Polyvinyl alcohol composite gel and its synthesis process

A polyvinyl alcohol and composite gel technology, applied in the field of polyvinyl alcohol composite gel and its synthesis, can solve the problems of complex preparation methods, difficult industrial production, and insufficient mechanical properties, and achieve simple procedures, easy control, and immobilization high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

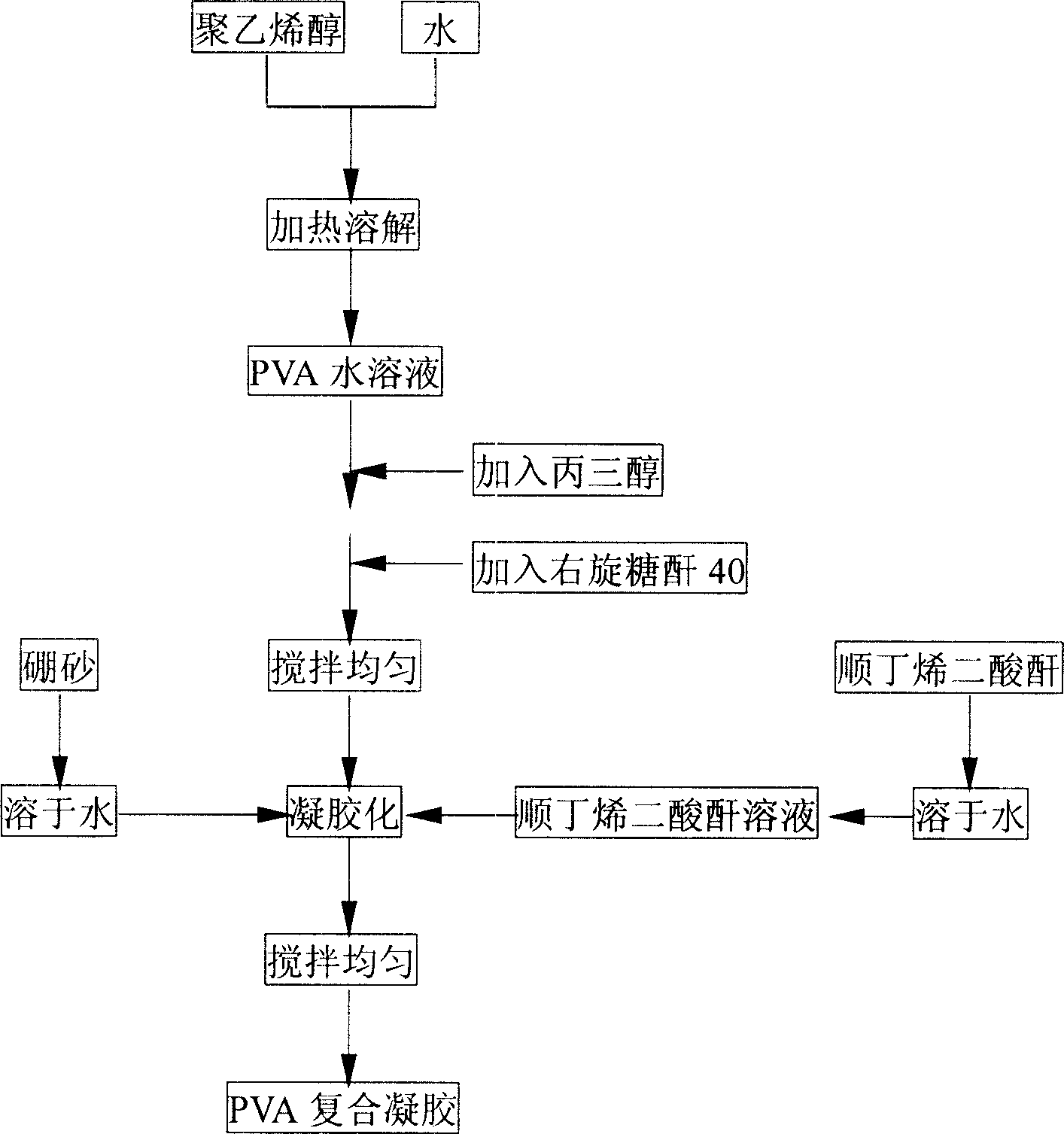

Method used

Image

Examples

Embodiment 1

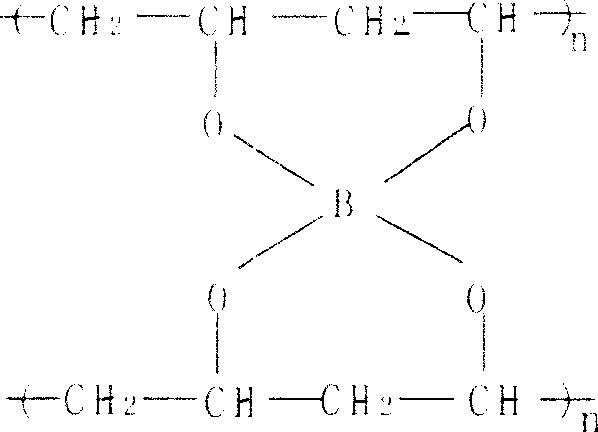

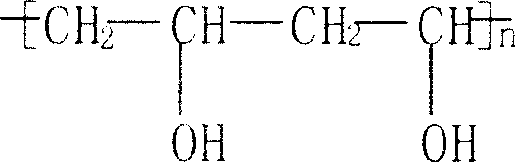

[0025] Dissolve 8 parts of polyvinyl alcohol with a degree of alcoholysis of 99% (produced by Lanzhou Fiber Nylon Factory, with a degree of polymerization of 1750±50) into 100 parts of water at 85°C, stir while adding, and then add 4.4 parts of acrylic acid after the polyvinyl alcohol is completely dissolved. Triol, after stirring evenly, add 1 part of dextran-40 (dissolved in a small amount of water in advance), stir evenly, and then add 1 part of borax that has been dissolved while stirring continuously, and stir while adding, to carry out gelation After 2 to 5 minutes, slowly add 1 part of maleic anhydride solution, and keep stirring until there is no flocculent coagulation in the gel solution, and a transparent, slightly milky white viscous sol is obtained, which is polyvinyl alcohol For the composite gel, the above operations were all carried out at a constant temperature of 85°C. The composite gel liquid was frozen at -24°C and thawed at room temperature.

Embodiment 2

[0028] Repeat Example 1 with the following differences: 10 parts of polyvinyl alcohol with a degree of alcoholysis of 99% are dissolved in 100 parts of water at 85°C. Compared with "Example 1", the viscosity of the obtained composite gel solution is increased by 2.1%, the pore diameter and porosity of the carrier are slightly reduced, and the carrier strength is better.

Embodiment 3

[0030] Repeat Example 1 with the following differences: use 15 parts of polyvinyl alcohol with a degree of alcoholysis of 99% to be dissolved in 100 parts of water at 85°C. Compared with "Example 2", the viscosity of the obtained composite gel solution increased by 1.6%, and the pore diameter and porosity of the carrier decreased. The mechanical strength of the carrier after freeze forming is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com