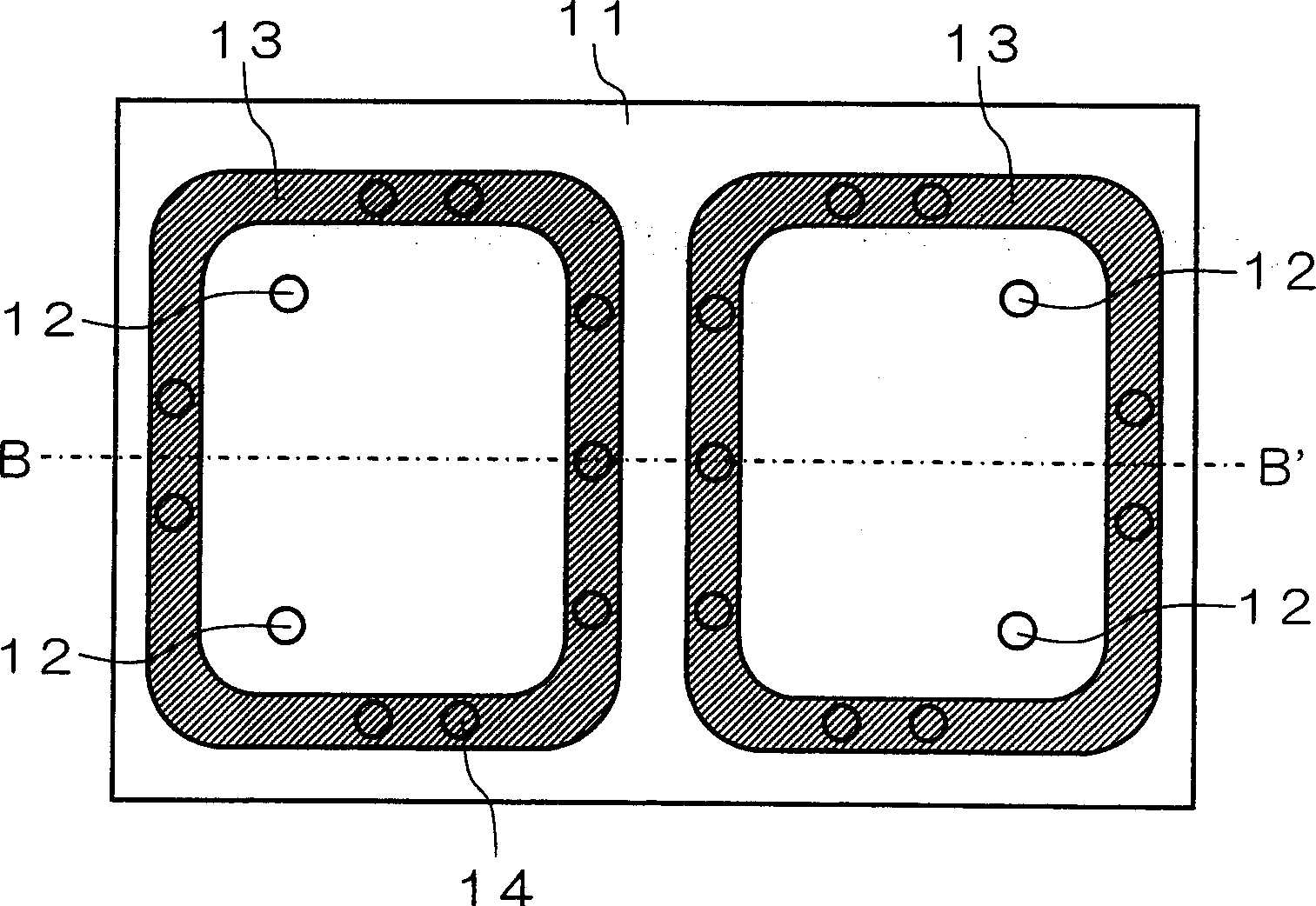

[0120] As the circuit board 11 , an LTCC (Low Temperature Co-fired Ceramics: Low Temperature Co-fired Ceramics) substrate with a substrate size of 70 mm×70 mm and a thickness of 250 μm was used.

[0121] On circuit board 11 , penetrating conductor 12 and sealing ring conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com