Technique of enzyme method for treating organic wastewater and matched equipment

An organic wastewater and enzymatic treatment technology, applied in the fields of biochemical engineering and environmental science, can solve the problems of failure to reduce investment in environmental protection equipment and facilities, unreported processes and devices, waste of land resources and energy, etc. Strong pollution ability, good immobilization effect, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

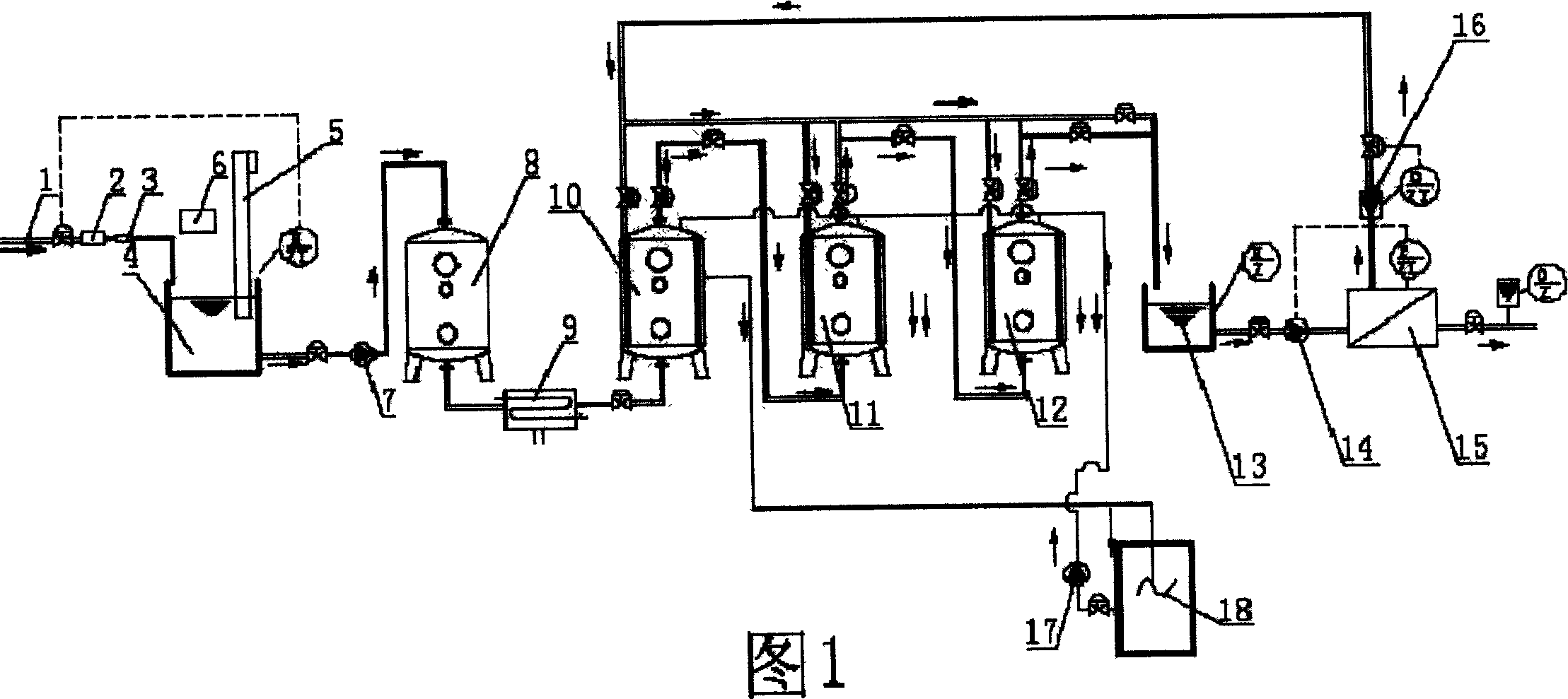

[0017] This embodiment is realized in this way: the waste water enters the storage tank 2 from the water inlet 1, flows through the grid 3 to remove larger suspended solids, and then enters the adjustment tank 4. The device 6 adjusts the pH and maintains it at 4.5-5.5; the wastewater after the pH adjustment is pumped into a preprocessor 8 by the raw water pump 7 for adsorption and interception of the filter medium; the pretreated wastewater is passed through the temperature control device 9 to maintain the wastewater at After 25-50°C, it enters the first-stage immobilized enzyme reactor 10 from the bottom by way of ascending flow, and then flows through the second-stage immobilized enzyme reactor 11 and the third-stage immobilized enzyme reactor 12. The residence time of the wastewater is 1 ~ 3 hours; the effluent degraded by the enzyme-catalyzed reaction enters the transition pool 13, and is sent to the filter device 15 by the booster pump 14; the concentrated water intercepte...

Embodiment 2

[0024] According to the process and device of Embodiment 1, 2 tons / hour of industrial organic wastewater is treated, wherein the capacity of the regulating tank is set at 6 to 15 tons; the pretreatment adopts a precision filter, which is 2 cubic meters / hour, and its shell is made of stainless steel material.

[0025] The waste water enters the enzyme reactor after the online PH value and temperature adjustment of the front-end regulating tank and the filtering of impurities and some large suspended solids, and the water is fed from the bottom using an upflow type. The hydraulic retention time of the reactor is 1.5 hours, and the water is discharged Finally, it enters the filtrate pool, and then the pressurized pump connected to the pool sends water into the ultrafiltration machine. The membrane pore size of the ultrafiltration machine is 50,000 to 80,000 molecular weight. 70% of the passed water is discharged straight to the standard, and 30% of the concentrated water is retur...

Embodiment 3

[0027]Take the industrial wastewater of a printing and dyeing factory that processes 2,000 tons per day as an example. The volume of the sedimentation tank is 300-500 cubic meters, and a pipeline jet mixer is installed on the waste water outlet pipe to directly pump the prepared medicine into the pipeline at high pressure to adjust the pH value. After the grid and PH adjustment, the adjustment tank section can add flocculants, decolorizers, etc. for pretreatment, and the water is sent to the filter device with a processing capacity of 100T / h. The device can be used in two ways, using the inner brush drum filter , the filter area is 8 square meters, the diameter is 800CM, the length is 3 meters, the water flow speed is 10 m / s (filter device with a filtration speed of 8-15 m / s), and then the water temperature is adjusted to 30-50°C (it is not necessary to install this device in southern regions and in summer), and the outlet temperature of printing and dyeing wastewater is gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com