Preparation of organic-inorganic hybridized nanometer microcapsule with organic micromolecular hydrocarbon as model plate

A nano-microcapsule, small molecular hydrocarbon technology, applied in microcapsule preparations, microsphere preparation and other directions, can solve the problems of limited assembly efficiency, inability to stably disperse, limited application scope, etc., and achieves wide application scope, simple preparation process, permeability Properties controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

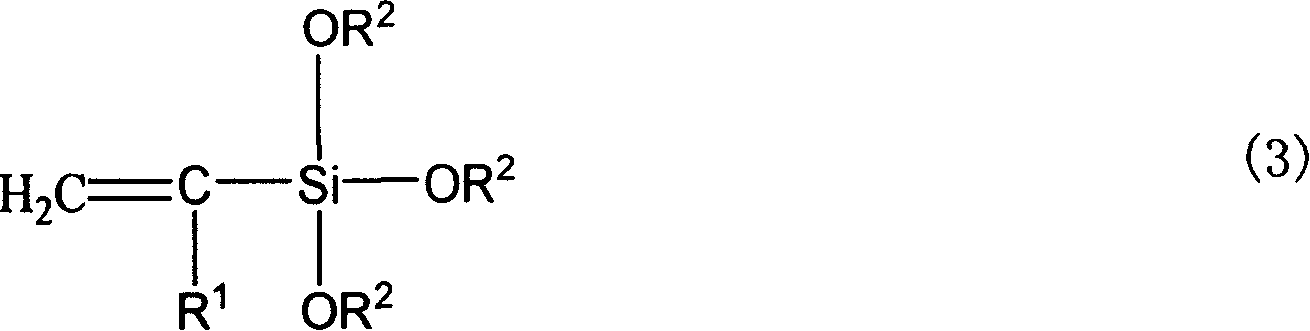

Method used

Image

Examples

Embodiment 1

[0044] Weigh 0.4 g of emulsifier sodium dodecyl sulfonate, 1 g each of pH buffering agents sodium dihydrogen phosphate and diammonium hydrogen phosphate; add to 1000 g of water to obtain an emulsifier solution with a pH value of 7. Mix 10g of octane, 0.6g of hexadecane, 1.5g of styrene, and 0.5g of 3-trimethoxysilyl propyl methacrylate, add them to the above-mentioned aqueous solution containing emulsifier and pH buffering agent, and ultrasonically shake the above-mentioned The mixed solution was dispersed to obtain a stable emulsion; the temperature was adjusted to 80°C, under the protection of nitrogen, 0.2 g of potassium persulfate was added to initiate polymerization, and after 45 minutes of reaction, it was kept at the reaction temperature for 60 minutes. The number-average particle diameter measured by a dynamic light scattering particle size analyzer is 51.2nm, and its morphology is observed by a transmission electron microscope, which shows that it is a hollow microcaps...

Embodiment 2

[0046] Weigh 4 g each of emulsifier sodium dodecyl sulfonate and OP-10, and 1 g each of pH buffer agents sodium dihydrogen phosphate and diammonium hydrogen phosphate; add 1000 g of water to obtain an emulsifier solution with a pH value of 7. Mix 200g of cyclohexane, 6g of hexadecane, 60g of styrene, and 40g of 3-trimethoxysilyl propyl methacrylate, add them to the above-mentioned aqueous solution containing emulsifier and pH buffering agent, and use ultrasonic waves to shake the above-mentioned mixture Disperse to obtain a stable emulsion; adjust the temperature to 50°C, under the protection of nitrogen, add 10 g of potassium persulfate to initiate polymerization, react for 240 minutes, and keep warm at the reaction temperature for 60 minutes. The number-average particle size measured by a dynamic light scattering particle size analyzer is 78.5nm, and its morphology is observed by a transmission electron microscope, which shows that it is a hollow microcapsule.

Embodiment 3

[0048] Weigh 1 g of emulsifier sodium dodecyl sulfonate, 40 g of pH buffer agent sodium acetate, and 10 g of acetic acid; add 1000 g of water to obtain an emulsifier solution with a pH value of 5. Mix 500g of pentane, 100g of cetyl alcohol, 490g of styrene, and 10g of methyltriethoxysilane, add them to the above aqueous solution containing emulsifier and pH buffer, and disperse the above mixed solution with ultrasonic waves to obtain a stable emulsion ; The temperature was adjusted to 25° C., and under the protection of nitrogen, 0.2 g of hydrogen peroxide and 0.8 g of ferrous chloride were added to initiate polymerization, and after 300 min of reaction, the temperature was kept at the reaction temperature for 60 min. The number-average particle diameter measured by a dynamic light scattering particle size analyzer is 115.8nm, and its morphology is observed by a transmission electron microscope, which is a hollow microcapsule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com