Method for preparing emulsion for rolling copper and copper alloy

An emulsion, copper alloy technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of unstable emulsification and dispersion of ingredients, residual stains on the surface of strips, incomplete annealing and volatilization, etc., to control corrosion and pollution. , easy demulsification, good lubricity and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

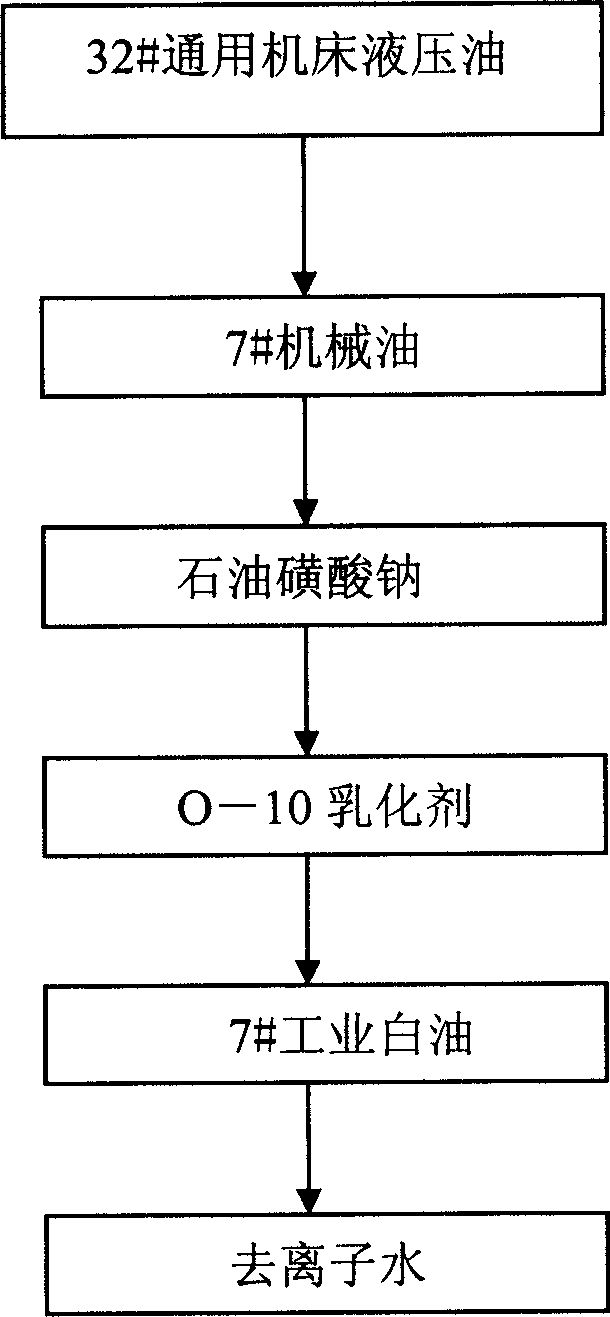

[0019] When rolling the copper grade in the middle is H65, when the batch number 5066011 brass strip, its entrance thickness is 1.8mm, and the exit thickness is 0.6mm, which is completed in 5 rolling passes; for this purpose, prepare 1000 kg of emulsion. First prepare emulsified oil by adding 10% of 32# general machine tool hydraulic oil to the container, then add 70% of 7# mechanical oil, 5% of sodium petroleum sulfonate, 10% of O-10 emulsifier, 5% of For 7# industrial white oil, use a stirrer to stir continuously and use an electric heater to control the temperature during the preparation. The stirring time is 60 minutes, and the heating temperature is 50°C. Then add the prepared emulsified oil into 90% deionized water, use a stirrer to continuously stir and dilute during the preparation, and insert an electric heater for temperature-controlled heating. The stirring time is 240 minutes, and the heating temperature is 50°C. It is prepared into an emulsion suitable for rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com