Circuit device

A technology for circuit devices and circuit components, applied in circuits, circuit substrate materials, printed circuit components, etc., can solve the problems of large thermal expansion coefficient difference, poor thermal expansion coefficient difference, and resin layer peeling of IC chip 104

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

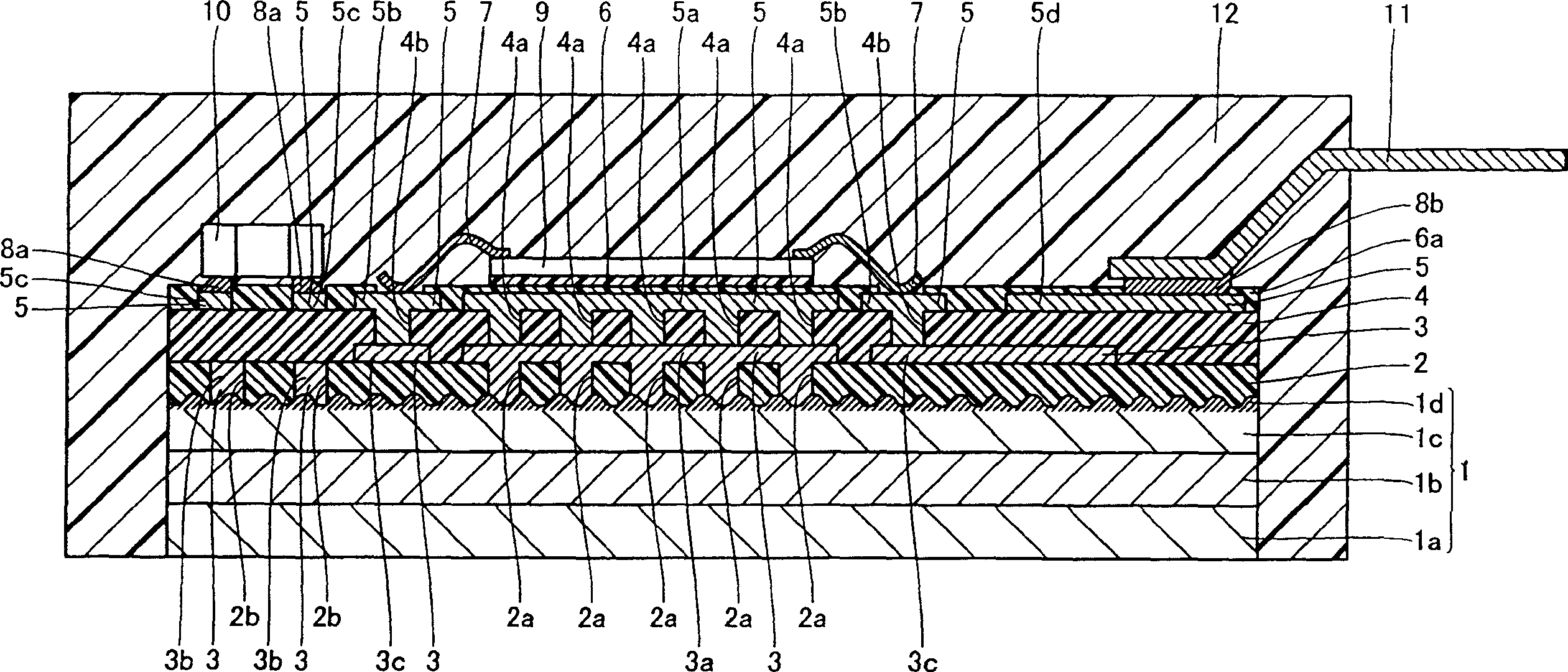

[0041] Embodiments of the present invention will be described below with reference to the drawings.

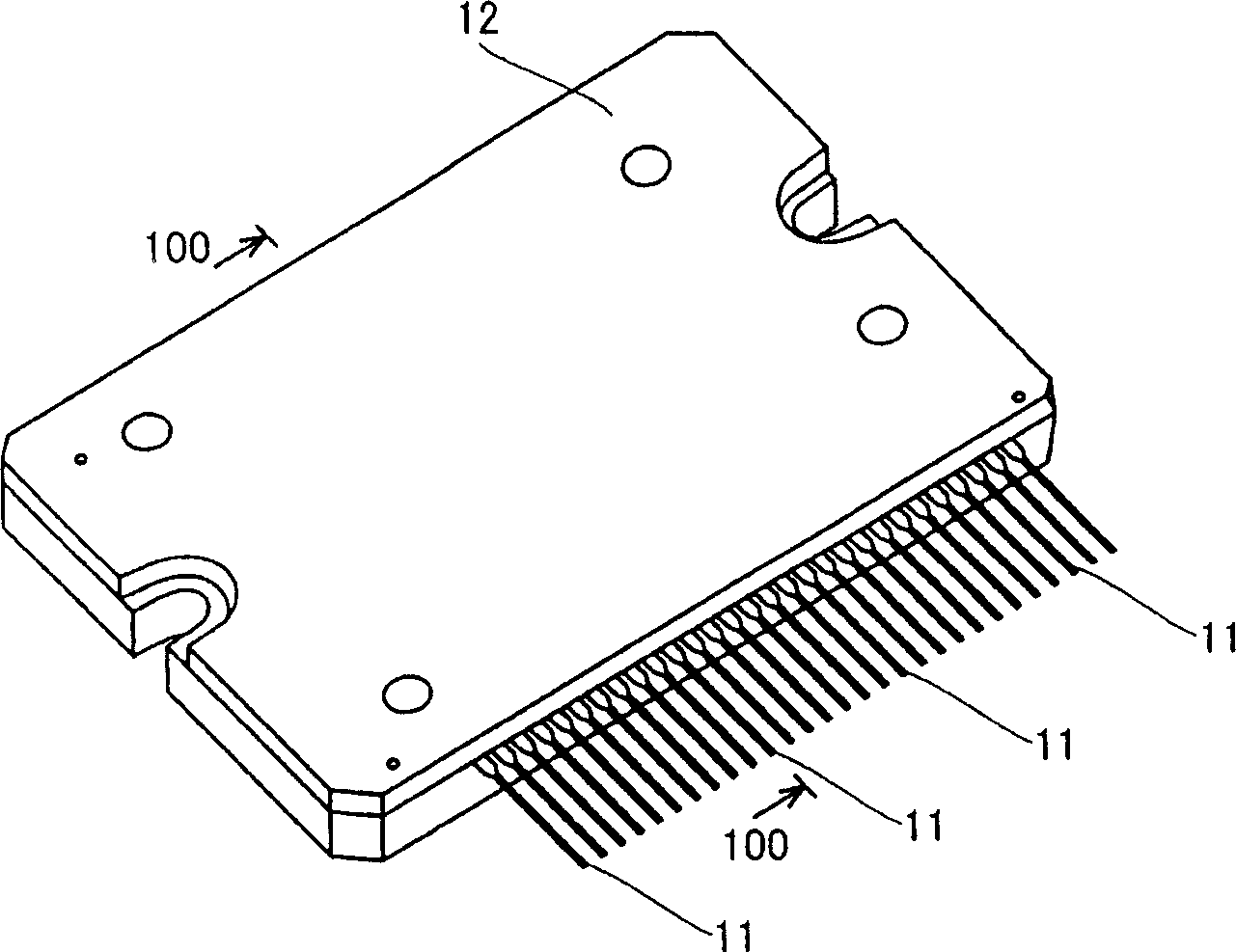

[0042] First, refer to figure 1 and figure 2 The structure of the hybrid integrated circuit device of this embodiment will be described.

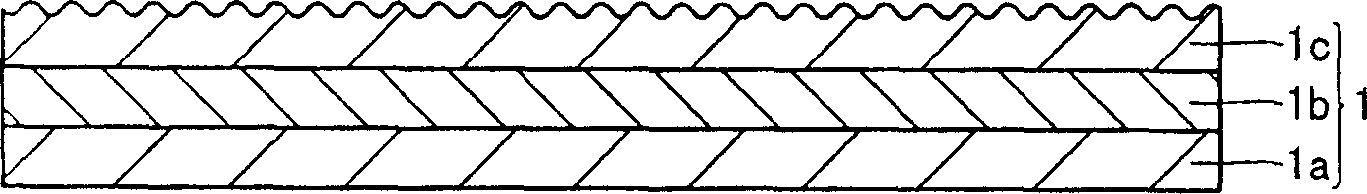

[0043] In the hybrid integrated circuit device of this embodiment, such as figure 2 As shown, a substrate 1 having a multilayer structure (three-layer structure) having a thickness of about 100 μm to about 3 mm (for example, about 1.5 mm) was used. This substrate 1 is composed of a lower metal layer 1a made of copper, an intermediate metal layer 1b made of a Fe-Ni alloy (so-called iron-nickel alloy) formed on the lower metal layer 1a, and an intermediate metal layer 1b formed on the lower metal layer 1a. The cladding material of the upper metal layer 1c composed of copper is formed. The lower metal layer 1a and the upper metal layer 1c made of copper have a thermal expansion coefficient of about 12 ppm / °C. In addition, the intermedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com